Supporting Schindler’s Success

Sep 1, 2022

Engineer Wah Leung takes problem-solving to the next level.

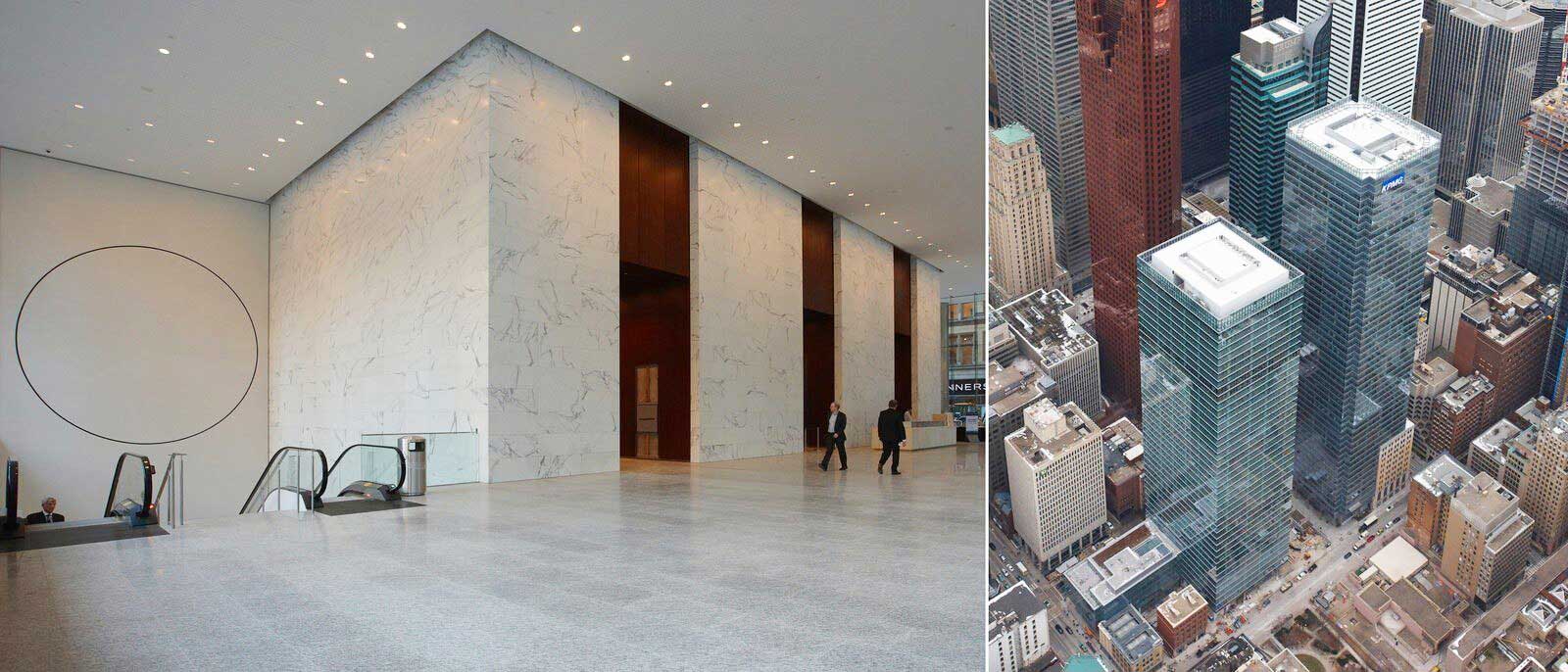

If Schindler performed a major vertical-transportation (VT) system modernization or new installation in the Toronto area, chances are field engineer Wah Leung was involved. Joining Schindler Canada in 1993 after working for Schindler in his native Hong Kong since 1980, Leung — an electronics expert — “moves seamlessly and most effectively between high-current applications such as elevator drive components and any type of control circuits,” says colleague John Egan, vice president of Field Quality & Excellence at Schindler Canada. Among major VT projects for which Leung contributed are, in Toronto, Scotia Plaza, a major modernization that was an ELEVATOR WORLD Project of the Year in the Elevators, Modernization category (EW, January 2022); 390 Bay Street, a multicar modernization completed in 2000; Metro Toronto Convention Centre; The Well, a multitower, mixed-use development, on which construction is ongoing; 480-488 University, a combined modernization and new-installation project where a new tower was constructed atop an existing and open office building, completed in 2021; Toronto Hilton, a five high-rise elevator modernization completed in 2003; 36 Toronto Street, including the first PORT installation by Schindler Canada in the city; and Bay Adelaide East, a multiphase office development completed in 2016.

Despite having more than 40 years’ experience in the industry, Leung continues to dedicate himself to learning, Egan said, observing:

“He is held in the highest esteem across our company and our industry. He has held positions including project manager, field supervisor and field engineer, with success on all fronts. Leung has demonstrated himself to be one of our industry’s great problem-solvers. Whether a problem — however intermittent — is mechanical, electrical, electronic, hardware or firmware or other software-related, Leung will find it and Leung will fix it. He is boundlessly resourceful in getting the information he needs to correct a design, assembly, installation or operational matter. He does this with an unmatched commitment, stamina and calm. In the most challenging of issues and circumstances, Leung keeps himself and his teams focused and winning.”

Leung grew up in a large family in Hong Kong, with 20 people living under one roof. He graduated with a degree in electrical engineering from Hong Kong Polytechnic University in 1980 and joined Schindler Hong Kong shortly thereafter. He worked there for more than 13 years before taking an engineering job with Schindler Canada in 1993. By that time, he had a wife and two young children — a boy and a girl — and they all moved to the Toronto metropolitan area. His son, Chun Wai Leung, has also joined Schindler Canada’s Field Engineering division.

Technology has come a long way since the 1980s, when Leung worked almost exclusively on relay logic elevator control equipment. Relay logic controllers gave way to transistor logic systems, which in turn gave way to programmable logic controls and to our current microprocessors, but relay systems remain Leung’s favorite. Regardless, he says he enjoys learning how elevators and computers work together. “For me, I can understand how computers work — what they are doing and why they are doing it,” Leung says. “There’s always something interesting and deeper to learn, and the evolving technology is why I am still learning.”

Leung has worked as a field engineer in Toronto, Ottawa, Montreal and across Canada, and has earned a strong reputation for his troubleshooting skills. One instance, approximately 10 years ago at a historic office building in downtown Toronto, involved a customer that eventually awarded Schindler Canada the Scotia Plaza modernization job. For the historic office tower, Schindler took over the maintenance of elevators that were being maintained by a competitor. Prior to Schindler’s involvement, several of these units would be reported to be shut down for months. Enter Schindler Canada and Leung, “who went through his troubleshooting and problem-solving procedure,” ultimately resulting in the customer getting the units back online before the modernization started. Egan is convinced that the success of that project very much contributed to Schindler being awarded the Scotia Plaza modernization contract.

There’s always something interesting and deeper to learn, and the evolving technology is why I am still learning.

— Schindler Field Engineer Wah Leung

Leung is skilled at ferreting out even unexpected problems, Egan says:

“He understands the whole system. He will go into a microprocessor-based system where someone before him thought the problem was a board or software, and [Leung] will discover it was a little mechanical switch that was at the bottom of the problem. He says, ‘No, it wasn’t that; it was this.’ He sees the whole picture and gets to the root of a problem without spending too much time or money on the wrong components. He finds out what the issue is, however mechanical or nonmechanical it might be.”

Changes in elevator technology have continued to evolve, Egan points out — from relay logic, transistor logic, programmable logic controls through to our current microprocessor controls. Learning the ropes with relay logic, Leung still takes a “basic, stepwise approach” to problem-solving, in terms of “what’s supposed to be happening, why something is happening and what is not happening,” Egan says, continuing:

“[Leung] is able to apply that problem-solving approach to almost any kind of technology, which makes him so valuable. He can fix anything. It’s not just muscle memory; it’s not something that he kind of remembers but doesn’t understand: it’s something he knows from the bottom up. He’s stayed current with industry changes and kept up with them in terms of what’s supposed to happen. He understands why an output needs to be high or low. He understood relay controllers from first principles and the basics, and applies that clear approach to any and all technologies he’s confronted with now.”

Egan hopes Leung stays on with Schindler for another few years, but understands that retirement is approaching. In his spare time, Leung enjoys golfing and playing with his grandchildren. Before he retires, Leung intends to “continue to train and pass [his] knowledge on to younger mechanics and engineers.”

Get more of Elevator World. Sign up for our free e-newsletter.