Selecting the Correct Rope for High-Rise/High-Speed Elevator Applications

Sep 1, 2013

by Richard L. Lindemeyer and Dr.-Ing. Andreas Franz

When choosing a wire rope for high-rise/high-speed applications, it is essential to find a rope that combines high-speed performance with features that deliver long-term cost savings, while reducing service interruptions. Traditionally, traction and extra-high-strength (EHS) traction-grade ropes with natural fiber cores were employed for these elevators in North America.

However, improved rope designs that provide many benefits over natural fiber core ropes (especially in the area of longer service life) are now available. Other characteristics that contribute to a longer-lasting rope are its construction, wire tensile strength, resistance to fatigue, increased flexibility and resistance to cross-section deformation.

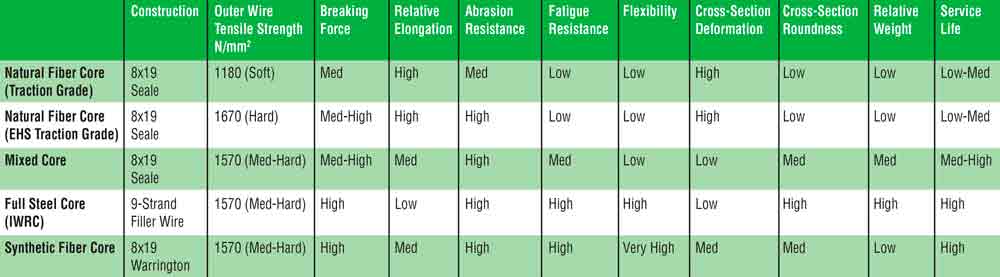

Table 1 compares traditional natural fiber core ropes with alternative constructions. A quick examination shows natural fiber core ropes offer the advantages of lower weight and acceptable values for breaking force and abrasion resistance. However, they are not strong performers in other important areas, which leads to greater elongation, lower resistance to fatigue (because of wire breaks due to bending) and increased cross-section deformation. These weaknesses result in higher long-term costs and unfavorable service life.

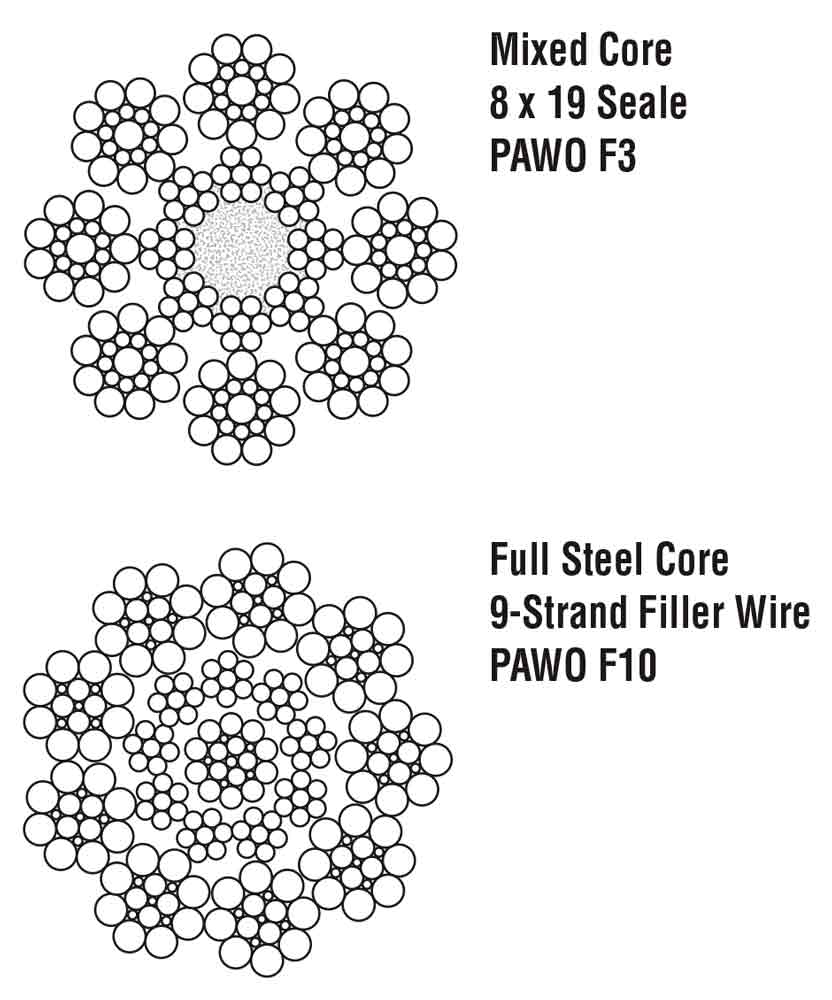

However, these newer rope designs, such as 8 X 19 construction with a mixed core using steel reinforcement of a natural fiber core and nine-strand construction with full-steel core (also called an independent wire-rope core [IWRC]) offer many advantages over natural fiber core ropes, including higher breaking force, reduced elongation, increased resistance to fatigue and less cross-section deformation. These values indicate a measurable longer service life.

Note also that the nine-strand IWRC rope offers greater flexibility and a rounder rope cross-section. If it is determined that extra-high-strength traction grade is the right choice, a rope like Gustav Wolf’s PAWO F3 (mixed core) or PAWO F10 (nine-strand IWRC) can usually be substituted for a natural fiber core rope. PAWO F10 also offers excellent resistance to elongation. However, the additional weight of a mixed core or full-steel core rope should first be analyzed to ensure that it does not exceed the equipment design criteria.

Re-roping a high-rise/high-speed installation can present some special challenges. For instance, the sheaves must be carefully checked, and re-grooved or replaced as necessary. This is because the diameter of the new ropes is greater than that of the old ropes. Failure to bring the sheave grooves into the machine manufacturer’s specified tolerances can lead to vibration, metal shavings and other problems.

Along with taking new-rope diameter into account, care must always be taken to ensure the hardness of the machine sheaves and the grade/tensile strength of the rope are compatible. Sheaves designed for a traction-grade rope may not be hard enough to accommodate EHS traction-grade ropes, and sheave damage could result. Sheave hardness can be confirmed by using a hardness tester. Sometimes the hardness is stamped directly on the sheave.

Sheave damage can be avoided by verifying the rope grade/tensile strength. If this information is unavailable, knowing the breaking force can help confirm the grade/tensile strength of the rope. Breaking force is usually indicated on the crosshead data plate. For example, if a breaking load of 17,500 lb. • 77,800 N is indicated for 1/2-in. • 12.7-mm 8 X 19 ropes, referencing the manufacturer’s catalog, data sheets or website will indicate this rope is an EHS traction-grade rope. It is important to be aware that if the original elevator machine has been replaced, the crosshead data plate may not be a reliable source of information. Also, the old rope tag may have inaccurate information on rope grade and breaking force.

The synthetic fiber (non-sisal) core rope mentioned in Table 1 is Gustav Wolf’s latest innovation, HyTrac™. It combines a high-strength synthetic core with steel wires in the outer strands. When compared to steel core ropes, the weight is 20% less, the bending performance is up to 50% higher, and the breaking force is equal. In comparison to ropes with a natural fiber core, the breaking force is higher still, at around 50% (ELEVATOR WORLD, July 2012).

When pricing ropes designed for high-rise/high-speed elevators, a very important factor to consider is the cost of the rope – not just the purchase price, but the long-term costs. Most rope replacement is performed under a maintenance contract with a flat fee. Excessive service calls for rope shortening not only cut into a company’s profits, they also create a dissatisfied customer when elevators are out of service for work that would be unnecessary had rope with less elongation and a longer service life been installed. Installing a higher-performance mixed core (PAWO F3) or nine-strand steel core (PAWO F10) rope is definitely in a company’s financial interest.

It is important to note that while certain designs offer inherently longer service life, it is essential that all hoist ropes be treated to a regular program of rope tensioning and lubrication. (Governor ropes should never be re-lubricated.) Rope tensioning can be performed with a Micelect® rope-tensioning system (RTS). An RTS allows a single technician to quickly and accurately equalize the tension of up to 12 ropes. A rope treatment/lubricant such as DrakaLube® helps mitigate the bending stress and high groove pressures found in high-rise/high-speed applications. A newly introduced automatic rope oiler, the Draka Acculube™, provides automatic, consistent and continuous lubrication for these ropes. The Gustav Wolf catalog download mentioned above also contains suggestions for a regular maintenance regimen.

In conclusion, installing mixed core (such as PAWO F3 8×19 Seale) or full-steel core (like PAWO F10 nine-strand Filler Wire) rope on high-rise/high-speed elevator re-roping or new-installation projects is to the advantage of both contractors and their customers.

Get more of Elevator World. Sign up for our free e-newsletter.