Servicing of Hydraulic Elevators after Flooding

Apr 1, 2016

Flooding of machine rooms and elevator systems as a result of natural calamity or manmade problems is not uncommon. Every year, changing weather patterns and erratic climate cause billions of U.S. dollars in damages, putting the vertical-transportation systems out of operation for days or weeks. As we will be confronted with further climate change, flooding and erratic weather patterns look to occur more often in the future.

Starting the elevator system in the aftermath of flooding is not an easy task. Troubleshooting technicians are mostly confronted with logistical and technical problems. Compounding those with time constraints and/or lack of knowhow often results in a running system that is somehow made to start but fails once again as critical components were neither inspected nor serviced properly before operation resumption.

Learning Objectives

After reading this article, you should have learned:

♦ Understanding the severity of problems before putting a hydraulic elevator back into operation in the aftermath of flooding

♦ Documentation of standard operating procedures to be followed and the importance of putting them in place in case of flooding-related problems

♦ The dos and don’ts in dealing with servicing of hydraulic elevators when flooding happens

♦ Prioritizing servicing and maintenance work by focusing on essential work

The effects of flooding on various components of a hydraulic elevator

While a natural calamity cannot be controlled or influenced, its fallouts and aftereffects should be prevented as much as possible. Knowing and having documentation of standard operating procedures available after the disaster would help a lot in bringing the elevator system back into reliable operation as soon as possible. The focus in this article would be on hydraulic elevators and especially hydraulic power units.

Assessment

It is important to assess the severity of the flooding and how long and how many of the lift components have been exposed to water. Practically all components of the hydraulic power unit can be affected. Hydraulic elevators are very easy to maintain and service, as they have fewer components, are simple by design and have easily available spare parts. Thus, getting them back in operation would be relatively easy and quick, provided the inspection and servicing is done professionally. In case water has entered the tank and mixed itself with oil, the power unit and elevator should not be started to prevent the complete hydraulic circuit from getting contaminated.

Contamination

The fear of water coming in contact with the hydraulic power unit is mostly unidirectional. Damage to components due to rusting and short-circuit of the electrical circuit is the major fear. What tends to often be overlooked is the contamination of the hydraulic oil. ISO 4406:1999 provides guidelines for defining the level of contamination present in a fluid sample (in terms of an International Organization for Standardization [ISO] rating) and is the most widely used international standard for representing oil contamination. In normal cases, oil is decontaminated using onsite portable oil filtration units without causing any major downtime. However, this only helps when water has not mixed with oil and oil composition has not changed. Floodwater brings lots of sludge, waste and fine particles, which get mixed with the hydraulic oil if the tank is submerged. Once contaminated, the hydraulic oil is more or less unusable, as using a specialized process of separating the water from the oil would not be commercially viable considering the amount of oil the tank holds.

If the hydraulic power unit is operated with such contaminated oil, it can cause permanent damage to sensitive oil seals and critical sealing surfaces and components, mainly in the control valve, cylinder and pump. It should be noted that hydraulic flow control valves (especially with pilot valve adjustments) have very fine orifices manufactured using high-precision machines with critical tolerances. The fine contamination causes the critical components to fail, then the effect of oxidation and rusting happen gradually.

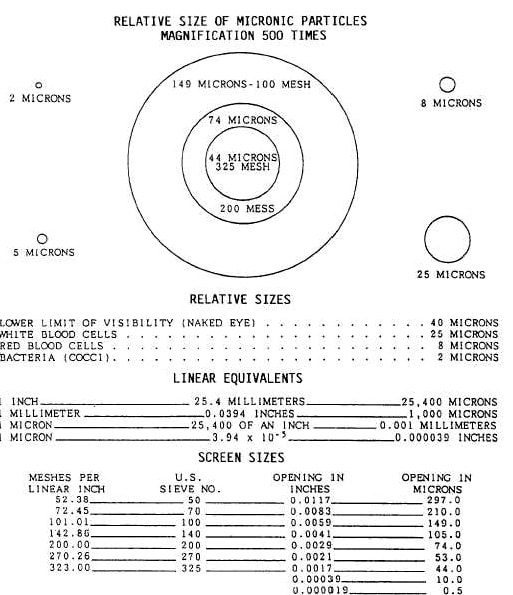

Impurities present in contaminated oil are not always visible to the human eye. A human hair visible to an eye has an approximate diameter of 75 μm. Fine contamination present in hydraulic oil ranges from 5-15 μm, whereas, generally, a human eye cannot see particles smaller than 50 μm.

Machine Room

The machine room of a hydraulic elevator is usually located in the basement. In the case of a machine-room-less (MRL) system, it may be in the pit. One of the first components that comes in contact with water is the tank of the hydraulic power unit. Accumulated water can stay in the machine room or pit for days. The tank containing the hydraulic fluid is usually made of sheet metal, which is prone to rusting once exposed to water or moisture for a long period of time.

Typically, a tank is coated with an anti-rust coating and painted/powder coated during the manufacturing processes. However, depending on the quality of this process and the tank’s age, oxidation may start sooner or later. The inside surface of the tank where the paint has been peeled off over a period of time does not rust rapidly, as it is covered with oil. However, once this comes in contact with water, the rusting process is accelerated. Oxidation releases fine particles in the hydraulic system which tend to remain in the circuit unless the system is thoroughly flushed. Critical areas are welded joints and threaded holes for fasteners.

Pump

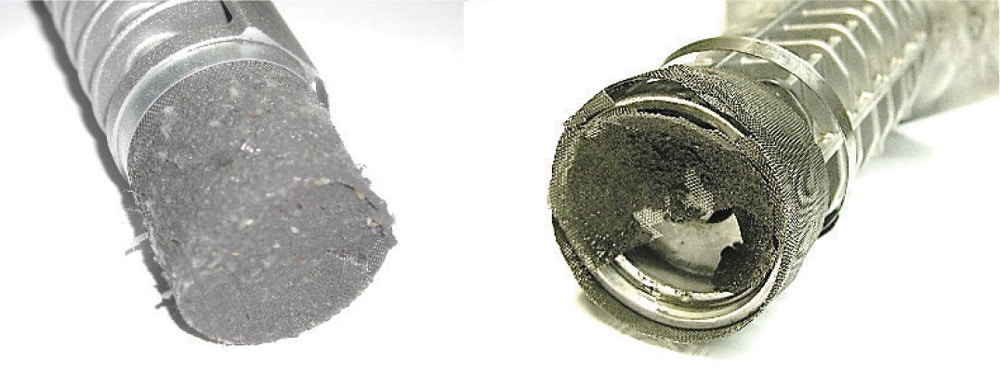

Apart from particle-based contamination, sludge carried by flooded water may get deposited in the tank and eventually be sucked out by the pump. This sticky material, together with contamination, may not only block the filter of the pump (which can create negative pressure if not cleaned properly), but also cause damage to the finely machined screws of the screw pump. Over time, the filter and fixing clip might even break or jam due to oxidation.

As submersible screw pumps are designed to operate in oil, the material used for screws can rapidly oxidize once it comes in contact with water. The screws (two idlers and one rotor) are grinded to a fine finish and manufactured with tight tolerances. Any wear and tear due to contamination results in leakages and drops volumetric efficiency. Worn-out pumps can be louder and may result in vibration, pulsation and increase in oil temperature. Thoroughly cleaning the pumps should not be forgotten. If the oxidation is severe, changing the pump is a good option. Pump bearings that have stayed under water for a few days should be replaced, as cleaning them is very difficult.

Motor

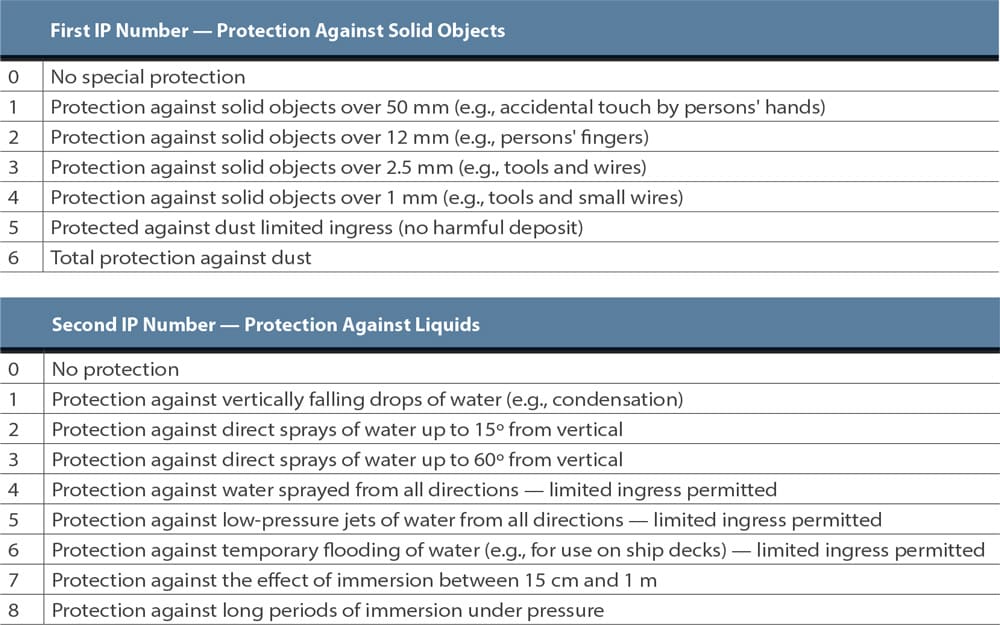

Submersible motors used in hydraulic power units are not automatically protected against water just because they are submersible. Oil-submersible motors are designed to operate under oil, not water. External motors are coupled with the submersible screw pump with a bell housing and coupling. The bell housing, which is generally made of cast iron or steel, houses the coupling, which connects the shaft of the International Electrotechnical Commission (IEC) motor and pump. It is advised to check that the coupling and bell housing are free of dirt deposits. If not, coupling wear and tear can accelerate, making the power unit noisy, especially if the shafts of the pump and motor do not rotate freely. In the case of an external IEC motor, the Ingress Protection (IP) class of the motor and exposure of the motor to water are to be considered.

Motors are rated by IP class and have a number indicating protection ratings against solid objects and liquids. The IP rating normally has two numbers, wherein the first number indicates the protection from solid objects or materials, and the second number shows the protection from liquids (water). A third (commonly omitted) number is protection against mechanical impacts.

Control Valve

The most critical component of the complete power unit is the control valve. A valve with a good design always has self-cleaning filters to protect itself from any contamination to a reasonable extent. Even if a control valve is made up of mostly nonferrous material, it may not be 100% immune to water or rusting.

To ensure longer life, frequently used pilot adjustments are often made out of mild steel, a ferrous metal. A quality product would normally have such components having a galvanized coating to ensure long life, which may offer some level of oxidation resistance within permissible limits. Inspection of the entire control valve, especially to ensure that the filters are not clogged and that sensitive adjustments are free of rust, should be done. The valve manufacturer should be consulted to know more about the effects on O-rings used in the valve with an oil/water mixture. As the O-rings are pretty easy to change and very inexpensive, changing them is highly recommended to prevent any unforeseen problems.

Any control valve is electrically operated, and proper care should be taken to ensure that the connection cables of the coil and solenoid valve are in proper condition. Depending on the manufacturer’s specification, the IP class of the coils gives an idea on the operational safety of them once they have come in contact with water.

Accessories used with the control valve like hand pumps and ball valves need cleaning and inspection, as well, because subassemblies of such accessories are often made up of mild steel. A common mistake would be to operate the elevator by pumping it with a hand pump with contaminated oil. Doing this would contaminate the complete circuit. Using an appropriate filter at the hand-pump suction port is very important and always advisable.

Lift Controller

The lift controller is usually found in the machine room near the power unit, normally mounted on the wall. However, in case of complete flooding of the basement, the operational capabilities of the elevator might itself be endangered. Controllers that have been submerged in water can seldom be reused. Those that have remained above water should be inspected by the lift-controller manufacturer or a certified elevator electrician before putting them into operation.

Also relevant is the visual inspection of the electrical terminal box, normally situated on the power unit. The unit should not be powered on until everything is dry, thereby reducing the risk of short-circuit.

Hydraulic Cylinder

A cylinder and piston set is mostly made from St-52 structural steel and is prone to rusting when exposed to moisture for long durations. A hydraulic piston is a finely polished component manufactured to high machining tolerance (up to one hundredth of a millimeter). Equally intricate is the design of the cylinder head where the oil seals are located. Wipers are used in the cylinder head to keep the dirt and contamination from entering the cylinder when the piston slides in and out.

A ram-type piston comes in contact with hydraulic oil when it moves in and out of the cylinder. Thus, the piston has a thin film of oil on its surface, which not only provides lubrication, but also helps protect the piston surface from oxidation. However, when the piston surface is exposed for prolonged durations to moisture — especially when the elevator is not in operation and the piston surface is out of the cylinder tube — there is a chance oxidation may start. This is why certain marine applications have chrome-plated piston surfaces to provide an extra layer of protection against rusting. A practical method against oxidation is to call the elevator to the lowest floor after a certain waiting time. In this way, the piston remains inside the cylinder and in oil most of the time.

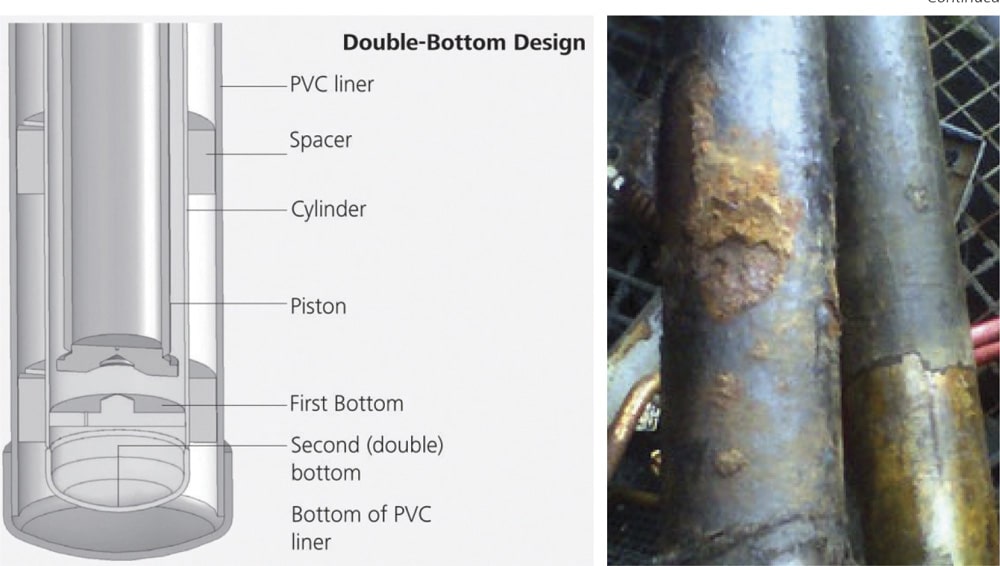

Inspection and servicing of hole-type cylinders (buried in the ground) could be more complicated than their hole-less counterparts. This is due to the fact that the condition of the buried cylinder cannot easily be optically inspected. If unnoticed, the rusting may eventually lead to busting of the tube in the long run. To prevent this, the hole-type cylinder is usually placed in a PVC tube so that it doesn’t come in contact with ground moisture.

As can be seen in Figure 5, a buried (hole-type) cylinder has a double-bottom base. The cylinder is enclosed inside a PVC tube, which is distanced from the PVC liner with spacers. The double-bottom base (with a PVC bottom layer) provides the extra protection layer against ground-based moisture and prevents rusting.

For the water to enter inside the non-hole-type cylinder, the water level has to be reasonably high in the elevator shaft so as to submerge the cylinder head completely (an extreme case). The condition of the cylinder head, oil seals, piston surface and cylinder tube should be inspected for any damage due to rusting or contamination before putting it into operation.

Guide Rails

The alignment of the guide rails and proper guiding of the guide shoes or rollers is essential for the smooth traveling of the cabin/car frame. In the event of flooding, the pit of the elevator shaft could be submerged in water, affecting the car frame if the cabin happened to be on the ground floor. Therefore, safety brakes on the car frame that trigger in case of overspeed need proper inspection before allowing the elevator to go into operation. Additionally, the guide rails should be properly greased and the condition of the shoes/rollers checked to guarantee trouble-free operation.

Piping and Rupture Valve

Hose pipe or metal pipes connect the power unit to the hydraulic cylinder. Piping may include bends, T-connectors, other fittings and different adapters, depending on the application. None of the above (especially metal pipes and fittings) are made of stainless steel and, if exposed to moisture, risks rusting. The rupture valve (often referred to as the “parachute valve”) is a safety component and usually mounted directly on the hydraulic cylinder. It is mostly made up of ferrous metal, not aluminum. Sometimes, cylinder manufacturers integrate the pipe rupture valve inside the cylinder itself. Inspection of this safety component, together with piping, is an absolute must to guarantee its working (in the event of pipe rupture). Rusting may prevent the safety valve from working or partially influence its operation, which can go unnoticed until onsite inspection is made. The rupture valve is an inexpensive safety component; replacement costs are negligible with respect to elevator safety.

Conclusion

A natural calamity cannot be influenced, but its damage can be minimized. Hydraulic elevators are simple to service and maintain, as they have many fewer parts than other types. These parts are inexpensive and readily available in the market should replacement be necessary. The technology is not patented. Qualified elevator technicians can maintain and service the systems very easily following these steps:

- Place the power unit on the first floor in areas more likely to be flooded.

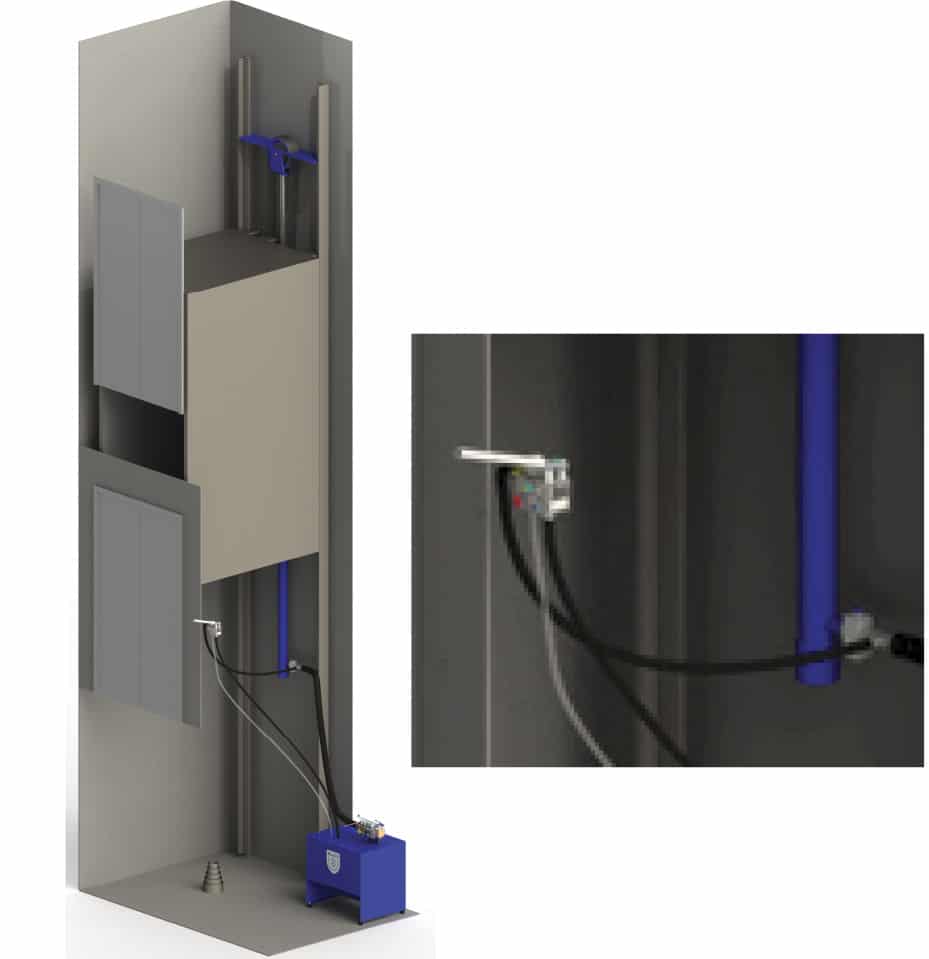

- In the case of an MRL installation or power unit located away from the access area, an MRL-H rescue unit should be used. This small unit acts like a remote control for performing rescue operations. It can be positioned beside the landing door for easy access. Emergency rescue operations like manually lowering the cabin, pumping the cabin up in case of flooding, closing the hydraulic line, etc. can be easily performed without accessing the machine room or power unit where the valve is located.

- Thorough inspections of the site and hydraulic components, including the valve and power unit, should be performed before putting the system back into operation.

- Keep in mind that contamination causes more immediate harm than water.

- The urgency of putting the hydraulic elevator system back into operation in the aftermath of flooding is understandable. At times, it is badly needed. However, doing this should not compromise the operational safety of the system, which may fail and cause more harm.

Learning-Reinforcement Questions

Use the below learning-reinforcement questions to study for the Continuing Education Assessment Exam available online at www.elevatorbooks.com or on p. 115 of this issue.

♦ What is the most important thing to ascertain before deciding the course of action when servicing a hydraulic elevator after flooding?

♦ What causes the most harm if the hydraulic elevator is put into operation without proper checks?

♦ How is the damage assessment done on the first site visit in the aftermath of flooding?

♦ Which emergency-rescue options can be provided for MRL installations, which are likely to get affected by flooding?

♦ What is the order in which one should inspect components of a hydraulic elevator after a flood?

Figure 1: Comparisons of hydraulic oil mixed with water

Figure 2: Contamination particle sizes reference

Figure 3: Clogging of pump filters

Figure 4: Section view of a submersible screw pump

Figure 5: Double-bottom hole-type cylinder in PVC sleeve to prevent ground moisture from coming in contact with cylinder (picture source: Schindler and Delta Elevator Co. Ltd.)

Figure 6: Emergency rescue using an MRL-H rescue unit

Table 1

Get more of Elevator World. Sign up for our free e-newsletter.