Rope Application, Installation and Maintenance

Apr 1, 2014

The challenge of maintaining elevator ropes is best met by a step-by-step process.

The performance (life or service time) of elevator ropes is a very significant maintenance concern for elevator-maintenance companies, industry consultants and building/property owners alike. In terms of maintenance costs, this issue is one of the largest single costs for the elevator industry today. In terms of interruption of service, it causes extended loss of individual elevator service. Waiting for replacement ropes and completing the installation takes at least several days and can extend to many weeks. We can consider this problem with the acronym “AIM”: looking at the application (or overall system), then the installation and related maintenance of the hoisting system of a traction elevator.

Application

The first step is the most involved and complex. To keep this topic simple, note that much has already been written, reviewed and published in ELEVATOR WORLD and many other places in the industry. The first and most important point to make is that the decline of rope performance is not a problem with the ropes being supplied to the elevator industry; it is a system problem, and, ultimately, the solution must be a systematic one.

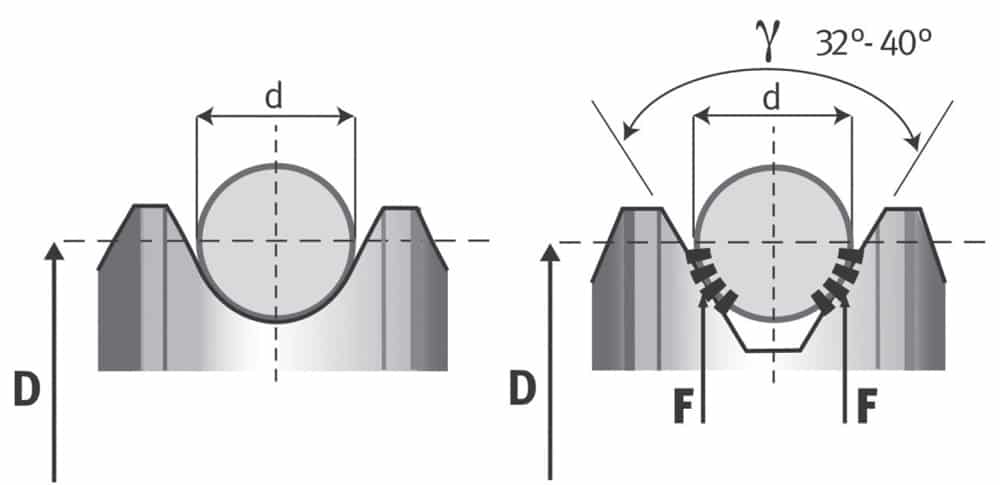

Two fundamental parts make up the foundation of the issue. The first is that the industry is using smaller drive motors and sheaves. When you look around (particularly at installed elevators where the performance problem is obvious), you see many installed systems that now use the code-allowed minimum D:d of 40:1, where the diameter of the drive sheave is 40 times the diameter of the hoist rope. This fact and trend leads to the second fundamental application aspect: smaller drive sheaves mean less sheave-to-rope contact area, and that requires aggressive drive-sheave-groove profiles in order to achieve the needed level of traction. Large undercuts or V grooves have a huge impact on the work (pressure) and performance of the rope system. Reliable research and mathematical calculation methods made by such industry experts as Dr. Klaus Feyrer have demonstrated that the largest undercut or steepest V-groove profile, alone, will reduce expected rope life by more than 90%.

Aggressive profiles increase groove pressure, which increases the abrasive wear and work on the ropes. Add to this the fact that many systems, for various system-application- and installation-related reasons, now also include double wraps, 2:1 suspension or more, and diverting sheaves. Also note that reverse-bend designs have a large impact on their own. Each of these factors alone (but even more so in combination) increases the number of rope bends or increases the normal operating speed of the rope, which then dramatically decreases the service time of the rope. For an example of the technical factors detailing these effects, see the research by Feyrer during his years at the University of Stuttgart or research by wire-rope manufacturers (EW, April 2009).

Relative to the hoisting-system differences that are common today (compared to common systems of 20-30 years ago), rope-life calculation methods are very revealing and point to the foundation of the issue. Comparative analyses have been made using the Feyrer calculation method. Legacy or vintage systems are easily found where the calculation shows that the installed rope in those older designs have effective rope-life expectancy of at least 20 years – even 40 or more years, in some cases. However, caution should be taken to avoid assumptions about life in terms of calendar time; it is best to think in terms of elevator run cycles (or numbers of rope bends) and avoid the misleading reference of time in years. The referenced calculation methods and comparisons use the run-cycle/rope-bend units.

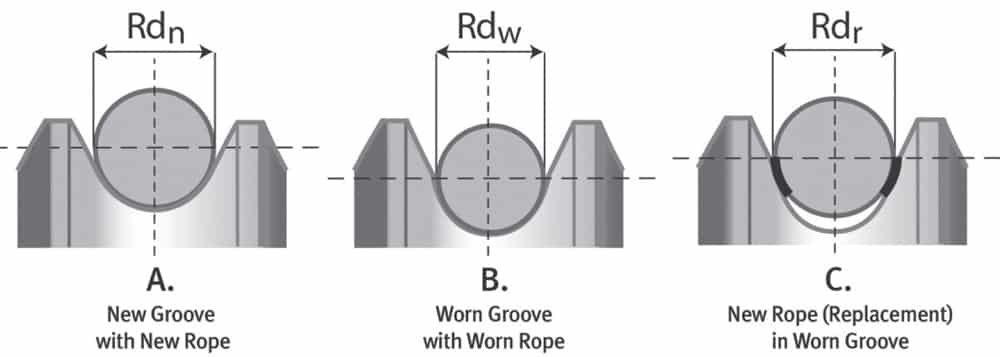

Rope-life calculations like the Feyrer method take a broad range of factors that statistically estimate rope life into account. An interesting parallel to this relates to wear in general and unequal wear of sheave grooves, which are real and observable factors in system performance. System wear (especially sheave-groove wear, among other things) can create a demanding design (the undercut effect, which, in turn, creates groove pressure on the rope), both on its own and on top of other negative impacts on the system.

Today’s hoisting systems using the same calculation methods as those used for older systems can have effective rope-life expectancy of approximately two years. This is significantly less than that of vintage systems. The industry must understand that this issue is mainly about the application and design of the suspension system — not about the quality of the rope being used. There are better rope designs available that are more resilient. They include multiple-layer ropes (mixed cores, independent wire-rope cores [IWRCs] and full steel) and nine-strand ropes replacing the old, standard 8-X-19 sisal-core ropes. The latter are not up to the basic design demands of new elevator systems. Better and more-resiliently designed ropes are able to deliver more than double the rope-life performance. Nine-strand ropes with a mixed core (which are more flexible) will yield the best results, as opposed to nine-strand, full-steel IWRC ropes. These ropes will also help overcome or cancel out other system and wear impacts.

Installation and Maintenance

When installation and maintenance are done poorly (or, worse, done incorrectly), the compounding negative effect on rope life (already expected to be short) is unavoidably dramatic. Consider compounding negative impacts on a two-year expected rope life and add the statistical reality of higher usage (either in terms of more trips or higher loading, or both). With all of the possible system impacts, other than the mentioned rope, one should not be surprised to find installations now needing their ropes replaced in very short times – sometimes in as short as six months.

Conclusion

There are two main practices related to installation and maintenance: initial correct installation of each rope in a set, then achieving and assuring an equal load is set and kept on each rope. Elevator ropes are installed by fastening the rope with shackles at each end during installation. This fact is extremely significant: if a rope is twisted or torqued during installation, that rope will experience additional stress during use.

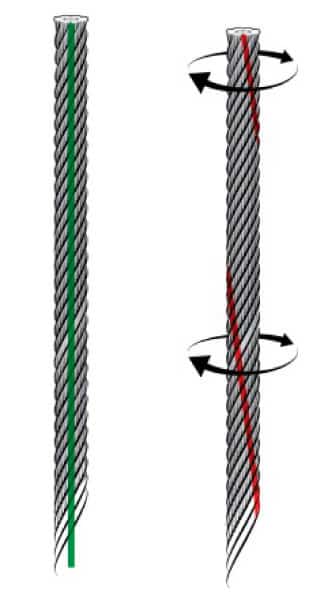

Depending on the amount of twist or torque, the performance (life) of that rope can easily be reduced by at least half. The only way to avoid this problem is to ensure every rope installed is done so without any compromising torsion. Use only ropes with a painted reference line (sometimes called an “i-line”) to ensure correct installation. Immediately after installation, a simple diagnostic verification is to observe turns of the painted line at the drive sheave as the elevator runs. There will be extra torsion on a rope with too many turns.

Finally, there is the installation and maintenance issue known as “equal rope load.” Variation in load will have much the same impact on rope performance as torsion. This is also a safety issue, as the 2013 code now requires tension on all ropes to be within 10% of their proportional individual loading. We have systems that put the highest demands on the hoist ropes from the beginning. The industry is becoming aware that any installation and maintenance done incorrectly are big negatives working against an already low potential. There is much for the industry to know and understand about elevator hoisting-system performance. The major issues and impacts discussed in this article should have given its readers the first and important facts they need to take “AIM” at the problem.

Negative effects such as undercut dynamically add to an already difficult situation, further underscoring the importance of “perfect” installation. Unfortunately, ropes are often twisted or not equalized.

Ropes designed for higher performance (like the one on the right) are necessary for extended rope life.

Rope twisting/torquing

Get more of Elevator World. Sign up for our free e-newsletter.