Nessum simplifies advanced service integration into elevators.

by Neil Bullock

images courtesy of Nessum

Overview

Building owners and managers have recognized the role that elevators play in the quality of experience in a building. In response to the increasing comfort and security requirements of building tenants, elevator systems are undergoing a transformation from being a basic utility to becoming a centerpiece. Formerly known as HD-PLC, the versatile Nessum specification (standardized as IEEE 1901) provides a robust and secure communications foundation for the integration of advanced features into elevator systems. Typical customers include OEMs in the commercial and industrial elevator business such as Otis, TK Elevator, Schindler and KONE.

Elevator Services

Buildings that offer optimal efficiency, comfort and safety will command the highest rents and occupancy rates. A variety of more advanced services have evolved for elevator systems that make an important contribution to this goal, and communications systems built using the Nessum specification provide an excellent means to support them.

Examples of elevator services include:

- Elevator Dispatch. Elevator control systems manage the dispatch of elevators to optimize the throughput of occupants from one floor to another while providing a comfortable and safe environment. They signal the location and availability of elevators and provide security, maintenance and communications services.

- Information Display. Video displays present day-to-day communications to elevator occupants and can present security information (for example, directions to emergency exits), when required.

- Wi-Fi and Cellular Service Extension. The provision of a Wi-Fi access point or a small cell for cellular networks allows the extension of the related service into the elevator cabin that is uninterrupted during travel.

- Video Surveillance. A video system provides real-time monitoring of the interior of the elevator cabin, providing a safe and reassuring environment for occupants.

- Occupancy Detection. An RF (radio frequency) sensor system counts people and discriminates between people and objects in the elevator cabin, even when the lights are out or video is obscured by smoke.

- Operator and Emergency Service Communication. Two-way audio systems facilitate communication between elevator occupants and management, as well as emergency services.

- Lighting Control. Lighting control systems can reduce energy consumption by turning off lights in the cabin when the elevator is unused and increasing or decreasing lighting levels according to the time of day.

- Heating, Ventilation, and Air Conditioning (HVAC). HVAC systems monitor and control the elevator cabin’s temperature, humidity and air quality. They optimize heating and cooling based on occupancy patterns and internal building and external weather conditions, maintaining comfort while minimizing energy usage.

Challenges of Existing Communications Technologies

Elevator control systems have generally evolved as individual services. The communication between equipment and controller has been point-to-point, the data rates have been low and the protocol is either proprietary or one of a plethora of protocols designed for point-to-point communication. Dedicated cables for each service are also heavy and costly. Several network-oriented communications technologies are now being used for elevator communication. However, they each have disadvantages that limit their application. Ethernet is used for wired data distribution, but data cable compliant with elevator traveling cable requirements is costly and can only serve shorter buildings. CAN is used for in-cabin networking, but it does not have the range to link the cabin to the machine room, and it has limited data capacity.

The environment is challenging for wireless propagation, as the cabin enclosure is composed of metal and the shaft is typically lined with concrete or steel. To move toward more efficient and effective delivery of new elevator services, what is needed is a communications system that can holistically address control across all these capabilities with appropriate capacity and range using standardized network-oriented protocols.

Nessum: A Holistic Communications Technology for Advanced Elevators

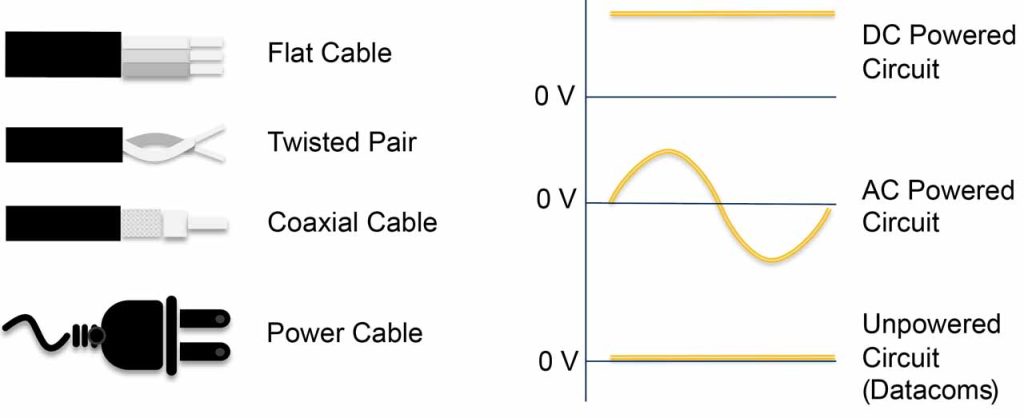

The technologies underlying Nessum provide robust data services to a wide variety of terminals at the lowest cost. Since, in most cases, the terminals must be wired to a power source, this is most effectively achieved by transmitting the data over the power lines.

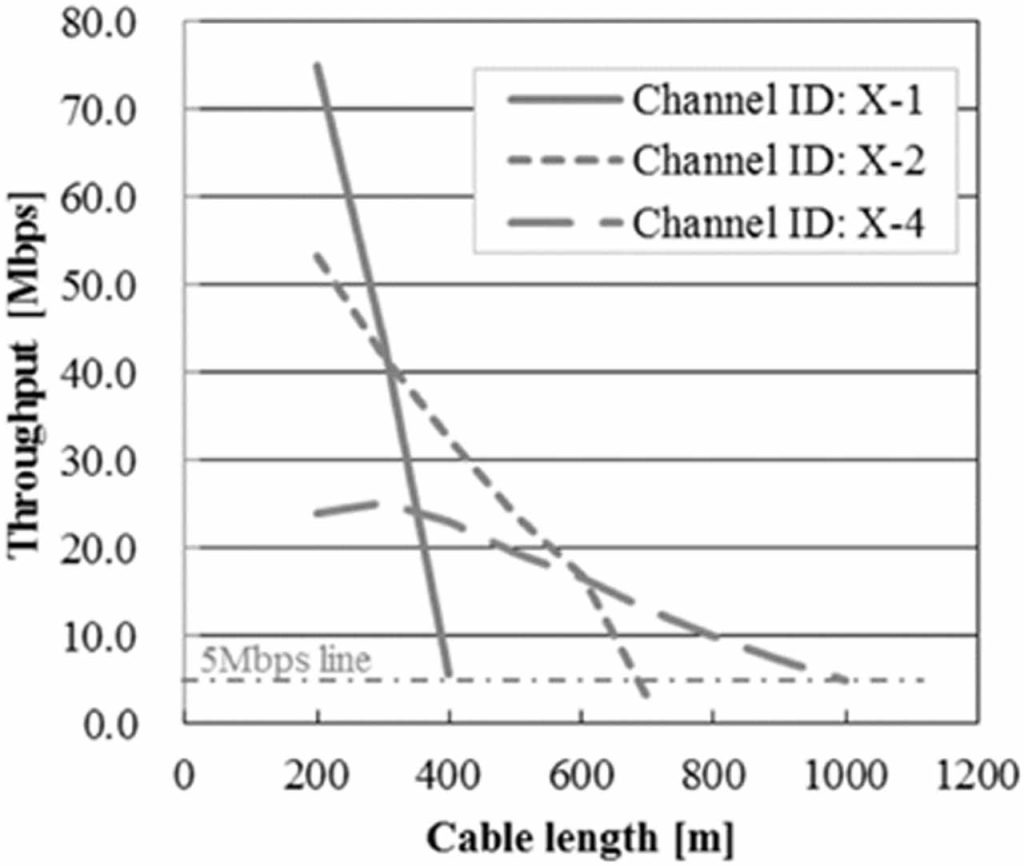

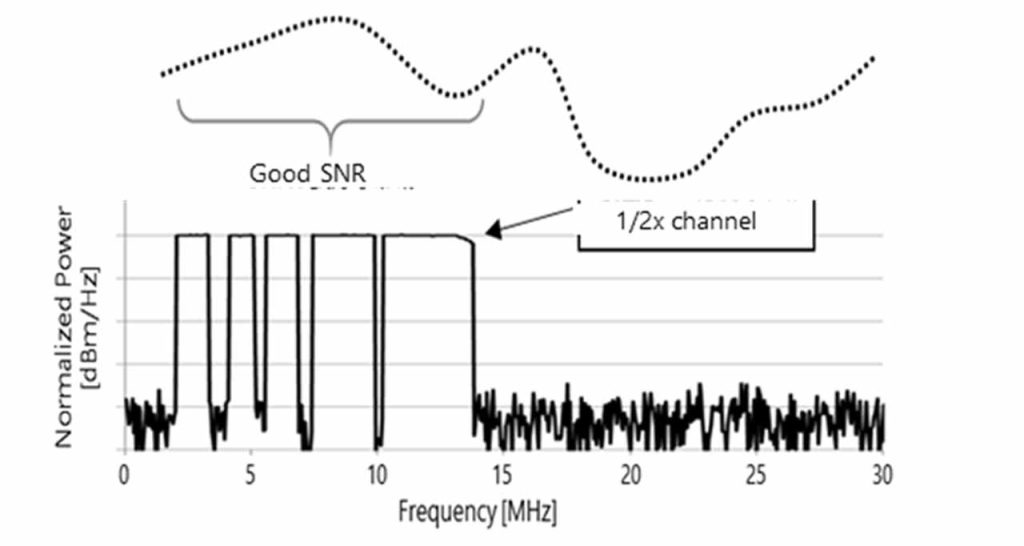

Nessum uses frequencies between 2 MHz and 28 MHz, which is allowed for powerline communication under various standards, such as CENELEC EN 50561-1. It supports different channel widths, which permits the user to trade off data throughput and range.

When narrower channels are used, the network conditions can be analyzed, and the most appropriate channel can be used. Nessum also supports the “notching” of channels to prevent interference with other transmitters using the band or to comply with regional regulations.

Nessum is standardized as IEEE 1901-2020, which specifies the medium access protocol and modulation for broadband powerline systems and an inter-services protocol for interference management.

Nessum offers several security features to prevent unauthorized access to services. The connection is wired, providing a baseline level of security. The tone map that defines the signal modulation is modified according to the transmission characteristics of the link between each node, which reduces the possibility of interception. Finally, AES-128 based link-level encryption is provisioned to each terminal node by the Nessum network master node. This can be administered at the elevator system, building or enterprise level.

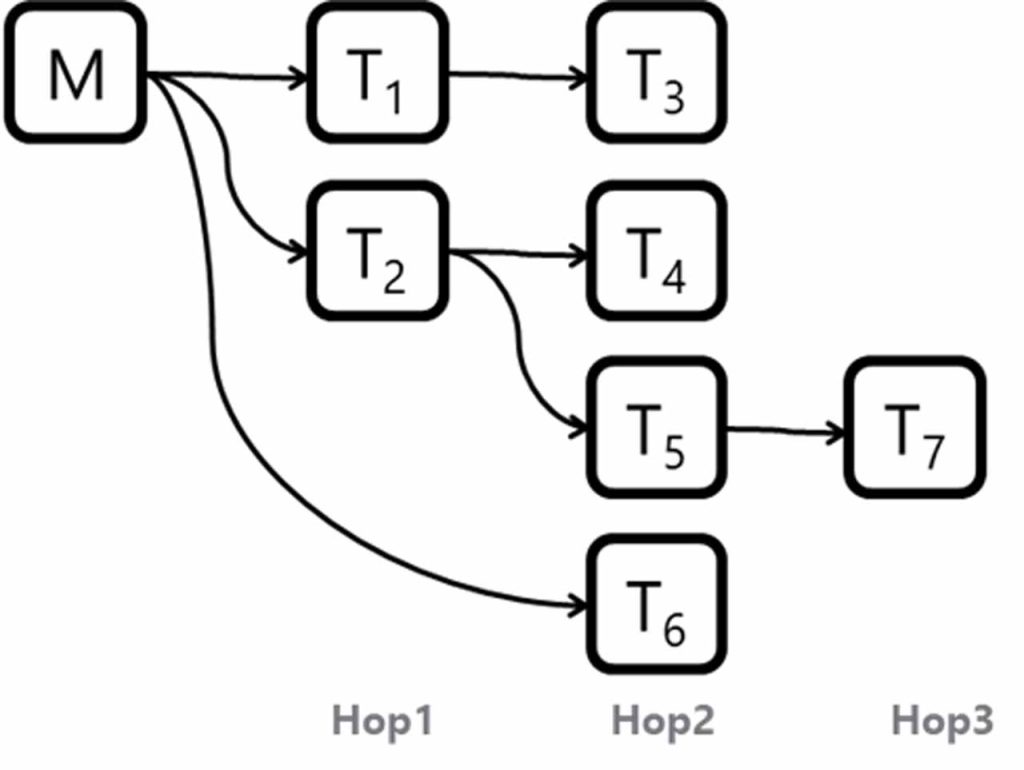

Nessum also supports ITU-T Recommendation G.9905, a robust and low-overhead multi-hop routing protocol that enables large-scale networks. The Nessum implementation supports up to 10 hops over up to 1024 nodes, which yields a maximum range of 10 Km.

In multi-hop, each device can act as a repeater. The centralized metric-based source routing (CMSR) protocol determines the best routes between devices. In the event of a device going offline and being unavailable for hopping, the network will be reconfigured automatically using the available devices, ensuring a seamless connection.

Socionext SC1320A Nessum Interface Device

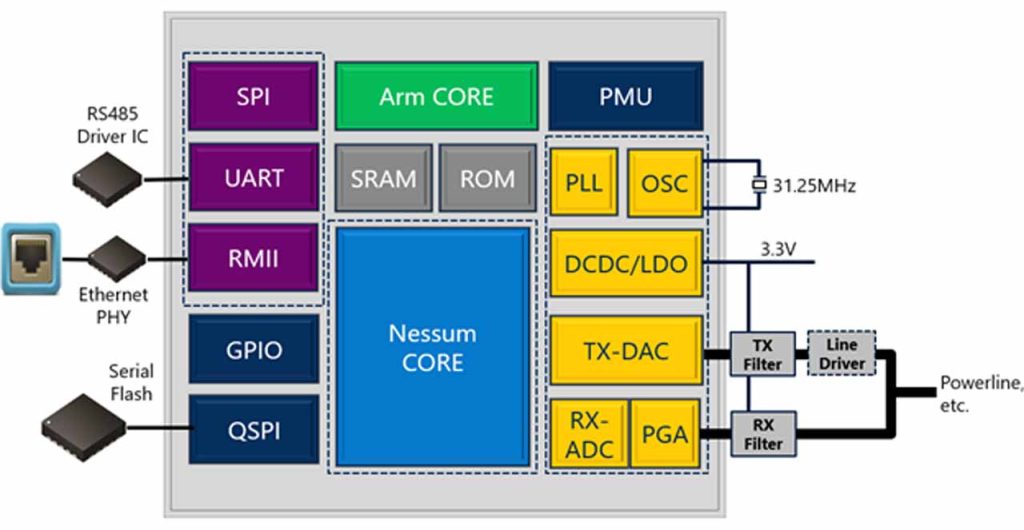

The Socionext SC1320A device has integrated Nessum medium access control (MAC) and physical (PHY) layers. It implements a bridge between Nessum and Ethernet and also allows the connection of a variety of external peripherals using industry standard interfaces such as SPI and UART and general purpose input/output. It supports a secure boot from the external serial Flash ROM via a Quad SPI interface.

It is available in a compact 7 mm-X-7 mm package, operates within the industrial temperature range and requires a single 3.3-V power supply. Power consumption is less than 200 mW.

Get more of Elevator World. Sign up for our free e-newsletter.