Scotia Plaza

Jan 1, 2022

Elevators, Modernization

Toronto

submitted by John Egan, P. Eng., Schindler Elevator (Canada)

Original construction of Scotia Plaza finished in 1988. This site, part of an iconic, three-tower complex in the heart of Toronto’s financial district, offers 2 million ft2 to numerous world-class businesses. The original architect was WZMH, which opened its offices in Toronto in 1961. The complex includes 68 stories above ground and six below, as well as a 130-ft-tall atrium.

This site is one of the few locations globally with double-deck elevators. The 22 low-rise, mid-low-rise, mid-high-rise and high-rise Schindler elevators with new 710 and 560 machines were and remain double-deck units. Speeds were increased through the modernization in the mid/high-rise and high-rise banks. Schindler supplied and installed the original elevators and, over their 30-year service life, Schindler remained the maintenance company at all times.

Schindler was awarded this recently completed 31-elevator modernization project, building on a now 33-year partnership at this site. The project included:

- Five of the double-deck units receiving speed increases of 1400 ft/min to 1,600 ft/ min, and five from 1,200 to 1,600 ft/min, making them the fastest cars in Toronto

- Replacing machines for two high-rise service cars with Schindler 610 machines

- Replacing machines for four geared shuttle cars with HW62 machines

- Modernizing two basement traction machines

- Modernizing one hydraulic service car

The TX controllers installed for this modernization set the standard for reliability in the complex, and showcase why we believe our controller is among the best on the market. There have been no issues related to the new elevator machines, which were assembled inside the machine rooms. The property has seen a 90% reduction in equipment callbacks and an increase in equipment uptime to over 90%.

Over the course of the modernization project, the building was sold to Toronto-headquartered KingSett Capital. The Schindler team worked closely with KingSett’s representative throughout the project.

The prime elevator consultant was Solucore Inc. It is interesting to note that, at one time, there were up to four consultants involved through the peer review phase. Solucore’s guidance throughout this project was provided by founding Principal Ray Eleid.

Scotia Plaza presented several site-specific challenges. For example, the machine room floor slabs were redesigned late in the original design phase to a point where machines and significant machine parts could not be landed directly on the slabs. To facilitate the handling of large loads (machines, machine components) over decades of service, a custom system of wall-mounted monorails was designed, installed and used. Machine rooms are extremely tight in this building, adding to material removal, delivery and installation challenges through service, as well as during the modernization. To facilitate the gearless machine replacements, 17 main component pieces were assembled on-site, and special carts were designed and fabricated to spread the load across the floor slabs.

Schindler’s largest gearless machines, 710 models, were used on this project. To ensure quality factory assembly, experts were flown in from Switzerland to Toronto to train and certify the modernization mechanics to ensure factory precision performance. Continuing with the logistical challenges, to ensure material flow and fit full-scale, foam models of the main machine parts were produced so that delivery paths and assembly processes could be confirmed prior to delivery of the new machines. Some machine rooms were so tight and demanding that a single machine installation involved more than 20 hoisting picks. Once rigged, machines had as little as 2 in. of clearance to the ceiling overhead in several locations, demanding insightful rigging plans and skilled work.

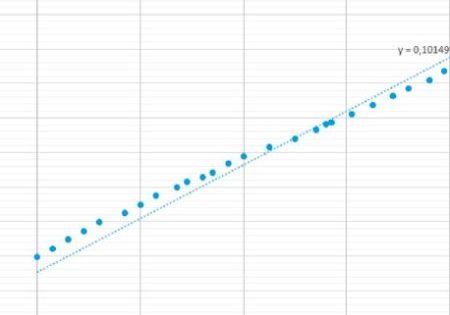

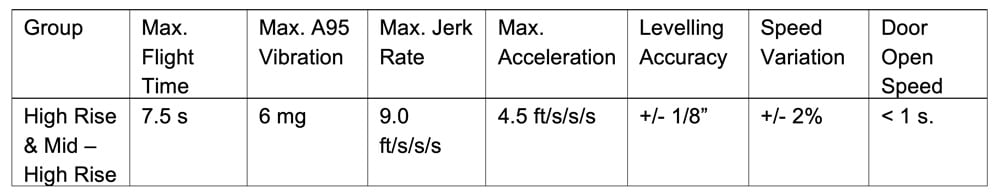

Project consultant Solucore specified best-in-class performance criteria for this iconic building as follows:

Consistent with best-in-class modernized elevator performance demands, the cab finishes, fixtures and system features on this project were nothing short of preeminent for our industry.

Single digit ride quality levels are virtually unheard of for modernizations, yet Schindler delivered. Key to delivering outstanding ride quality was the provision of Schindler R307 roller guide assemblies on the double deck elevators.

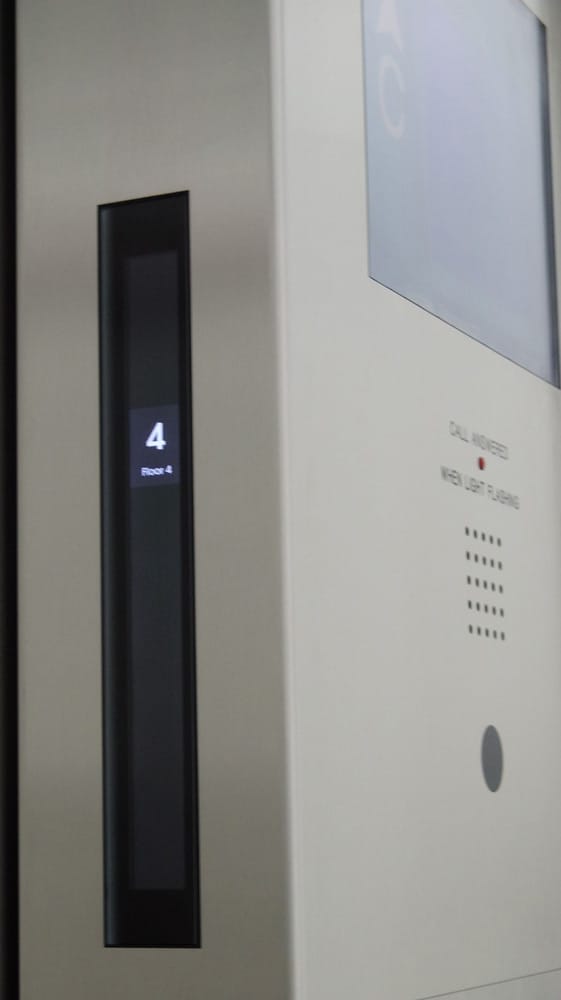

This project included — among many leading-edge features — an intricate, camera-equipped communication system that automatically facilitates selectable viewing of both the upper and lower elevator decks. In addition, the modernization called for machine bearing monitoring, a building-sway detection and elevator control system, seismic detection and the integration of Schindler’s LobbyVision system and CACF (central alarm control facility) panels across the main tower and adjoining original building at 44 King Street West. The design, supply and installation of the modernization equipment installed provided for rope sway controls, optimized hoist and compensating rope life, and, of course, Schindler’s PORT destination-dispatch system with access controls for more than 20,000 identified users.

Operationally, performance of the modernized elevators continues to excel. Callback rates on these modernized elevators are best in class, as low as 0.25 calls per car per year

The multiyear modernization of the elevators at Scotia Plaza, 40 King Street West, Toronto, Canada, was logistically and technically one of the most demanding and intricate modernization projects completed. The results of this project are nothing less than visually stunning and operationally best-in-class.

Credits

Building owner representative: KingSett Capital/Doug Gibbs

Property manager: Bentall GreenOak, General Manager Marvin Morgan, Manager of Operations John Arruda, Sr.

Elevator consultant: Solucore, Inc./Ray Eleid

Modernization contractor: Schindler Elevator Canada

Project executive: Lisa Konnry, president, Schindler Elevator Canada

Large project director: John Egan, vice president, Large Project Fulfillment

Project manager: Daniel Barros, vice president, field quality engineering

Modernization supervisor: Adrian Mahadeo

Field support engineer: David White, Sr., global field support engineer

Modernization engineer: Dan Niculae

This project would not have been possible without the tremendous contributions from multiple crews of talented and resourceful modernization technicians led by adjusters Tom McMillan and Sean Briffett.

Accolades

- Zero carbon

- LEED Platinum

- fitwel® certification (with distinction)

- Wired Certified Platinum

- Energy Star

Get more of Elevator World. Sign up for our free e-newsletter.