Can the industry make more money by selling elevator up time instead of service visits?

The elevator industry earns most of its living from maintenance contracts. You can presumably make more money by selling elevator up time instead of service visits. At the same time, you get better functioning elevators and happier customers.

More Visits, More Breakdowns

Most contracts stipulate an annual number of maintenance visits. From experience, it is known that more breakdowns are likely to occur with more maintenance visits. This seems like a paradox but can possibly be explained with the simple fact that a very short time is allocated for each visit, and the required maintenance often gets pushed to the next visit. If there are fewer visits, the technician will know beforehand that there is a lot to do for each. Enough time will be allocated to clean, lubricate, adjust and replace. The elevator will be put in good condition, therefore made less likely to break down.

Start by Hating Call-Outs

Consequently, the biggest savings in elevator maintenance comes when not visiting the elevator. How can this be achieved? The easiest way is to motivate technicians to dislike breakdowns. Avoid having special “fire-fighters” who only work on breakdowns, and give every service technician his or her own elevators for which he or she is fully responsible. As long as you have troubleshooters, you will have trouble. A call-out technician will just identify and fix the fault, then run off to the next problem. The elevator will never be cleaned, lubricated, adjusted or have its parts replaced preventively.

If your organization is divided into call-out and maintenance people, you will need a certain amount of persuasion and motivation to change into an organization in which each technician takes full responsibility for his or her own elevators. If there is an elevator that breaks down more than twice per year, the reason will either be due to vandalism, it being a worn-out elevator that needs to be modernized or an incompetent or unmotivated service technician. In too many cases, it is the latter. The “personal” responsibility for one’s “own” elevators was first tested by KONE in Stockholm in 1986-1988. After only a few months, a radical drop in call-outs occurred (from an average six per year to less than two). The same drastic reduction has been evidenced in all areas where the system has been applied.

Usage-Based Maintenance

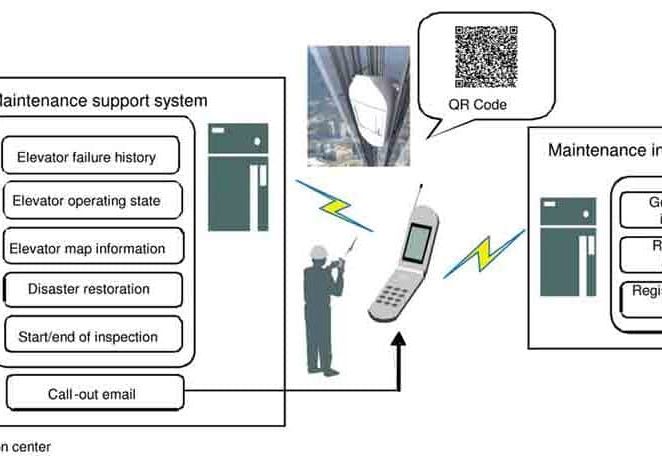

You do not service your car eight times per year, so why should elevators be different? Stop visiting by calendar time; instead, plan visits according to use. (The emergency telephone can count the number of starts and send a message when it needs maintenance.) The telephone can also pick up signals that indicate upcoming problems and send a message if anything is wrong (start failure, emergency stops due to shorts in the safety circuit, disturbance signals from controller, etc.). Most elevators work better when receiving fewer (but better) maintenance visits. Only elevators in intensive use require more than four proper maintenance visits per year. However, expect a visit to take at least two hours. Each should include cleaning all dust in the shaft and machine room, as dust kills electrical contacts. Additional visits certainly add to safety but are rarely motivated from a maintenance point of view.

Paper Visits

Elevators might get more service visits on paper than in reality. For prevention, use an input in the emergency telephone to connect a button or the inspection switch on the car. When a technician is onsite, the button can be pressed, and a ticket will be sent to the alarm receiver that logs the event. The log would positively prove that personnel have been to the elevator – something that can be useful if there were an accident or if the customer questions the response time.

Elevators might get more service visits on paper than in reality.

Verify Out-of-Order Elevators

“Elevator running upon arrival” can be the response to up to 30% of all call outs. With an emergency telephone that can command relay outputs, one can insert top and bottom calls remotely. Since you also have a microphone in the car, you can hear the door closing, the lift moving then stopping, and the door opening again. In such a case, the service call could be cancelled.

Preventive Maintenance

When a headlight bulb on your car burns out, how many do you replace? If your answer is one, then my guess is that the elevators in your service portfolio break down more than five times per year. Why is this? See it from a money perspective. The reasoning for only replacing one bulb is usually to use up the remaining lifetime of the bulb that still works. But how much do you really save? Industrially produced items have a typical lifespan of +/-2%. So, when your first lamp breaks, you can expect an average of 2% more from the second. If the cost for a bulb is EUR5 (US$6.89), the 2% savings of replacing only one bulb would equal EUR0.10 (US$0.14).

Taking the same example for an elevator, assume the up contactor reached the end of its lifetime. Since other parts would experience the same wear, it would be less effective to replace only the faulty part: if the part costs EUR50 (US$68.92), the upside is that you save up to 2% (EUR1 [US$1.38]). The downside is that you have a call-out waiting to happen. This cost is at least EUR100 (US$136.72), plus an angry customer. If the contract is full service or does not allow you to bill for call-outs, then you are cheating yourself. If you can bill the customer for the call-out and work, you are cheating the customer. After all, he or she would still need to pay for the new contactor, but the extra EUR100 (US$136.72) in call-out cost could be used to put the elevator in better condition. The customer looks at how much his or her elevator costs and hardly knows what he or she gets for the money. If you are wasting customers’ money on unnecessary call-outs, your elevator portfolio will reflect poorly.

“But We Make Money from Visits and Call-Outs.”

How often has your car broken down on the road this year? Why should elevators be different? In fact, if you see it from the customer’s point of view, every time you shut the elevator down for maintenance, the customer has an elevator out of service. If a customer is willing to pay for vehicle preventive maintenance, he or she will say the same about his or her elevators. In most cases, the customer is willing to pay more if the elevator breaks down less.

I would even argue that you do not make any profit on call-outs. First, deduct the cost for disturbing other jobs. Second, check how many are actually invoiced, and third, verify that the bills are finally paid (not just credited). Logically, you buy visit hours from your service people and resell it to the customer with a markup. You may have even put this into the contract (“X annual visits for the price of Y”). This yields a price-per-visit mentality. Therefore, fewer visits mean lower revenues.

Fewer Visits Mean Higher Profit

A reduction in the number of visits is simple to turn into money. Change the wording of the “maintenance contract” to “performance contract” and charge 10% more for this type of contract. Do not specify any number of visits, but promise a high rate of availability (for example, 99.5%). It sounds very reliable to the customer but actually allows the elevator to be out of service for almost two days per year (and few elevators would be out of service that often anyway). Put a penalty of 5% for every day of not meeting the 99.5%, and your risk is minimal. Now you can pocket the saving in maintenance cost. As an example: if you had eight visits per year before at the cost of EUR60 (US$82.65) per visit, your saving of doing four visits instead is EUR240 (US$328.36). Since you decoupled the revenues from the number of visits performed, the EUR240 (US$328.36) is sheer profit. Then, add the advantage of fewer breakdowns.

Only visit the elevator when there is a good technical reason. Every breakdown is a failure in your maintenance.

Summary

Only visit the elevator when there is a good technical reason. Every breakdown is a failure in your maintenance. Pay only for results, which means working elevators (not hours worked). Divide the elevators so technicians get their own (so blame cannot be diverted). Replace parts before they wear out. Make adjustments so tolerances are on the right side. Keep the elevator clean; this prevents a lot of trouble. Use the customer’s money to improve the elevators. Stop selling visits; sell availability instead. Have less trouble and make more money.

Get more of Elevator World. Sign up for our free e-newsletter.