The future of elevator maintenance is in IIoT, according to Intellithink CEO

The pandemic and its associated economic crisis has precipitated a contraction of incredible and unanticipated proportions. One need only survey the recent Institute for Supply Management and Federal Reserve reports to see the damage to the real economy. However, there may be something of a silver lining to this crisis: while the lockdowns and decline in consumer demand directly hurt business, they simultaneously offer many on the supply side a pause to engage in much-needed modernization efforts, perhaps especially those in the building-transportation space. Most importantly, these efforts should be led by the integration of Industrial Internet of Things (IIoT) technology with existing and new elevators and escalators.

After working with clients in the vertical-transportation (VT) domain, I have observed firsthand how onerous service costs can be to manufacturers and service providers. Regularly scheduled maintenance checks, which remain the dominant strategy today, are enormously costly and resource-intensive. However, it would be similarly costly to recommend manufacturers avoid engaging in these regular service visits, as any mechanical problems have the potential to manifest in devastating consequences. This is where IIoT comes into play.

Servicers can harness the capabilities of IIoT to employ the most up-to-date and data-driven predictive-maintenance technologies to mitigate otherwise exorbitant upkeep costs. We at Intellithink leverage IIoT to forecast potential equipment failures well ahead of time, thus reducing the need for costly in-person maintenance visits, while retaining a commitment to safety and regulatory compliance. Such analysis occurs constantly with the assistance of real-time data, which regular service visits can never match. This gives maintenance professionals and elevator/escalator owners the power of remote monitoring and instantaneous notifications and diagnostics. Furthermore, IIoT integration has the potential to provide additional data to manufacturers to supplement existing R&D efforts. IIoT technology also allows servicers to forecast their inventory needs more accurately, thus reducing wasteful accumulation of parts in imprecise anticipation of equipment failures.

Dutch elevator consultancy Liftinzicht utilized similar IIoT-based predictive-maintenance services to realize maintenance cost reductions of 30% annually and fewer equipment failures. As the economy still reels from the ongoing effects of COVID-19, savings like these could help companies with predictably thin profit margins stay afloat.

One of the most attractive features of an IIoT-based predictive-maintenance solution is that it need not exclusively apply to new elevators and escalators. My work with clients in this realm has primarily focused on retrofitting legacy elevators with ambient intelligent technology, and we have seen remarkable success. The apparent cessation of much economic activity in India gives building managers and elevator manufacturers the opportunity to upgrade existing equipment to reliably cut service costs without sacrificing safety.

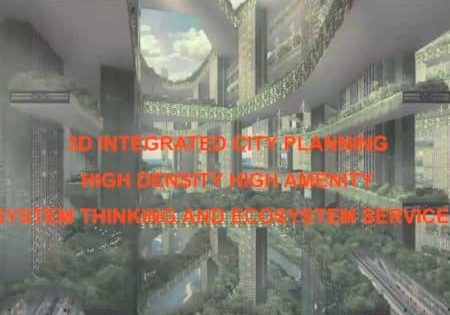

In addition to ours and Liftinzicht’s solutions, the IBM Watson platform and KONE have realized the enormous capacity of IIoT to cut elevator maintenance costs. These solutions have also found value as tools to monitor and meaningfully evaluate usage data. Such statistics can assist building managers and service specialists in analyzing equipment depreciation and energy consumption, which, in turn, creates safer elevators, reduces wasteful downtime and allows buildings to optimize their elevator usage. This essentially means they can use the information to maximize efficiency by more accurately determining peaks and building more productive maintenance schedules. IBM has even gone so far as to suggest that this form of analysis in elevators is part of the broader movement toward artificial intelligence (AI) and smart cities, an initiative in which India hopes to lead.

Developments in cloud computing, sensor technology and machine learning have provided further reason for the VT and adjacent industries to be enthusiastic about the near future of IIoT-based predictive maintenance and monitoring tools. Current-signature analysis, which principally utilizes electrical, rather than mechanical, signals to offer predictive maintenance, has the capacity to revolutionize IIoT-oriented solutions by cutting costs even further and enhancing the “plug-and-play” characteristics of these solutions that render them so enticing to facilities managers and VT service specialists.

In Europe, Semiotic Labs experienced a high degree of success employing current-signature analysis in other industries, and Intellithink has produced patent-pending technology that provides current-signature analysis to the Indian market for the VT and other industries. With the current rate of technological progress and an increasing dependence on AI, now is the best time for those involved with elevators or escalators to renovate their maintenance strategies for the modern economy.

References

[1] instituteforsupplymanagement.org/ISMReport/MfgROB.cfm?SSO=1 [2] richmondfed.org/research/regional_economy/surveys_of_business_conditions [3] mendix.com/blog/liftinzicht-built-iot-enabled-smart-app-helped-cut-elevator-maintenance-costs-30-percen/ [4] ibm.com/watson/stories/kone [5] schindler.com/us/internet/en/service-maintenance/schindler-ahead/benefits.html [6] ibm.com/blogs/watson/2019/01/how-kone-incorporated-ibm-watson-to-make-its-elevators-smarter [7] smartcities.gov.in/content/innerpage/smart-city-features.php [8] semioticlabs.com/resources/motor-current-signature-analysis

Get more of Elevator World. Sign up for our free e-newsletter.