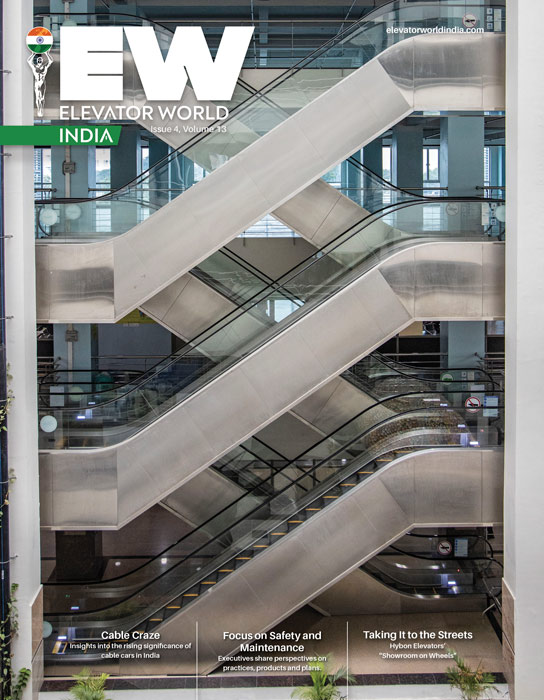

Ratan Sehgal (RS), managing director, Hybon Elevators & Escalators Pvt. Ltd., shares insights with your author (YP) about its “Showroom on Wheels.”

YP: When and how was Hybon Elevators’ Showroom on Wheels envisaged? What is the unique selling proposition, and how does it benefit the consumer and vertical-transportation (VT) industry?

RS: Hybon was the first elevator company in India to have an elevator showroom. Since customers could physically see, touch and feel the elevator, response was overwhelming. Our second showroom came up at our factory in Noida. However, it was not practical for every customer to visit our showrooms, particularly due to apprehensions related to COVID-19. So, we decided to make a showroom that can go to the customer: the Showroom on Wheels.

About Hybon

Established in 2010, Hybon Elevators & Escalators Pvt. Ltd. provides an array of VT equipment, from home passenger and luxury commercial elevators to heavy-duty auto elevators, escalators and moving walks. Components such as car and landing operating panels, along with intercom systems, are also available. The company has a factory that produces car cabins and frames along with a showroom in Noida and a showroom in Delhi, in addition to the showroom on Wheels. Hybon products are IS 14665-approved per the Bureau of Indian Standards and compliant with EN 115 and 81 standards.

YP: Describe the processes of creating the Showroom on Wheels.

RS: There were essentially four key components:

- Creating the concept: This involved customer input and input from our internal departments.

- Reliability: It was challenging for our design team to ensure the cars could withstand jerks and vibrations while in transit.

- Detailed designing: This was done through a professional interior designer.

- Execution: Construction was entrusted to a professional bus-body-building company.

YP: What are your long-term plans for the Showroom on Wheels? What other roles can it play?

RS: Depending on the acceptability of this concept, we may add to the fleet to cover a larger geography. We believe that, through the Showroom on Wheels, awareness about the usefulness and safety of an elevator can be taken to a much larger audience. We plan to conduct short awareness campaigns for safety, and training for handling emergency situations and evacuations.

YP: Several fatal accidents have recently made headlines. In your opinion, what are the possible causes of such incidents, and how can they be avoided?

RS: The most common causes of accidents are inferior quality of materials and poor maintenance. Accidents can be avoided by using materials per specifications and performing periodic elevator maintenance. Special emphasis should be placed on safety-critical components like ropes, door safeties and limit switches.

YP: What are your views on the need for strictly enforcing safety and maintenance in VT, along with the existing norms stipulated for compliance and procedures?

RS: Proper safety and maintenance hinges on periodic maintenance/service; timely replacement of safety-critical parts, like ropes; refusal to take safety shortcuts; and ensuring work is performed by technically qualified and experienced technicians.

Get more of Elevator World. Sign up for our free e-newsletter.