An exploration of one of the biggest problems in today’s U.S. elevator industry and what is being done about it

Problems

As the elevator market has slowly recovered from the 2008 economic downturn, hiring has steadily increased in the industry. In the U.S., such growth has been spurred by the wider construction industry, where spending has increased in excess of 5.5% over the past two years.[1]

However, according to a recent Reuters report by Jason Lange, most CEOs at U.S. corporations have reported “significant problems in finding workers with the skills they need.” A survey released on December 1, 2014, found that among rich countries, the U.S. “is a relative laggard when it comes to educating its youth, especially in skills like math, which is seen as vital in an increasingly high-tech global economy.” The report also noted a slowdown in U.S. college enrollment growth since the 1980s “because the demand for high-skill workers could be outstripping their supply.”[2]

Other studies show an even more critical situation, such as one released in late February by Deloitte and The Manufacturing Institute, which begins:

“The U.S. faces a need for nearly 3.5 million manufacturing jobs over the next decade, and two million of those jobs are likely to go unfilled due to the skills gap. . . . Two parallel studies – ‘The Skills Gap in U.S. Manufacturing: 2015 and Beyond’ and ‘Overwhelming Support: U.S. Public Opinions on the Manufacturing Industry’ – draw together perspectives from U.S. manufacturing executives and the American public that reveal American manufacturing companies face a significant skills gap over the next decade, largely fueled by baby boomer retirement and too few young people who see the industry as a career destination.”[3]

This trend is something nearly all skilled trades have already been experiencing. According to ManpowerGroup, the skills shortage extends to the construction industry, as well, and will become more acute in the next few years. Skilled trades have seen the biggest talent shortages this decade.[4] ELEVATOR WORLD has heard from many company owners and managers at various meetings and conventions over the past year that, particularly, the elevator industry is suffering from a low skilled-worker supply. Other comments from business owners who (understandably) want to remain anonymous include:

- “It is really becoming a pain to try to cover all our work with the available employees that we have.”

- “We find that too many mechanics, in general, don’t have the skills or knowledge base that should be required to hold the ‘elevator mechanic’ title. Although this has always been a concern, it seems to be increasing slightly of late with tech calls where mechanics should have known ‘basic’ information.”

Another source asking not to be named informed your author of a tangential movement in the industry:

“There is a trend by the largest elevator companies to drive supplier costs down to unhealthy levels, while continually increasing the workload (support, customer service, order processing, etc.) on those suppliers by having to deal with inadequately trained personnel on their end. In the past, larger customers provided substantially larger volume orders that made the extra work worth it, but in the last few years, volume has decreased, their increasing bureaucracy stifles business relations, and their countless untrained personnel [who are] brought in to replace the ‘early retired’ workforce has flipped the scales. That being said, the smaller independents out there are starting to eat up market share based on the weaknesses of the larger companies, which is where we see opportunity for continued business improvement and mutually beneficial results.”

Older workers who have not yet retired are in the midst of retiring at a rapid rate, taking their experience with them. Many retired early during and shortly following the 2008 economic crisis, when many companies implemented hiring freezes that did much to “decimate recruiting.”[5] Now that skilled trade industries are seeing sustained growth again, they need to hire replacement technicians. The challenges are the training of new, younger workers and, if possible, the retention/reacquisition of experienced ones. Comments received included “There’s nowhere near the amount of experience there was in the industry 10 years ago,” which is even more of a problem in our industry due to the proliferation of older equipment still in service and the amount of it that requires modernization.

Solutions from Companies

Matt Watkins, executive vice president, Marketing, ThyssenKrupp Elevator Americas, spoke for most OEMs when he said:

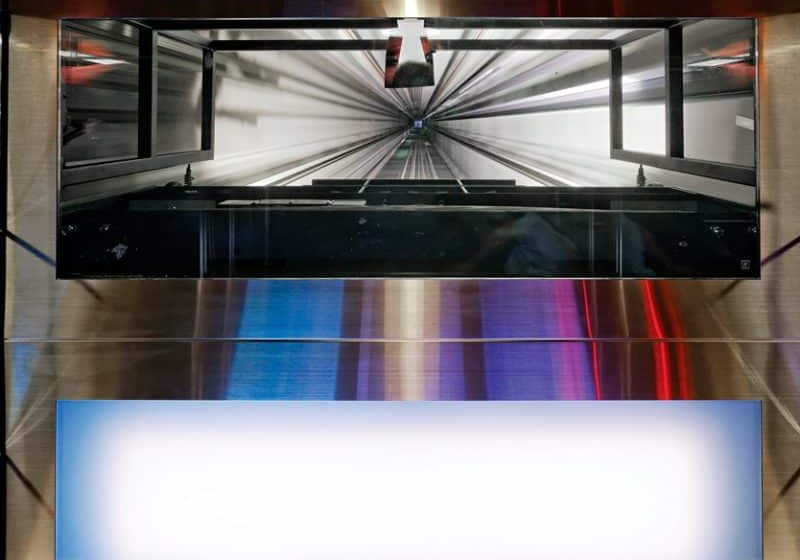

“Order intake and sales were up this year. We are seeing the machine-room-less products continue to grow and have successfully launched the endura MRL. . . that has been well received by the market. Modernization is a key area for the industry and will continue to be a large growth sector, based on the need for tenant retention for existing buildings to compete with the new technologies offered and energy reductions.”

As companies hire more and land bigger and bigger jobs across the U.S. (and particularly in New York City [“Business Booming in Big Apple,” EW, March 2015]), elevator firms such as SmartRise Engineering, Inc. and TEI Group have developed their own in-house training and safety programs (EW, January 2015). Bobby Schaeffer, president/owner of D & D Elevator in Elmsford, New York, explained that his company is working on creating simulation software that will allow its technicians to practice working on their sequence-of-operations skills. It is also breaking up each section of a generic control system that would allow them to learn a step-by-step process of troubleshooting a standard elevator control system.

D & D also has greater goals of educational offerings and hiring-practice modifications to improve the skills of both its own and others’ workforce, as Schaeffer outlined:

“We have experienced a labor shortage, and I think that without a group effort, it will get worse. The way we have chosen to deal with this problem is to focus our efforts on getting new candidates who have the educational background of at least a degree in Electrical or Electromechanical Engineering. These are candidates who already know how to study, and, as a result, have a faster learning curve. We have scheduled a trip to visit a technical training facility outside the U.S. where we have had good success in recruiting candidates. Their ability to learn is above average, and their work ethics are second to none. As we finalize our efforts for recruitment, we will ask other companies if they would be interested in hiring some of these quality candidates.

“In our latest five-year business plan, we have created a project to streamline our educational process. I think there has been more of an industrywide emphasis on training in recent years, and I would like to think that is a result of better training opportunities. We have seen the need to modify our hiring practices but not in the way most would think. During a shortage, people tend to want to cut corners and accept a lesser candidate for a position, but our company and several others have chosen to make the investment to streamline the education and make up the difference in workload through productivity.

“We are considering implementing a boot-camp version of the Certified Elevator Technician (CET®) program in which we can work with potential candidates to increase the pace of learning by funding an educational facility where our apprentices and technicians can get hands-on education through lab training offering 24/7 access; this way, if a candidate or technician wants to learn at a faster pace, we can schedule training during off hours. We will be creating a pilot program, and if this is successful, we would want to open it for all who wish to participate.

“We have also hired a full-time safety and training manager to visit each employee while working in the field to ensure they are working safely and helping them with our hands-on education requirements. The manager has already put a series of short, one- or two-week training units in place using the Elevator World, Inc. Educational Focus book that has been well received by our employees.”

When asked if he had any ideas on what the rest of the industry should do to counter its skilled labor challenges, Schaeffer responded:

“Any company that has not made the decision to make a bigger investment in its employees’ training and safety will be a dinosaur within the next three to five years. Companies that do not have an affiliation or offer training opportunities should consider getting involved in the educational process. Ultimately, I see a worldwide shortage that will further complicate things here in the U.S. The amount of elevator installations in other parts of the world is as much as 10 times that of the U.S. If we don’t start working together, then our perceived level of competition over well-trained workers will be the least of our problems.”

When asked if the National Elevator Industry Educational Program (NEIEP) has noticed a shortage in industry skills, National Director John O’Donnell replied:

“In fact, there are a number of skills that need enhancement in our industry. Our industry is moving faster than ever before. The demands of having less time and more equipment to be responsible for, on the service end of the business, and quicker installation times on the construction side, require a much more efficient game plan. On the service end of the business, the service tech needs the skills to recognize, troubleshoot and repair a problem almost intuitively. The same approach with a different goal is expected of the construction mechanic. But, we all know such knowledge and skill is not mere intuition; it must be taught. “

O’Donnell also addressed whether NEIEP has recorded any job shortages of skilled elevator workers:

“Not as yet. Hiring across the country is on the rise, which is not a bad thing. But, there is an issue that is sneaking up on the industry, and that is retirement. Our industry has many dedicated individuals currently working who are quickly approaching retirement age. Who will fill this void? These are the people who are currently being relied on for the majority of the work and who possess the most skill due to their experience. Has the rapid pace of our industry — with the reliance on these ‘go-to people’ in the field — left a void?”

To counter these challenges, O’Donnell said:

“NEIEP has made a concerted effort since 2008 to move to a more efficient ‘hands-on approach’ to learning the craft. In order to meet the potential void, we have increased our offerings all across the program. We have new hands-on labs for mechanics who wish to enroll in continuing education. We have responded to the National Elevator Industry, Inc.’s request and are in the process of rolling out a national safety certificate program.

“There are pressures with changes in state code and legislation that have obligated the program to address or, in some cases, readdress topics within the curriculum. [These include] scaffold certification, licensing, signaling and rigging, cardiopulmonary resuscitation, OSHA and high rescue, just to name a few. Some demands are regional, but with the industry’s mobile workforce, we modify the national program to meet the requirements of the job.”

Karl Keller of elevator control valve manufacturer Maxton Manufacturing Co. (p. 82) explains some of what his company is doing to educate industry workers:

“We are imparting all the knowledge we have about valves and hydraulic elevators that we can. Based on quotes and feedback, our efforts seem to have a positive impact on those that desire the information and apply it within their profession. As with anything, some get more out of training than others. I know the reach and impact must be bigger to meet the obvious need; therefore, Maxton will continue to look for additional opportunities and angles to spread the word with new product additions, like the electronic valve, as well as tried-and-true general hydraulic elevator principles. Also, we implemented our 4.0-credit valve-training class for CET in 2011 and provided additional support to NEIEP and the Canadian Elevator Industry Educational Program in 2012-2014 with tools and technical input for the organization’s implementation and curriculum.”

Solutions from Associations and Services

Elevator World has also noticed an increase in educational material demand during this tangible rebound in the industry one source called “more stable than we have seen during the last few years.” The CET and Certified Accessibility and Private-Residence Lift Technician (CAT®) programs with which it promotes in partnering with the National Association of Elevator Contractors (NAEC) have seen steady growth throughout the last two years. A minimum of six Continuing Education articles are printed in EW each year, though the last two years have seen more than that due to increased demand. Elevator World has also released several new educational products to the industry over the last year that appeal to a broad audience, such as “A Manager’s Safety Notebook,” Installation Manual (2014 Edition), “User Reference Guide for Elevator Ropes” by Brugg Lifting and Elevator Engineering.

Since many of Elevator World’s products can now be purchased digitally, immediate access to a wide range of educational material is available. This also contributes to the company having had one of its strongest Educational Department years since 2009. It is to release additional educational resources this month, such as the 2015 Field Employees’ Safety Handbook, Safety Training for Elevator Service DVD, a second volume of the aforementioned Educational Focus and the Vertical Transportation Industry Profile (2014 Edition). Continuing education alone realized a 51% increase in the number of students enrolled and tests taken over the last year. The states’ moves toward licensing, certification and required education have driven this. Several states (Mississippi, Oklahoma, Indiana, Arkansas, Montana and Wisconsin) recently joining the existing list of those that have previously approved Elevator World as a continuing-education provider (Georgia, Alabama, Virginia, Washington, Florida, Kentucky, Pennsylvania and West Virginia) contributed greatly to this figure.

NAEC Executive Director Teresa Witham explained similar good news from her organization:

“Education has moved to the forefront as a requirement for today’s elevator companies. During the past year, NAEC has seen the CET Educational Program numbers grow by more than 25%. NAEC is excited to advise of the newest educational program – the Vertical Transportation Management Program (VTMP). This unique, personnel development program was created by industry professionals specifically for the vertical-transportation industry. The VTMP is geared towards field personnel aspiring to management roles, existing general managers requiring an appreciation of field operational issues and non-industry recruits seeking a fast-track working knowledge of the industry.”

Schaeffer also offered remarks on the CET program:

“This program has been very helpful to my company, as well as many other companies across the country. Several states have now adopted licensing and continuing education, and that has helped to push all educational entities to provide a better level of apprenticeship and continuing education. All the educational programs in the industry are very good; I just wish all organizations would include additional safety courses, like OSHA 10 or 30 – similar to what is required in the CET program.”

As NAESA International Education Director Jim Runyan writes in “The Complexity of Codes” (p. 80), “State and local jurisdictions, ASME, and manufacturers (to name a few) often provide training for interested parties to better clarify the standards that govern elevator and escalator installations.” The strong support of training and education by so many industry associations and companies doubtlessly means the future of this expanding industry is in good hands.

Get more of Elevator World. Sign up for our free e-newsletter.