Straight to the Top: Innovation in the Future World’s Tallest Tower

Jul 1, 2015

UltraRope is a big reason why KONE won Kingdom Tower contract.

The past few decades have brought dozens of historic innovations in architecture and buildings. For example, the tube structure created by Fazlur Khan paved the way for Chicago’s Willis Tower and heavily influenced today’s tallest standing tower, Burj Khalifa in Dubai. Game-changing advances like this have led to skyscraper-filled cities in which billions of people live around the world. Yet, by 2030, the modern city will be vastly different from what it is today. With the number of people living in cities rising 30% to 5 billion, paired with other drivers of urbanization, cities must continue to grow up rather than out.

For years, it seemed the growing height of buildings outpaced elevators’ ability to transport tenants without switching elevators, not to mention the lucrative space multiple elevator shafts cost buildings.

Demand for taller towers is rising as quickly as the towers themselves. For years, it seemed the growing height of buildings outpaced elevators’ ability to transport tenants without switching elevators, not to mention the lucrative space multiple elevator shafts cost buildings. With today’s proposed and in-development supertall skyscrapers reaching one km (approximately 3,280 ft.), existing hoisting materials are too heavy to reach these great heights. Steel ropes can weigh up to 60,000 lbs., consuming tons of energy over the course of a year. Additionally, tall buildings are subject to building sway, forcing elevators to be out of service on particularly windy days. This is a major inconvenience for the hundreds of residents and employees that live and work in these buildings.

Enter UltraRopeTM

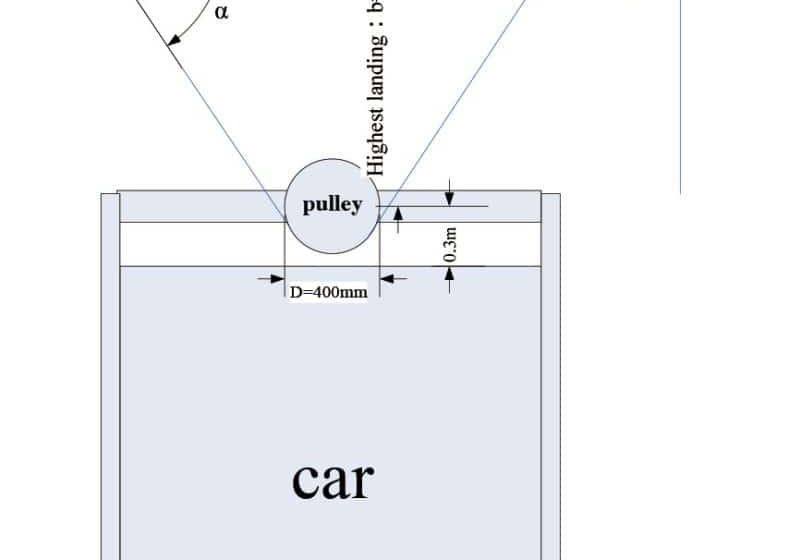

KONE set out to solve the problem of elevators’ inability to reach great heights several years ago. The goal: Develop a lightweight, durable material that would enable elevators to reach higher than ever before. The alternative to traditional heavy steel cables would reach up to 1 km.

In researching and developing alternative materials, KONE identified carbon fiber as a contender, given the substance had already been used to reduce weight in the aviation and automotive industries. The carbon fiber material serves as the hoist’s core, which is covered with a polyurethane high-friction coating that is highly resistant to wear and abrasion. This means reduced rope stretch, extending the rope’s life. Today’s steel cables are typically changed every 7-10 years. KONE’s UltraRope lasts twice as long.

Energy savings will also be a factor, as the groundbreaking technology will support the design of more sustainable, higher-performance buildings better equipped to meet the demands of the urban environments of tomorrow. For a 500-m-tall building (approximately 100 stories), the annual cost savings could reach 15%. However, as building heights increase, the projected annual energy savings of an 800-m-tall building could be as much as 45%.

Servicing the World’s Tallest Tower

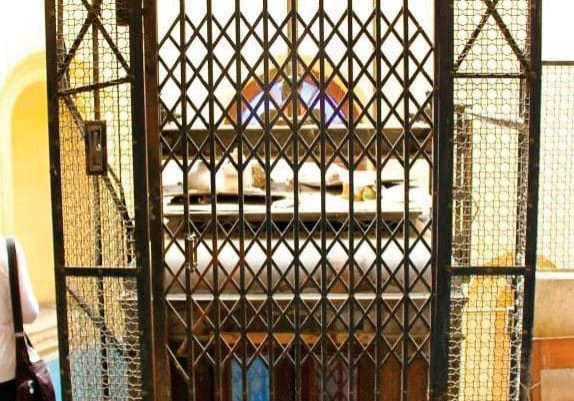

In 2015, KONE won the order to implement all the vertical transportation in what will become the world’s tallest tower once completed, Kingdom Tower in Jeddah, Saudi Arabia. Upon its completion in 2018, the building will have the world’s highest elevator rise at 660 m, spanning 252 floors.

In total, KONE will install eight escalators and 57 elevators, two of which will leverage the revolutionary UltraRope.

Kingdom Tower is and will be a feat in design, architecture, engineering and construction, as it sets a new precedent for what humans can create.

KONE won the order based on its innovative and high-quality products, specifically UltraRope, and the company’s signature People Flow Intelligence solutions. KONE’s local expertise also played a role in the decision, as the company has a team based in Areeco, Saudi Arabia, with a strong track record of success in the Europe, Middle East and Africa region.

The Construction Journey at Kingdom Tower

After two years of meticulous planning and design, KONE kicked off the first phase of vertical-transportation installations in the tower in May 2015. Last January, the project team arrived onsite in Jeddah, preparing the building for the transportation methods. Pre-installation activities include fitting the elevator system’s guiderails, which will begin later this year.

The next phases of the project include installing the elevator cars in the buildings central tower, in addition to manufacturing and delivering the solutions.

Kingdom Tower is and will be a feat in design, architecture, engineering and construction, as it sets a new precedent for what humans can create. The tower represents a continued movement up, instead of out, for urban areas. This movement fueled the innovation and creation of UltraRope, which will only become more important as the need for upward transportation to greater heights continues.

Get more of Elevator World. Sign up for our free e-newsletter.