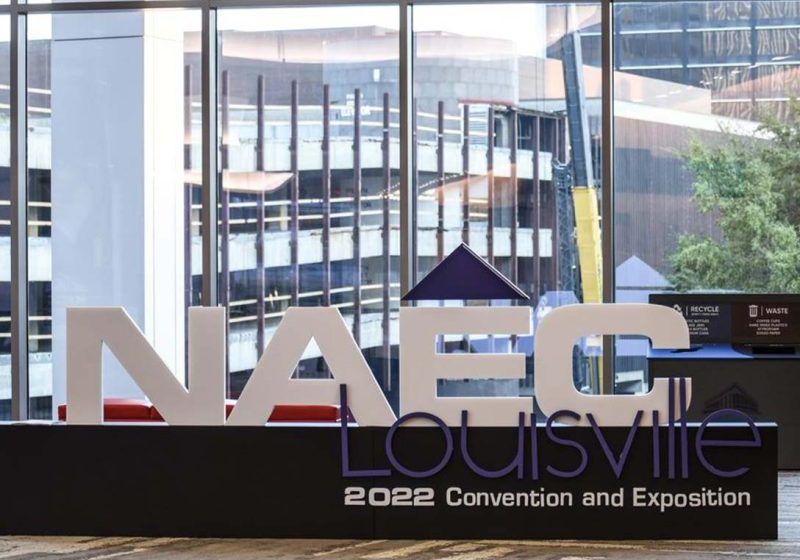

Systems and Tools for Public and Field Safety

Dec 5, 2022

Solutions from North American manufacturers

MRL Package

Delco Elevator Products has introduced the D-MRL Package, a nonproprietary machine-room-less (MRL) elevator system compatible with the controller and fixtures of a customer’s choice. With a maximum rise of 260 ft and cab height of up to 10 ft, the package comes in a rail- or beam-mounted layout with a pancake- or sausage-style machine and is available in high or low voltage. It is also available for seismic zones. Included items for the subsystems are:

Guiderail and machines

- Rail bracket — car/counterweight (CWT)

- Guiderail with fishplate and hardware — car/CWT

- Traction machine

- Traction support and hitch

Structure and suspension means

- Sling, platform, isolation and rail lock

- Frame — car/CWT

- Sheave — car/CWT

- Wire rope — hoist

- Wedge sockets

- Compensation rope

- Compensation anti-swing device

Door and entrance

- Door operator

- Landing header assembly

- Entrance, including car and landing sill

Hoistway components

- Governor

- Governor tension sheave

- Governor rope

- Safety gear with retainer

- Oil buffer — car/CWT

- Pit ladder

Cab

- Top rail

- Car door

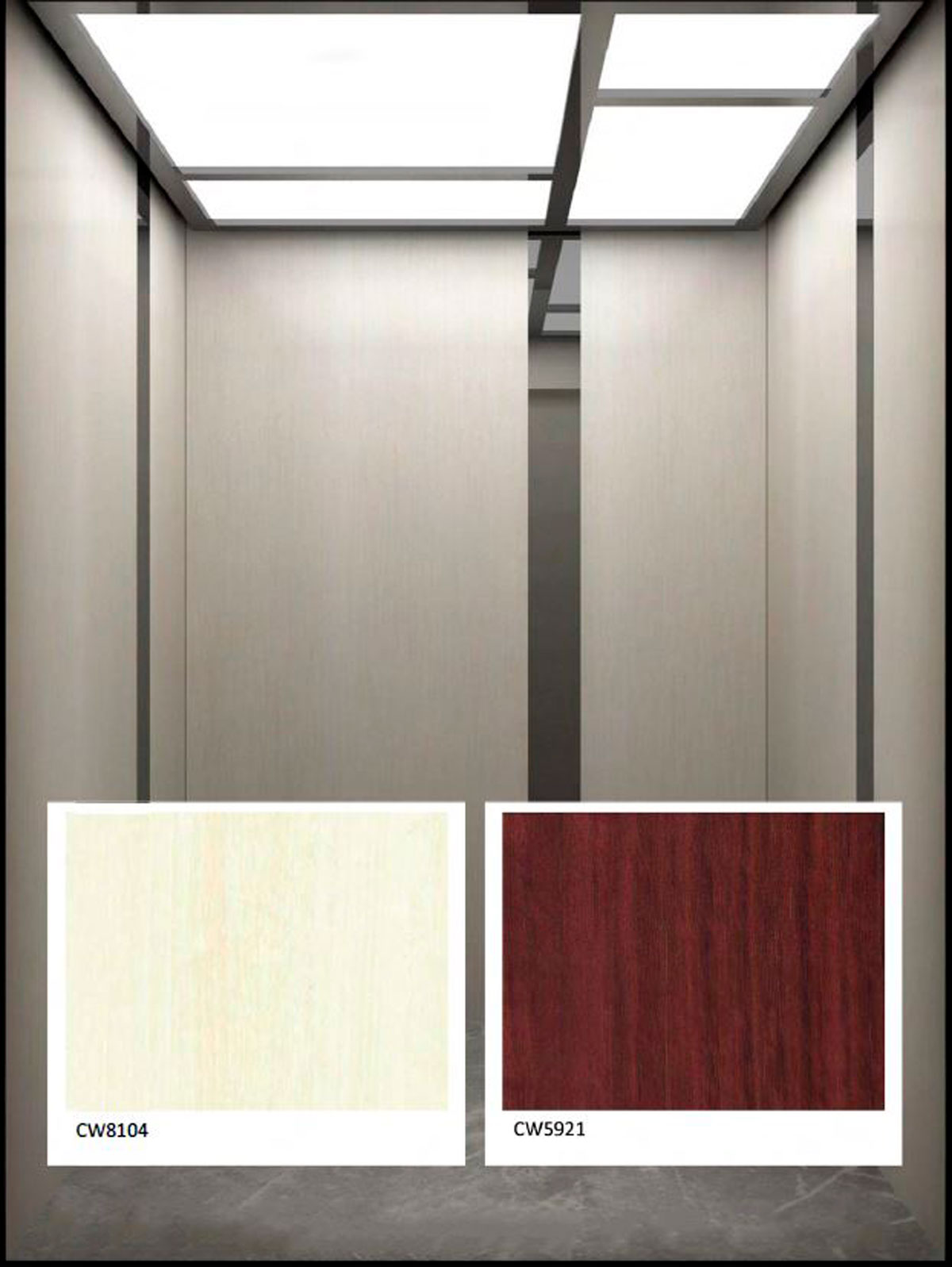

- Interior (laminates, floor, ceiling)

Compact Home Elevator

Cambridge Elevating Inc. of Cambridge, Canada, offers the E50 compact, electric, machine-room-less (MRL) elevator, touted as “the most affordable and easily incorporated home elevator in North America.” The compact MRL design means no machine space is required, and the unit fits into a 50-in-X-50-in hoistway. E50 comes with powered, automatic, soft-opening bifold cab doors, interiors in an array of move-in ready melamine finishes and reduced hoistway cost since no continuous rail support wall is required. It meets all ASME A17.1/CSA B44 national elevator safety codes. Ideal for larger residential developments, the lift solution includes:

- Touch-and-go operation

- Car operating panel with position indicator and built-in telephone

- Dual-illuminated pushbuttons in the car and at each call station

- Cushioned roller wheels for a soft, comfortable ride

- Automatic elevator homing/parking

- A 24-month limited warranty

- Faster installation

- Reduced shipping costs

Sanitation Device for Escalators and Moving Walks

Adams Elevator Equipment Co. introduces the Ultra UV and Ultra UV PRO, devices designed to fight viruses and bacteria on escalator and moving walk handrails without the use of harsh chemicals. Ultra UV uses germicidal ultraviolet (UV)-C light to treat the handrails at a short distance. This directly damages DNA and RNA — the genetic materials of bacteria and viruses — to prevent their rapid spread. The device is easily installed inside the escalator or moving walk to help ensure passenger safety and disinfect handrails in an efficient and environmentally friendly manager. Ultra UV PRO works similarly to Ultra UV, but operates at a higher efficacy, providing an enhanced level of protection.

Range of New Aluminum Products

Wurtec recently rolled out a range of aluminum products: Aluminum Rope Clamps, the Roebling Clamp Lift Bar, the Ratchet Beam Clamp and the Aluminum Rope Shortening Clamp. Designed to hold two ropes together or create a lift point on a rope, Aluminum Rope Clamps feature grip-enhancing internal grooves to increase capacity. Bolts are torqued to 96 ft-lbs. In certain applications, reaching the required torque can be difficult. The use of Wurtec’s spanner wrench (#60-10040479) is recommended to help achieve leverage.

The Roebling Clamp Lift Bar creates a secure hitching point for shortening wire ropes. Once the clamps are in place, the lifting bar is attached just above them. Technicians can attach hoists to the oblong links on the lifting bar. The lift bar’s simple installation allows for easy shortening of wire ropes. Key features include:

- Weight capacity of 30,000 lb

- Easy installation

- Durable design

The Rachet Beam Clamp is a safe, portable tool that provides a secure anchor point in hard-to-reach places. It conforms to OSHA 1926.502 and is an approved anchor point for fall protection for up to two people. The clamp can also be used for hoisting and can support up to 3 T (6,600 lb). To use, attach a lifeline or safety line to the safety bolt at the bottom of the clamp, then open the jaws of the clamp. Position the clamp on the end of the 11-115 telescopic attaching rod and lift toward the desired location. Weighing 8 lb, the attaching rod extends up to 10 ft. When the clamp trigger comes into contact with the beam, it snaps closed and into a locked position. The clamp works on any beam with 4- to 8-in.-wide flange.

The Aluminum Rope Shortening Clamp allows the user to lift the elevator car by clamping onto the hoist ropes directly above the hitch plate. Once the shortening clamp is in place, a hoist can be attached between it and the crosshead. Slack can then be created in the hoist ropes, allowing for easy shortening of the rope at the hitch plate. To prevent the cable from slipping, be sure the shortening clamp is positioned with grooves on each rope and torqued to the proper specification.

Get more of Elevator World. Sign up for our free e-newsletter.