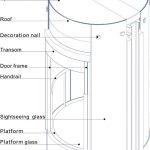

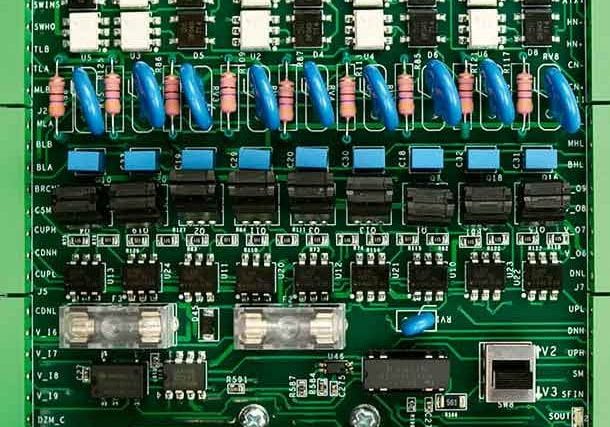

ZheJiang GIANT Holding Co., Ltd., operating in China since 1978, has focused its R&D experience into creating a fully round panoramic car named Curling. While the driving mode of the lift usually selects the hydraulic drive, this machine-room-less (MRL) lift has a traction ratio of 2:1. In an installation in Kunshan, China, this brought a series of challenges to our project team. We arranged components such as the traction machine, counterweight, governor, hoistway signal and trailing cable in inconspicuous/hidden positions. In consideration of installation or replacement of the car glass, the shaft curtain wall is designed to be detachable as far as possible.

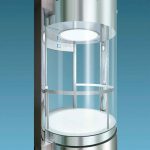

We needed a bold, creative vision at the beginning of the project. As simply as possible, the fully round car was abstracted into a glass tube. Because of the need to install the door system, two door frames were required to be added at the entrance. A large lamp was added to the car ceiling. The car operating panel (COP) is integrated with the car photoelectronic glass and is conveniently controlled by touch. The entire system is based on GB 7588 or EN 81.

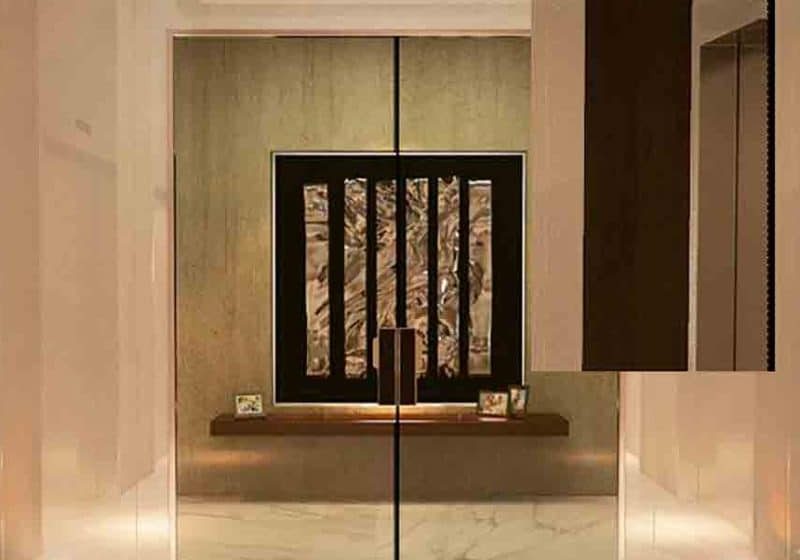

An interactive globe floor that automatically rotates with the passengers’ footsteps was designed for an improved riding experience. We moved the car supporting column to the outside of the glass, hid the sling and car guide, and used the curved mirror stainless steel as decoration. The steel reflects the surroundings through its arced surface, and passengers can get the maximum view. These designs resulted in Curling A (Figures 1 and 2).

Force on the Car Frame

According to the features of Curling A, the glass is connected with the top and bottom of the enclosure by structural features we call “spiders” or “decoration nails,” which give a simple appearance.

We can see from the rendering that the loadbearing parts are just the door frames. To balance the weight of the roof, the upper enclosure, door system and cartop, we needed to connect the door frames, roof and the outer column into a rigid body, which is the whole frame. By estimating the weight of the car, the car weight is much heavier than the rated load.

Considering the ride comfort, we decided to use a flexible platform structure to connect the upper enclosure, roof (ceiling), car wall (column and glass), car frame and lower enclosure into a whole. The advantage of this scheme is that the glass and frame system are relatively stationary during traveling, and only the platform and handrail move slightly, together with passengers. We used a careful selection and arrangement of shock-absorbing materials to prevent negative effects of noise and vibration.

Door System

There are upper and lower door operators available: the lower type is prettier, but, considering the adverse effects of dust and moisture generated, we decided to use the upper door operator. However, its main components needed to be hidden in the upper enclosure. For the sake of more transparency and solidity, there is no border in the middle of the glass door. However, the outside has a border, which is concealed in the door frame. To ensure the safety of passengers entering and leaving the car, light curtains in the form of a cat’s eye were used. The transmitter and receiver are mounted on the pedal and transom, respectively, adding a simplicity and seamlessness to the whole car.

Panoramic Glass Wall

The size of the front glass is 3,000 X 4,200 mm. If we use 8 + 1.52 + 8 glass, the glass weighs 550 kg or so. The processing, structure design, fixed mode, installation and replacement of such a large piece of arched glass was our main installation focus. The lower end of it is connected to the lower enclosure by spiders. Close attention was paid to avoid direct contact between the glass and metal parts, with soft material added between the glass and the metal.

COP and Floor

In light of using a design that had been verified as safe in the real world, we used a classic COP, with its buttons mounted on the handrail, and its monitor mounted on the transom. To prevent slipping, the floor surface is textured glass and can be lit. Nonslip floor glass with nanometer light material creates a fluorescent, ice-permeable atmosphere consistent with the overall style of the car. A detachable stainless-steel decorative plate around the edge of the glass is convenient for maintenance.

Upper Enclosure Roof and Ceiling

The upper enclosure on the top of the door is made of a glass plate and serves as an entrance to facilitate safe maintenance. The front and rear parts are connected by the structural parts at the side gap. This ensures balance of the elevator’s forces and appearance. The installation must ensure the horizontal and vertical structure of the whole frame (outer column, door frame, roof and upper beam). Therefore, we designed a special mechanism for the roof/upper-beam connection. The mechanism can be adjusted in three directions at the time of installation. Once in place, its position can be completely fixed. The roof and ceiling are connected by a ring of stainless-steel grille, not only to meet the requirements of ventilation and lamp replacement, but also to achieve the desired visual effect.

Platform

In view of the possible partial load of the car, a slanted beam is added between the bracket and lower girder of the car frame, and the counterbalance is hidden in the lower cover. We used a damping system and guide mechanism (which ensures the bottom of the lift is only subject to the upper and lower movements under partial load) to maintain the required 3-mm gap between the platform and down enclosure. Our barrier-free design makes the height difference between the surface of the sill and the floor.

Guardrail and Handrail

The horizontal distance between the cover and glass curtain wall should be more than 500 mm. We also designed a retractable guardrail, as the ordinary one does not meet the code requirements. In working condition, the guardrail is hidden in the upper enclosure and will be stretched out during maintenance. The handrail cannot be connected to the car wall because of the active underbody structure. Thus, we arranged the handrail mounts in a regular pentagonal to improve the handrail’s stability.

These efforts resulted in Curling B (Figure 3). This product combines technology and art and has led to our obtaining many patents. To ensure its safety and reliability, we have done many calculations and tests during trial production. Despite the difficulties in the implementation of the project, we still delivered Curling to the customers on time, thanks to careful planning early on. We won praise and thanks from the parties concerned, and sincerely appreciate the opportunity for the project and our team’s efforts.

Acknowledgements

Guanglai Liu, Huijiang Gu, Yi Wang and Wei Chen were members of the project team, composed of industrial-design and mechanical design engineers full of passion for their work in the vertical-transportation industry.

- Figure 1: Curling A

- Figure 2: Curling A (rendering)

- Figure 3: Curling B

Get more of Elevator World. Sign up for our free e-newsletter.