Determining what leads to lost energy.

by Ali Razmavar and Amir Bahram Daraei

One of the most challenging parts of calculating the power required for a traction elevator is determining the efficiency of the elevator shaft or the amount of energy lost in the movement of the car. This issue is more noticeable in elevator suspension ratio 2:1 due to the larger number of pulleys, so elevator manufacturers may mislead to choose the correct motor power. Also, most of the calculation of elevator shaft efficiency requires experimental tests and complex calculations.

For elevator shaft efficiency, the values provided by the leading motor manufacturers are usually between 60% and 86%; the exact determination of this number depends entirely on the type of elevator and the arrangement of parts inside the well. This means that some projects may need to consider the motor power 60% more than ordinary calculated power. In this article, which is the detail of the main article of a famous motor company regarding the experimental estimation of the amount of elevator shaft efficiency, we explain the effective factors and calculations of elevator shaft efficiency in different installation conditions.

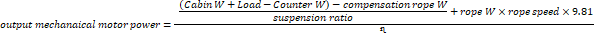

At the beginning of the discussion, the formula for calculating the required power of the motor is presented:

Calculate the required motor power:

ᶯ Total system efficiency (including gearbox losses and elevator shaft losses):

ᶯ = ᶯA * ᶯAnl

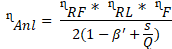

This efficiency includes ᶯA losses in the gearbox (in gearless motor it is 1) and ᶯAnl efficiency of the elevator shaft. The ᶯA efficiency, which is the gearbox efficiency (in gearbox motors) is extracted from the gearbox technical specifications table, and the elevator shaft efficiency is a variable that is completely dependent on the arrangement inside the elevator shaft; the following formula is:

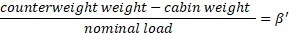

ᶯRF is efficiency of pulleys fixed to the well; efficiency is ᶯRL of movable pulleys mounted on the cabin and counterweight; ᶯF is efficiency of the guide rails of the cabin and counterweight; s is the rope weight, and Q is the nominal load of the elevator. Also, ![]() is the percent balanced (usually 0.5), which is as follows:

is the percent balanced (usually 0.5), which is as follows:

- Note 1: The ratio (cabin weight)/(rated load) affects the elevator shaft efficiency. By increasing this ratio (cabin weight to rated load), the efficiency of the elevator shaft decreases (system losses increase). So, in section B, lower value ᶯF is for the heavy cabin, and higher value ᶯF is for the light cabin.

- Note 2: The ratio (rope weight)/(rated load), which we consider 0.05 in the following calculations, show this ratio is significantly different from 0.05. A coefficient is presented in Section D to consider this change.

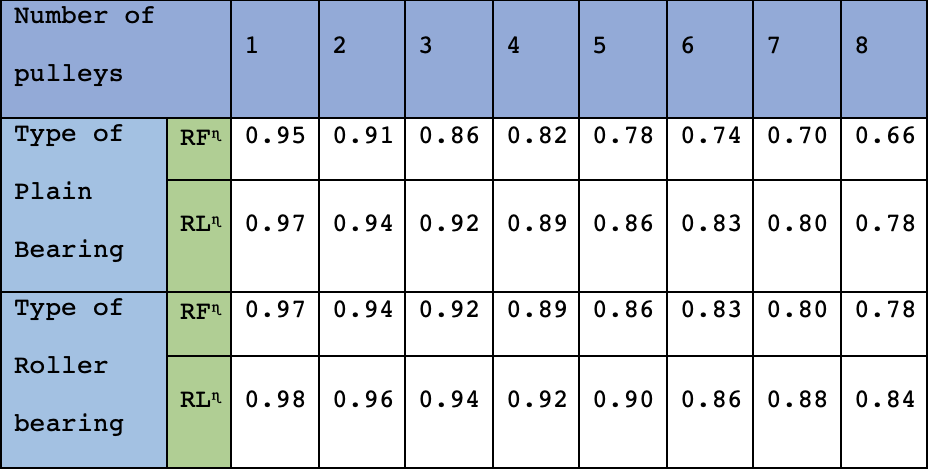

A: Efficiency for Moving and Fixed Pulleys ᶯRL and ᶯRF:

The amount of losses in pulleys depends on the type of bearings used and the installation of the pulley. Fixed pulleys (installed in the well or machine room) and movable pulleys (installed on the cabin and counterweight) are considered by the ᶯRL and ᶯRF, respectively. It is clear that the losses in fixed pulleys are more than in movable pulleys. Also, the losses in pulleys with roller bearings are less.

B: Efficiency of Guide Rails:

The losses due to guide shoes and roller of the cabin and the counterweight have a great impact on the overall efficiency. This parameter depends on several factors, including:

- Car weight

- Type of suspension

- Type and material of shoes

- How the load is distributive in the cabin

- Accuracy of assembly, installation and lubrication of guide rails

In elevators with asymmetric suspension of non-vertical cables and unbalanced load distribution, the forces exerted on the guide rails are high, which is a very strong ᶯF effect (especially L-type car frames), but here (due to the complexity of the calculations) it is better to not consider the effect of these forces and to not consider additional losses. The friction coefficient for the shoes can depend on the type of shoe and rails, material and type of lubrication.

The value given by the following calculations and experimental tests depends on the normal operation of the system and the distribution of normal load in the cabin (not L-type car frame), and the good accuracy of installation on guide rails. As we said before, the lower efficiency is related to the heavier cabin, and the higher efficiency is related to the lighter cabin:

(For slide shoes)

ᶯF= 0.9 …0.95

(For roller shoes)

ᶯF= 0.93 …0.98

As a general rule, the average of experimental data can be considered:

(For slide shoes)

ᶯF= 0.93

(For roller shoes)

ᶯF= 0.95 ᶯ

It should be noted that in L-type car frames, due to high rail friction (high losses), this coefficient is much lower, which is very effective in choosing the motor power, so in these elevators, the motors’ power must be more than elevators with routine suspension.

Based on the above data, the exact (lost) power required by the system can be accurately obtained for the installed equipment. However, these coefficients are different for high-speed elevators and high-rise buildings.

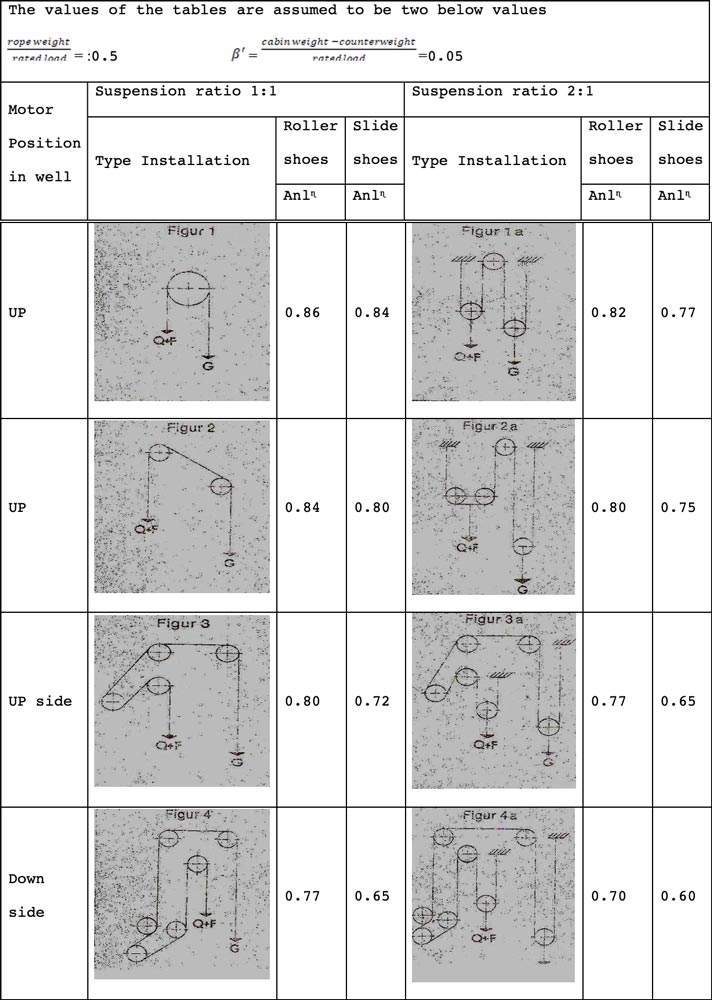

C: Table of Average Elevator Shaft Efficiency:

For normal elevator operation, it is not necessary to calculate any of the situations, so below is the average value of well efficiency for conventional elevators calculated by Formula 1:

D: Efficiency Factor for Special Cases:

The average value of wells presented in Table 2 can be increased or decreased, depending on the type of parts and additional equipment. It should be noted that the information presented in Table 2 is based on system values of 0.5 = percent balanced = ![]() and 0.05 = (rope weight)/(rated load). The following coefficients can be used for different values:

and 0.05 = (rope weight)/(rated load). The following coefficients can be used for different values:

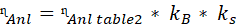

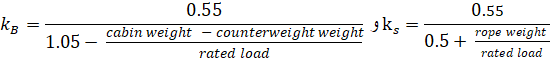

So:

Conclusion

Based on the importance of minimal power required in elevator motors, this article notes that one of the parameters affecting motor power puts the shaft efficiency under investigation.

Parameters affecting the shaft efficiency include friction of rails and shoes (on the cabin and counterweight sides), type and number, and arrangement of pulleys. Also, parameters, such as the cabin weight to the rated load and the rope weight to the rated load, are effective, which is presented in detail in this article.

Also read: Lifts Without Ropes: How Many Shafts and Cars Are Needed?

Get more of Elevator World. Sign up for our free e-newsletter.