A look at safety systems in a modern high-rise elevator in light of 2018 Chicago incident

While the below information may be familiar to the seasoned elevator professional, it is particularly useful to laymen and those new to the industry Editor

In late 2018, an express elevator in a Chicago skyscraper was traveling down from the 95th floor to the lobby when it came to an unexpected stop away from a landing. Investigators found that one of the elevator’s seven suspension cables had broken, likely as the elevator was passing the 20th floor. The car slowed to a safe, controlled stop between the 12th and 11th floors. The six passengers inside were unhurt.

The incident immediately generated sensational media headlines, variously claiming that the elevator at 875 North Michigan Avenue (formerly the John Hancock Center) had plummeted, plunged or fallen 84 floors. It hadn’t.

Like all modern high-rise elevator systems, the building’s elevators are equipped with multiple and redundant safety systems to keep passengers safe.

The breaking of a suspension cable is an extremely rare event. In this case, the safety systems worked exactly as they were designed to work — and as required by applicable codes. This article explains in simple terms how these systems work, so people can understand why they should feel safe riding in a properly maintained elevator in one of today’s supertall buildings.

Safety History

The Greek mathematician Archimedes is generally credited with creating the first elevator-like device in the 3rd century B.C. Hoists were used mainly to lift heavy loads like building material for millennia. Elevators only became a safe, reliable means of transportation for people after 1852 — the year Elisha Graves Otis invented the elevator safety brake. His invention made the modern skyscraper possible and forever changed how we live.

An inspired piece of engineering, Otis’ safety brake kept the elevator from falling if the hoisting rope broke. If the rope went slack, the release of tension triggered the safety brake — a large leaf spring that snapped into notches cut into rails that supported the elevator on opposite sides of the elevator car.

Otis was so confident in the reliability of his device that he conducted a public demonstration in 1854 during the Exhibition of the Industry of All Nations in NYC. Standing high above the crowd on a platform lift, Otis ordered the retaining rope cut. The platform dropped a few inches; the safety brake held, halting the platform’s descent. “All safe, gentlemen, all safe,” Otis theatrically declared.

The safety systems in modern high-rise elevators are infinitely more advanced than Otis’ original safety brake, incorporating sophisticated technologies refined over generations by engineers working in areas like advanced computing, sensor technology and materials science. A good example is the elevator safety brake made of the same alloy used in jet-engine nozzles — ideal for both applications because of its high heat-resistant properties.

The Safety Chain

In describing the safety system in today’s high-rise elevators, engineers talk about a “safety chain.” It’s a metaphor that turns the familiar proverb on its head. One break in the chain, and the elevator stops until the issue is resolved. Herein lies its strength.

For instance, if a sensor detects that a door lock hasn’t engaged, the controller prevents motion of the elevator until the issue is resolved. There’s also no need to worry about the power going out. If the electricity is cut to the machine, the machine brake automatically engages, and the elevator stops. Passengers may be inconvenienced, but they’ll be safe.

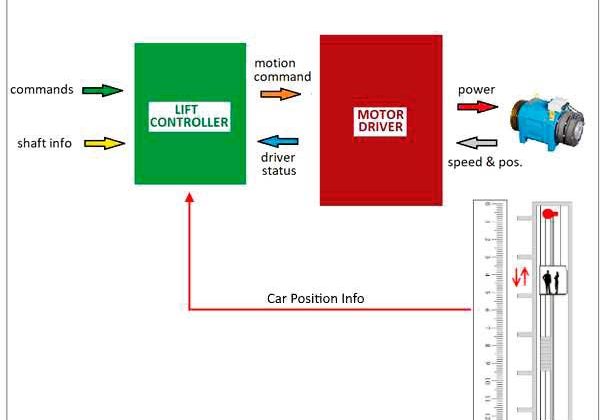

Modern elevators have two basic sets of safety components: electrical and mechanical. The electrical components include the elevator controller, sensors and software systems. The controller serves as the brains of the system. Sensors monitor safety-related functions like car speed and position, door-lock state or access panel position, and they send the data back to the controller. Software systems provide independent assessment to validate redundant sensor systems.

The mechanical components include the elevator machine itself, the machine brake, the overspeed governor, the safety brakes (also known as the car safeties) and, finally, the buffers at the bottom of the hoistway. The suspension cables themselves are also essential components of the safety system. High-rise elevators today move up and down on many cables, far more than are needed to support a fully loaded car.

Sample Scenario

Suppose an elevator exceeds its rated speed by a certain percentage: a link in the safety chain has been opened, triggering the control system to safely stop the elevator.

The Elevator Machine

In this case, the elevator’s sensors communicate the acceleration to the controller, which initially modifies current to the machine to slow the elevator. At this point, the machine brake hasn’t been applied. The machine itself is slowing the elevator. The process is similar to downshifting in an automobile with a manual transmission, instead of stepping on the brake.

Machine Brake

If modifying current to the machine doesn’t slow the elevator enough, the controller then removes all power from the machine and applies the machine brake, slowing the elevator further. The safety system is designed (per applicable codes) to bring the elevator to a controlled stop.

Governor and Car Safeties

If the elevator continues to accelerate — or “overspeed” in engineering jargon — the governor is the next component in the safety hierarchy to be activated. The governor is a speed-sensing device mounted in the machine room. It has its own pulley, moved by a steel cable (the governor rope) attached to the elevator car — meaning it moves at the same speed as the elevator. If the governor spins too fast, flyweights inside spring outward, tripping a device that grabs the governor rope.

The now-motionless governor rope pulls on the safeties — essentially emergency brakes on the car itself — and engages them.

The safeties clamp onto the hoistway rails, bringing the elevator to a safe stop. These safeties are the modern version of Otis’ safety brake.

Buffers

Located at the bottom of the hoistway, buffers can absorb and dissipate the energy of a descending elevator. In high-rise elevator systems, the buffers are hydraulic pistons that look somewhat like the hoists automobile mechanics use to raise a car so they can work on the undercarriage.

Buffers come into play if the other braking components don’t have enough time to bring the elevator to a complete stop by the time it reaches the bottom of the hoistway. They slow the car to a stop, acting like giant automotive shock absorbers.

Advances in Safety

As reliable as these safety systems are, research engineers are constantly developing new technologies that continue to improve performance. A relatively recent innovation is Programmable Electronic System in Safety-Related Applications for Lifts (PESSRAL).

With advances in programmable electronic systems, control systems have gotten even smarter. Instead of knowing only that a link in the safety chain is open, they can identify which link is open and tailor the response based on the situation. The control system’s response becomes more like how people respond behind the wheel of an automobile: sometimes, they choose to change lanes; other times, they decide to come to a complete stop.

With PESSRAL, the controller becomes smarter and acts with a customized response to an issue, instead of having only one choice available: stopping the elevator and preventing its operation.

Summary

Since Elisha Graves Otis’ inspired invention of the safety brake, the safety features on modern high-rise elevators have evolved into fully integrated systems comprising mechanical components, smart controllers and advanced electronics with multiple safety redundancies built in.

With all these measures in place, elevators provide a safe, reliable and convenient mode of transportation.

More than that, elevators have played an indispensable role in creating the connected urban world of today. According to the United Nations, 55% of the world’s population, or about 4.4. billion people, lives in cities. This figure is expected to reach nearly 70% by 2050. It is impossible to imagine this world without elevators.

Get more of Elevator World. Sign up for our free e-newsletter.