Sustainable Building: In-house LEED Specialists Provide Expertise

Apr 1, 2013

by Jens Holtgrefe and Silke Richter

Buildings account for roughly 40% of global energy consumption. Lighting, heating, elevators and other building services use a lot of power. Rising energy costs, scarce resources and growing environmental awareness have led to a change in the way buildings are designed, built and modernized around the world. The advantages of sustainable building are obvious: conservation of natural resources, lower running costs and improved occupant well-being. Ultimately, everyone benefits – building owners, architects, general contractors and planners, residents and tenants, as well as manufacturers of energy-efficient and green products. But, meeting the requirements of international certification standards for buildings and products such as the U.S. Green Building Council’s Leadership in Energy and Environmental Design (LEED®) certification process calls for integrated planning and expert customer support. In an effort to meet these challenges, more than 100 ThyssenKrupp Elevator employees around the world – most of them in the U.S. – have been trained in the LEED rating system over the past few months, and further training programs will follow shortly in all regions.

Whether in the Americas, Europe or Asia – roughly 50,000 LEED projects have already been registered worldwide, and the figure continues to rise. There are four levels of certification – “platinum,” “gold,” “silver” and “certified,” which depend on factors such as use of sustainable building materials, lower building operating costs and various occupant health aspects. Choice of site, energy efficiency, materials and resources, and indoor environmental quality are just a few of the key criteria.

As resources become scarcer and more expensive, certification is having an increasing influence on demand and on the value of a property for sale or lease. In many cases, it is also simply a question of prestige or of ecological cost assurance.

International corporations in particular ask for certification when leasing buildings. It ensures certain building standards are met and generally keeps utility costs for heating, energy and water at acceptable levels. But, even buildings that are not certified to standards such as LEED, Building Research Establishment Environmental Assessment Method (BREEAM) or DGNB (German Sustainable Building Council) face growing demands for lower operating costs. Using intelligent automation technologies to control temperature, lighting and passenger transportation systems can be of great assistance in this respect.

Customer Requirements

With or without certification, meeting the requirements for sustainable building calls for early collaboration between specialists from various disciplines, an intelligent overall strategy, and constant optimization during the design phase. The competency of the various specialists is of elementary importance, allowing companies like ThyssenKrupp Elevator to address customer requirements quickly and competently from an early stage. The current initiative to train LEED professionals also strengthens the awareness of employees for today’s demands and the need for sustainable infrastructure.

“We see ourselves as a competent partner,” says Patrick Tenter, product manager for sales of volume products at ThyssenKrupp Elevator in Düsseldorf, Germany, and one of the graduates of the LEED program.

Tenter adds:

“LEED is still in its infancy in Germany: Many customers are obtaining certification for the first time. There is still a great deal of uncertainty. And, that is exactly why it is so important that we ourselves know what requirements have to be met and how the certification process works. Our support saves customers a great deal of time and creates additional value. I was skeptical to start with, but after completing the program I have to say that I’ve learnt a great deal about sustainable building, and I now know how our solutions can make a valuable contribution – at no additional cost to our customers.”

Forward-Looking Innovations

Throughout the ThyssenKrupp Group, sustainability is a major driver of innovation and a continuous process to improve economic, ecological and social performance. The company translates this idea into efficient, safe, customer-oriented mobility solutions. ThyssenKrupp Elevator offers a portfolio of energy-efficient, ecologically friendly innovations that reduce the energy requirements of its elevators and the building without compromising performance, design, safety or comfort, meeting the requirements of LEED in a wide variety of categories.

Efficiency Classes for Standard and High-Rise Elevators

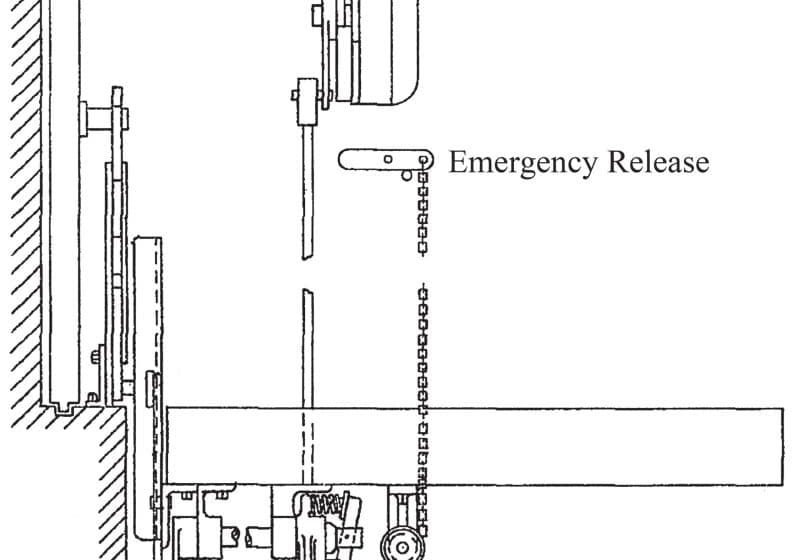

Efficient components such as gearless synchronous drives, frequency control and energy recovery systems turn installations into energy savers. Many countries have already awarded numerous elevator models an energy efficiency class “A” rating, the highest rating under VDI Guideline 4707. Innovative control systems deliver further savings potential. For example, the E.COR controller, developed at the Neuhausen, Germany, plant, has a sleep mode function – when the elevator is not in use for a lengthy period, the controller switches off all unneeded components step by step until only the external call button is still activated. That makes high energy savings possible even in standby operation.

The same applies to escalators. ThyssenKrupp Elevator offers a variety of standby functions such as variable speed and stop and go. The company’s engineers have also developed the Energy Efficient Controller (EEC), a device that measures the load on the escalator and controls energy input accordingly. The plug-and-play control system is suitable both for new installations and as a retrofit kit.

For high-rise buildings, ThyssenKrupp Elevator has also developed mobility solutions that meet the highest standards of ecology, efficiency and profitability. Foremost among them is the TWIN system, which consists of two cabs run independently one above the other in the same shaft. The operation saves both space and material, because TWIN reduces shaft requirements by one-third compared to conventional installations. The intelligent destination-selection control system minimizes empty journeys and waiting times, enabling passengers to reach their destination faster. To provide customers with reliable and transparent data, ThyssenKrupp Elevator carries out its own extensive analyses, from pilot installations, complete life cycle analyses (LCAs) and measurements during test operation to comprehensive energy calculations for new systems. In addition, ThyssenKrupp Elevator carries out comparative measurements of energy use before and after modernization. On various projects in the U.S. and Germany, energy savings of up to 70% were achieved.

New Approaches for Lighting and Indoor Environmental Quality

LEED points and building certification are not just influenced by complete systems; individual components also play an important role for sustainability. For example, the use of modern LED lighting technology can achieve energy savings of up to 90% and significantly longer lifetimes than conventional fluorescent lighting. LED lamps also deliver better light yield, are far more robust and provide higher output. Alongside energy savings, aspects such as air and indoor environmental quality are also relevant for LEED certification. Elevators from ThyssenKrupp Elevator can implement various indoor air quality management plans drawn up for LEED certification. In the U.S. ThyssenKrupp Elevator has had its cabs certified by the independent safety testing organization Underwriters Laboratories as compliant with California’s Section 01350 standard for low emissions.

LEED Projects around the Globe

More than 350 buildings worldwide with passenger transportation systems from ThyssenKrupp Elevator have been LEED certified and include office towers, hotels and airports. More are to follow soon, such as the new headquarters building of the major Spanish bank BBVA in Las Tablas, Madrid. For this project ThyssenKrupp Elevator is manufacturing and installing 96 elevators including 61 “synergy” and nine high-performance elevators for speeds of up to 4 mps. All the elevators in this complex are equipped with regenerative drives. Energy created when the cabs are slowed is converted into electricity and fed back into the building’s power grid. This approach reduces energy requirements for the drives by around 30% compared to conventional designs. The elevators are remotely monitored by a central system. The permanent analysis of operating data permits targeted diagnostics, optimizes service call-outs and ensures a high degree of availability for passengers. In its plans for the new BBVA headquarters, ThyssenKrupp Elevator has combined environmental protection with comfort, meeting the criteria for LEED Gold certification.

Alberto Tappe, Product Strategy and Sustainability manager at ThyssenKrupp Elevator in Spain and another graduate of the LEED training program, is also convinced of the benefits for customers:

“We put our professional expertise at our customers’ disposal from the earliest planning phase. Our freshly acquired knowhow enables us to harmonize specific customer wishes and needs with the strict requirements of a possible LEED certification process at an early stage and match them up perfectly. Quite apart from specific LEED-related issues, I can put my knowledge of green buildings and the various facets of sustainability to use in other projects, too. The program content is tailored exactly to our requirements – that is important for our global expertise and our growth in all regions.”

Jeremy Robinson, Modernization manager and program graduate from the U.S., had the same experience:

“I had worked on a few certification projects in Utah before I attended the training program. With the knowledge I have now, planning would not only have been easier, it would probably also have been possible to complete the projects more quickly. From my experience, I have learned that when it comes to sustainable building and LEED certification, it is all about the details. Without training, it will become increasingly difficult to reconcile individual customer wishes with requirements for certification.”

Design visions and environmental compatibility can quickly start to diverge. This can even start with the understanding of glues and coatings used on the job site, something Robinson has found from past experiences. “Our expertise enables us to identify where points might be deducted at an early stage and work with the building owner and architect to find remedies. That avoids mistakes and ultimately saves money,” Robinson said.

LEED Program’s Passing Grade – 85%

The special LEED training program, which is intended for employees in sales, production, sustainability and environment departments, comprises an eight-part series of online seminars. Participants must also supplement their knowledge using a study manual with numerous practical tests. The subject matter is complex. In addition to the aforementioned criteria such as energy and atmosphere, water efficiency, materials and resources, and indoor environmental quality, participants must also know all about the ecological performance of their own parts and products – in particular environmental advantages and the effect they have on successful certification. At the end of the training program, the aspiring LEED professionals from ThyssenKrupp Elevator must pass an external exam developed and administered by the Green Building Certification Institute (GBCI), which also carries out the LEED certification process. The institute was established in 2008 by the U.S. Green Building Council, which developed the LEED rating system and is one of the most important associations of leading representatives from all sectors of the building industry. The multiple choice test for LEED Green Associates comprises 100 questions worth a total of 200 points. To pass the test, candidates must achieve 85% (i.e., 170 points).

Dr. Claudia Schmidt-Milkau Discusses ThyssenKrupp’s LEED Training

With its training initiative for LEED professionals, ThyssenKrupp Elevator has taken a role in sharing knowledge for sustainable building. Expertise and ongoing training are essential when it comes to providing comprehensive and targeted advice to customers, explains Dr. Claudia Schmidt-Milkau, senior vice president for sustainability at ThyssenKrupp Elevator.

The 100th employee has just successfully qualified as a LEED Green Associate and thus a certified LEED expert. How important is sustainable building for ThyssenKrupp Elevator?

For us, it is a really important future market. There are currently more than 50,000 LEED projects around the world, most of them in the U.S., where there is a clear trend toward LEED certification. But, there are also other international certifications such as BREEAM, DGNB, HQE and Building and Construction Authority Green Mark, and a growing number of buildings built to these standards. Experts agree that in many countries almost all new public buildings will have to meet these standards in the foreseeable future. Demographic change, urbanization and globalization are among the global trends. But, the need for “more” is set against the finite nature of natural resources, which are becoming scarcer and more expensive. With our engineering skills, energy-efficient products and concentrated expertise, we enable our customers to meet the rising demand for “more” in better ways and gain competitive edge. As a global enterprise, we are also called upon to explore new paths and develop innovative products and services for sustainable infrastructure and resource efficiency. Our commitment to that has been implemented in the mission statement of ThyssenKrupp.

Why is it so important for the company to train its own employees in this area?

Sustainable building is an integrated approach that takes in all parts of a building and all stages of its lifecycle. The knowledge of everyone involved in the project is key to the success of the building – and our business is no exception. We also see ourselves as an irreplaceable partner to our customers. In the LEED training program, our employees don’t just learn to pass an abstract exam, they also gain an insight into how sustainable building works – with or without certification. Participants also gather extensive knowledge on energy and water efficiency, selecting suitable materials, protecting undeveloped land, and providing a healthy indoor environment; all of which give them a good overall grounding in sustainable building. Coupled with our knowledge of energy-efficient passenger transportation systems, this puts us in a position to address the needs of a project from an early stage and provide quick and competent support from the start of the project through to final certification.

What has been the reaction of your employees?

Before the training starts, it ranges from enthusiasm to skepticism. After all, the employees have a lot of learning to do for the exam, as you have to answer 85% of the questions correctly to pass. But, afterward, our employees notice they have profited from the program and have learned a lot that will help them in their work. Our sales staff in particular gain a new channel to customers as advisors. At ThyssenKrupp Elevator and throughout the ThyssenKrupp Group, we attach great importance to employees who want to help us shape the present and the future. For this we all have to keep learning and adapting to changing markets.

Get more of Elevator World. Sign up for our free e-newsletter.