Abstract

The Indian Standards on lifts have been in existence for many years. The current series of Lift Standards, namely IS 14665 Part 1 to Part 5, was published in the years 1999 to 2001 replacing the then current standards IS 4666, IS 1860, IS 3534, and other component standards. The Indian Standards on Special Lifts, e.g., lifts for Persons with Disabilities, Hydraulic Lifts, Home Lifts, and Machine-Room-Less Lifts, etc., were added subsequently. Now, another big revision to the Lift Standards based on ISO 8100-part 1 and ISO 8100-part 2 is in the offing. But any changes or amendments to existing standards are never retrospective in nature, meaning they are applicable only to newly installed lifts. To upgrade existing lifts to new levels, especially with enhanced safety requirements within the specified time frame based on a risk assessment, the SNEL (Safety Norms for Existing Lifts) standard was prepared. This article is intended to guide users through that standard, IS 17491:2020.

Introduction

The vertical-transportation (VT) industry in India has been largely regulated by the State Lift Act & Rules. As of now, there are 11 states and one union territory that have enacted their own Lift Act and framed rules thereunder. In addition, the Bureau of Indian Standards (BIS) published several Indian Standards on Lifts and Escalators more than 30 years ago.

Typically, the Indian Standards are voluntary in nature. A few standards are made mandatory for the BIS mark to protect consumer health and safety, and a few others are covered under the compulsory registration scheme. However, some states, e.g., Kerala, Tami Nadu, Karnataka, Jharkhand and Haryana, have incorporated clauses in their respective Lift Act and Lift Rules making compliance to the relevant latest Indian Standards on the Lifts and Escalators compulsory. Lifts and escalators are regulated through the National Building Code of India, as well. New Indian Standard IS 17491:2020 was released by BIS, and this article will guide users on enhanced safety features and upgrades required for old lifts running in buildings.

Background

More than 500,000 lifts are in use today in India, and almost 50% of those were installed more than 25 years ago. Existing lifts were installed to the safety level appropriate at that time. This level is less than what is required in today’s state-of-the-art lifts, ensuring enhanced safety requirements for passengers, users and mechanics.

New technologies and social expectations have led to today’s modern lifts. This has led to enhanced user safety and reduced accidents. However, users and authorized persons expect a common acceptable level of safety. In addition, it is important to provide a safe means of VT for disabled and elderly persons without supervision. Lift attendants, and in many cases building caretakers, are not so common anymore, so it is important that relevant safety features for the rescue of trapped persons should be provided.

Furthermore, the lifecycle of a lift is longer than that of most other transportation systems and building equipment, which therefore means that lift design, performance and safety can fall behind modern technologies. If existing lifts are not upgraded to new standard requirements, users may not get the advantages of enhanced safety features.

Benefits Apart From Enhanced Safety

Reduced Energy Consumption

Energy efficiency is required of all building equipment. Reducing energy consumption has become an important factor in the fight against global warming and reducing CO2 emissions. Since the building stock is responsible for roughly half the emissions of CO2, not only through heating and direct emissions, but also through indirect emissions from the electricity consumed by systems such as heating and cooling and running lifts and escalators, it is seen that new technology controls have a positive effect in terms of energy savings and on the safety level of the lift from a user’s perspective. For example, dealing with stopping/leveling accuracies, one measure can be to replace or upgrade the drive system, e.g., “single speed, two speed drive or ACVV drive” to a “variable frequency drive system (ACVF).” This enhances the safety level of the lift, while at the same time brings energy savings.

| Sr # | IS17491:2020 Risk Clause No. | Risk Description | Category |

| 1 | 5.1 | Presence of Harmful Materials | High |

| 2 | 5.2.1 | No or Limited Accessibility for Persons with Disabilities | Medium |

| 3 | 5.2.2 | Drive System with Bad Stopping/Levelling Accuracy | High |

| 4 | 5.3 | No or Inadequate Vandal Resistance | Medium |

| 5 | 5.4 | No or Inadequate Control Functions in Case of Fire | Medium |

| 6 | 5.5.1 | Well Enclosures with Perforate Walls | High |

| 7 | 5.5.2 | Partially Enclosed Well with too low enclosure | High |

| 8 | 5.5.3 | Inadequate Locking Devices on Access Doors to well and pit | High |

| 9 | 5.5.4 | Inadequate Vertical Surface below Landing Door Sills | High |

| 10 | 5.5.5 | Counterweight without Safety Gear in case of Accessible Spaces below Well | Low |

| 11 | 5.5.6 | No or Inadequate Partition for Counterweight | Low |

| 12 | 5.6.1 | No or Inadequate Pit Screen for Several Lifts in the Same Well | High |

| 13 | 5.6.2 | No or Inadequate Partition for Several Lifts in the Same Well | High |

| 14 | 5.7 | Insufficient Safety Spaces in Headroom and Pit | High |

| 15 | 5.8 | No or Inadequate Stopping Devices in the Pit or in the Pulley Room | High |

| 16 | 5.9 | No or Inadequate Lighting of the Well | High |

| 17 | 5.10.1 | No or Unsafe Means of Access to Machine and Pulley Room | High |

| 18 | 5.10.2 | Slippery Floor in Machine or Pulley | Low |

| 19 | 5.10.3 | Insufficient Clearances in Machine Room | Medium |

| 20 | 5.10.4 | No or Inadequate Protection on Different Levels in Machine | High |

| 21 | 5.10.5 | Inadequate Lighting in Machine or Pulley | High |

| 22 | 5.10.6 | Inadequate Means of Handling Equipment | Medium |

| 23 | 5.11.1 | Perforate Landing Doors and Car Doors | High |

| 24 | 5.11.2 | Inadequate Design of Landing Door Fixings | High |

| 25 | 5.11.3 | Inadequate Glass in Doors | High |

| 26 | 5.11.4 | No or Inadequate Lighting on Landing Doors | Medium |

| 27 | 5.11.5 | No or Inadequate Protective Devices on Power Operated Doors | High |

| 28 | 5.11.6 | Unsafe Locking Device of Landing Door | High |

| 29 | 5.11.7 | Unlocking of Landing Door without a Special Tool | High |

| 30 | 5.11.8 | No Automatic Closing Device on Sliding Doors | High |

| 31 | 5.11.9 | Inadequate Link between Panels of Landing Doors | High |

| 32 | 5.11.10 | Inadequate Fire Resistance of Landing Doors | Medium |

| 33 | 5.11.11 | Car Door Moving with Open Landing Door: Hinged Landing Doors in Combination with Power Operated Horizontally Sliding Car Doors | Medium |

| 34 | 5.12.1 | Large Car Area in Relation to Rated Load | Low |

| 35 | 5.12.2 | Inadequate length of car apron: Avoidance of the risk of people falling into the well (car apron) | Medium |

| 36 | 5.12.3 | Unsafe Locking of Car Roof Trap Door | Medium |

| 37 | 5.12.4 | Insufficient Strength of Car Roof | Low |

| 38 | 5.12.5 | No or Inadequate Balustrade on Car | High |

| 39 | 5.12.6 | Insufficient Ventilation in Car | Medium |

| 40 | 5.12.7 | Inadequate Lighting in Car | Medium |

| 41 | 5.12.8 | No or Inadequate Emergency Lighting in Car | Medium |

| 42 | 5.13.1 | No or Inadequate Protection Means on Sheaves, Pulleys or Sprockets against Introduction of Objects, Bodily Injury, Ropes leaving Pulley Grooves | Medium |

| 43 | 5.13.2 | No or Inadequate Safety Gear and/or Over Speed Governor on Electric Lifts | High |

| 44 | 5.13.3 | No Protection Means against Ascending Car Over Speed on Traction Drive Lifts with Counterweight | Medium |

| 45 | 5.14 | No or Inadequate Buffers | High |

| 46 | 5.15 | No or Inadequate Final Limit Switches | Medium |

| 47 | 5.16.1 | Large Gap between Car and Wall Facing the Car Entrance | High |

| 48 | 5.16.2 | Excessive Distance between Car Door and Landing Door | High |

| 49 | 5.17 | No Redundancy in the Brake of the Lift Machine | High |

| 50 | 5.18 | No Independent Starting Contactors | High |

| 51 | 5.19 | No Lockable Main Switch | Medium |

| 52 | 5.20.1 | No Protection against Phase Reversal | High |

| 53 | 5.20.2 | No or Inadequate Inspection Control Station and Stopping Device on Car Roof | High |

| 54 | 5.20.3 | No or Inadequate Alarm Device | High |

| 55 | 5.20.4 | No or Inadequate Communication System between Machine Room/Lobby and Car (Travel Height greater than 30 m) | Medium |

| 56 | 5.20.5 | No or Inadequate Load Control on Car | Medium |

| 57 | 5.21 | Missing Notices, Markings and Operating Instructions | Medium |

| 58 | 5.22 | No or Inadequate Automatic Emergency Rescue Operation | High |

Improved Accessibility (Access to the Building)

People are living longer. Senior citizens, along with people with disabilities and impaired mobility, require access and expect safety without the need of assistance. Accessible lifts are fundamental in allowing people to meet and interact – which is important for maintaining social relationships and quality of life, and can help to increase the lifespan of senior citizens. By integration of accessibility standard IS 15330:2020 and IS 17491:2020 “SNEL,” we can easily help achieve this goal.

Reduced Risk of Liability Issues

The degree of liability depends on state legislation and the specific facts of each case. However, one should understand that many parties (lift company, maintenance company, lift owner, third party, government, etc.) may be affected when it comes to an accident, especially one resulting from the SNEL-identified risks and caused by insufficient safety measurements applied to lifts. If the SNEL standard is followed, then the risk and liability may be reduced.

Identified Safety Risks and Priorities

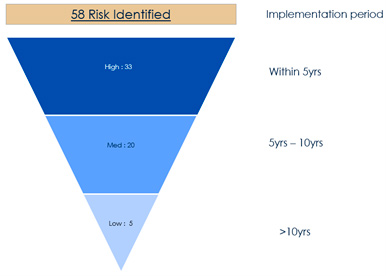

This Indian standard has identified 58 risks (see Table 1) that may exist on existing or old lifts. Out of these, 33 are high priority, 20 are medium priority and five are low priority. There are no extreme priority risks identified. Risk profiles with priority levels has been given in Annex A of the IS 17491:2020.

Applicable state authorities will determine their own program of implementation in a reasonable and practical way based on the level of risk and economic considerations. For example, priority extreme required immediate action, high priority (short-term) within five years, medium priority within 10 years and low priority (long-term) together with the modernization of related component or lift.

Some Important “High Category” Risks Explained

Picture illustrations source: European Lift Association (ELA) SNEL Brochure (ela-aisbl.org)

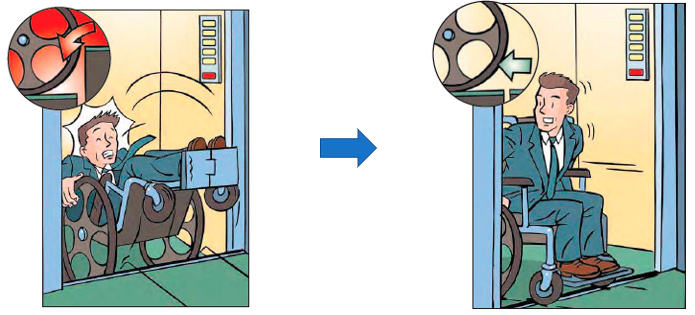

Drive System With Bad Stopping/Leveling Accuracy: (IS 17491 Clause #5.2.2)

- Risk — Poor leveling accuracy (level difference between car and landing door sills) can make people trip and fall and even hit their head on the wall of the lobby or inside the lift. In case of a wheelchair user, there is a risk of falling backwards getting in or out of the lift, causing serious injury.

- Mitigation — New technology control systems use ACVF drives and re-leveling devices to ensure that the lift is always level and re-levels. The stopping accuracy of the car shall be ± 10 mm; a leveling accuracy of ± 20 mm needs to be maintained. If, during, e.g., loading and unloading phases, the value of 20 mm is exceeded, it needs to be corrected.

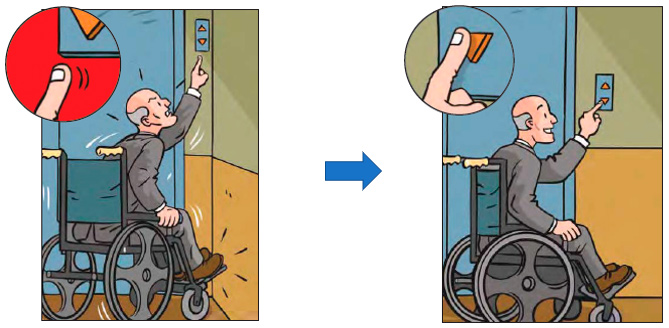

No or Limited Accessibility for Persons With Disabilities: (IS 17491 Clause #5.2.1)

- Risk — Older lifts were not designed for use by persons with disabilities. Small but important things, like insufficient door width or distance/height of buttons on the wall, makes the lift inaccessible for a person using a wheelchair. Some required features that were missed are floor and door status announcements, tactile or readable button indicators, good lighting conditions and general access to the lift. This situation is worse in public buildings.

- Mitigation — All lifts must be constructed or adapted so that they are accessible to ALL as defined in IS 15330:2020 or Harmonized Guidelines issued by NIUA.

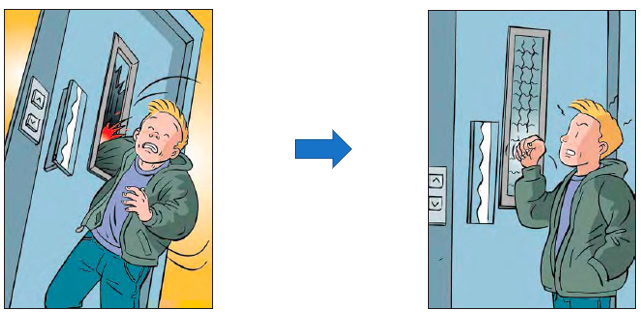

Inadequate Glass in Door: (IS 17491 Clause #5.11.3)

- Risk — If there exists a glass vision panel in a lift landing and/or car door, it must have safety or toughened glass and be sufficiently guarded, making it impossible for a person to break the glass by impact or to put through the opening a body part such as hand/head or an object. This can lead to serious injury or even death.

- Mitigation — All lifts with a glass vision panel in landing doors must be equipped with safety glass and protection grill.

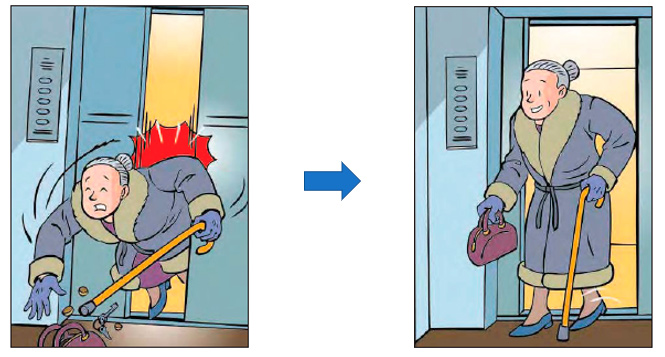

No or Inadequate Protective Devices on Power-Operated Doors: (IS 17491 Clause #5.11.5)

- Risk — When a person is entering or exiting the lift when the doors start closing, the absence of contactless protection means the fast-moving automatic doors can hit hard on the person. Elderly and disabled persons can have body parts injured by the impact or because of the subsequent fall.

- Mitigation — Power-operated doors must have an adequate protective closing device installed, detecting the presence of the person/s in the doorway and reopening the doors immediately. For this purpose, contactless sensitive multi-level light screens are required to be installed.

Inadequate Length of Car Apron and No or Inadequate Automatic Emergency Rescue Operation: (IS 17491 Clause #5.12.2 and 5.22)

- Risk — People occasionally get trapped in lifts due to power cuts or other reasons. Passengers sometimes panic and try to jump out of the stalled lift. In doing so, there exists a risk of the person falling in the hoistway below. This can happen while rescuing trapped persons, especially when a lift car has stopped above the landing level.

- Mitigation — There must be a car apron below the lift car sill of sufficient height and strength that will eliminate the risk of falling. The height of the vertical portion of the apron shall be at least 750 mm.

Also, the use of a battery-operated Automatic Rescue Device (ARD) will rescue trapped passengers safely and will park with doors open until power is resumed.

Presence of Harmful Materials (Especially Asbestos): (IS 17491 Clause #5.1)

- Risk — The lift mechanics or inspectors (and possibly users) are exposed to harmful materials due to wear, aging, repair or modernization work. Of particular concern today is asbestos, which spreads in buildings as a dust and can cause a fatal lung disease later.

- Mitigation — The building owner must eradicate asbestos and other harmful materials from the building structure or components so as to remove it completely or by fixing a special film over the asbestos surfaces and providing warning stickers indicating there is asbestos behind the film. Existing asbestos brake lining from lift machines must be replaced with asbestos-free brake lining.

Perforate Landing Doors and Car Doors: (IS 17491 Clause #5.11.1)

- Risk — Users, especially children, can put their hands through both doors, without opening them, to handover some small items or to send the lift to the desired landing by pressing car calls from outside. This can result in severe injuries, including arm amputation and even fatality.

- Mitigation — Replace all perforate-type car and/or landing doors (such as collapsible gates) with automatic-type metallic doors for buildings having height >15 m or imperforate-type doors (such as accordion-type or swing doors) for buildings having height <15 m.

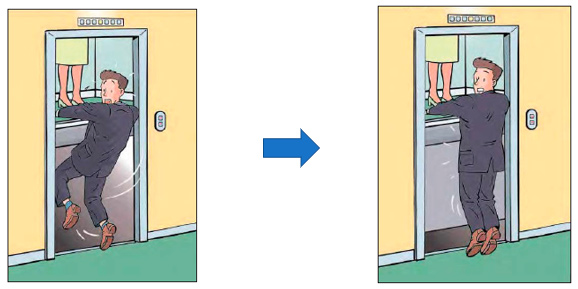

Excessive Distance Between Car Door and Landing Door: (IS 17491 Clause #5.16.2)

- Risk — Users, especially small children, can get trapped between car and landing doors as the gap between them is more than 130 mm. As both doors have closed, the lift can now move, resulting in severe injury or even fatality for the trapped person.

- Mitigation — Adequate measures, such as a box-type enclosure, to restrict this gap between car and landing doors less than 130 mm should be taken.

Conclusions

The above discussed improvements will go a long way in enhancing the safety of persons using and maintaining lifts. Of course, lift maintenance is very important, and keeping lifts in safe working condition is only possible through a well-planned and executed maintenance program. However, only a safely designed and properly installed lift can operate in safe condition with good maintenance.

Disclaimer

The above article is written in good faith to educate and make people aware of the newly published Indian Standards on lifts. The examples described here are of the nature of bird’s eye view and do not contain all the information/conditions in depth, for which users are advised to refer to the original text.

All pictures in the article are courtesy European Lift Association (ELA) SNEL Brochure (ela-aisbl.org).

Further, the views expressed are personal to the author. The author/publisher or the organization where the author may be employed shall not be held responsible for any action taken by anybody based on the information contained in the article.

Get more of Elevator World. Sign up for our free e-newsletter.