Technological Development of the Ultra-High-Speed Elevator with a Speed of 1,200 mpm

Jan 1, 2017

How the world’s fastest elevator was developed

by Tetsuya Nakayama, Hideka Matsuoka, Yoshiki Higashida, Jun Ohtsuki, Keizo Nakamura and Kazuhisa Mori

This paper was presented at  Madrid 2016, the International Congress on Vertical Transportation Technologies, and first published in IAEE book Elevator Technology 21, edited by A. Lustig. It is a reprint with permission from the International Association of Elevator Engineers

Madrid 2016, the International Congress on Vertical Transportation Technologies, and first published in IAEE book Elevator Technology 21, edited by A. Lustig. It is a reprint with permission from the International Association of Elevator Engineers  (website: www.elevcon.com).

(website: www.elevcon.com).

In recent years, an increasing number of skyscrapers and large-scale buildings have emerged worldwide, including in Asia and the Middle East. This has created the necessity of ultra-high-speed and high-capacity elevators. Hitachi, Ltd. has developed an ultra-high-speed elevator with a speed of 1,200 mpm to meet the growing demands of the world. This article describes the technologies behind the driving and control system, safety and riding comfort of the world’s fastest elevator.

Introduction

The global increase in construction plans for high-rise buildings of heights 500-600 m has called for a higher demand for elevators with higher speed and transportation efficiency.[1] In response to this, Hitachi developed the world’s fastest (per Hitachi internal data as of September 14, 2015) ultra-high-speed elevator with a rated speed of 1,200 mpm.

We have integrated the following technologies in this ultra-high-speed elevator:

- A driving and control system to achieve the world’s fastest speed

- A governor and braking device that ensures a safe emergency stop

- Car guide equipment that prevents lateral vibration to reduce the blocked-ear sensation.

In addition, this elevator will be in operation at the ultra-tall Building Complex in China in 2016.

Background of Development

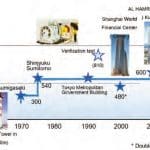

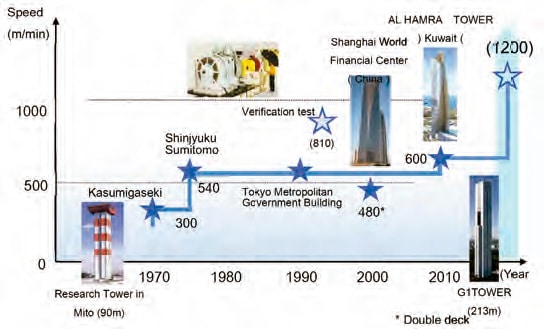

The development history of ultra-high-speed and large-capacity elevators began in the late 1960s for domestic high-rise construction — the “Kasumigaseki building” in particular. At that time, the highest rated speed for passenger-use elevators in the domestic market was 150 mpm, whereas the rated speed required for the Kasumigaseki building was double that at 300 mpm. Therefore, we constructed an elevator research tower with a height of 90 m in Mito Works (Ibaraki prefecture, Japan), which was the tallest of its kind in the world at that time.

Accurate speed-control technology, and vibration- and noise-suppression devices, as well as high-speed safety devices, were developed and tested in that tower. This facilitated the completion of the high-speed elevator capable of traveling at a speed of 300 mpm, as required by the Kasumigaseki building.[2]

Following this success, elevators with higher speeds were developed one after another, until the time in 1993, when the world’s fastest elevator with a rated speed of 810 mpm was developed.[3]

However, the Asian market (the Chinese market, in particular) has grown rapidly since the beginning of the 2000s. At the same time, elevator companies around the world entered the market, causing us to face tough competition.

In addition, especially in the Middle East, new buildings tend to be ultra tall and on a large scale. This brought forth the requirement for ultra-high-speed and large-capacity elevators for those buildings.[4] Because of that, we continued to develop technologies to further improve safety, efficiency and comfort based on the knowledge of super-high-speed elevators that had been attained so far. To strengthen its product-development capabilities in the global market, we started the use of the 213-m-tall research tower “G1TOWER” that was the world’s tallest (per Hitachi internal data as of September 14, 2015) research facility for elevators in 2010.[5] As a response to the demands for high-speed and large-capacity elevators, we performed numerous experiments to enhance its products in consideration of safety, comfort and the environment.

Development Details and Features

Driving and Control System Technology

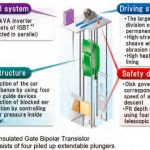

A 330-kW permanent-magnet synchronous motor that adopts a thin profile yet achieves the high output required to operate the elevator at a speed of 1,200 mpm was developed (Figure 3).[6-10]

The electrical power loss during the lift’s acceleration was reduced by applying laminated steel-plate rotors to the motor. This resulted in the reduction of the traction machine’s width by 13%, while increasing the rated output of the motor by approximately 1.3 times (as compared with the maximum-output traction machine used in conventional Hitachi products via internal Hitachi data as of September 2015).[11]

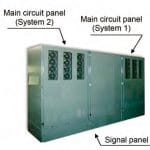

Furthermore, the output capacitance of the inverter that operates the motor is 2,200 kVA, which is one of the world’s largest for elevator use. The capacity and space saving of the control panel (Figure 4) was increased by placing two inverters consisting of four insulated-gate bipolar transistors connected in parallel. The wires forming the main rope of the car were reinforced to improve the specific strength, thereby reducing the weight to 30% less than that of the conventional rope.

Safety-Device Technology

A braking device that utilizes high-heat-resistant linings has been developed. In the unlikely event where an abnormality is detected by the elevator system, this device is able to withstand the heat generated by the braking action required to safely stop a car from a rated speed of 1,200 mpm. In addition, for elevators in ultra-tall buildings with long travels, the limit of the descending speed is set at 600 mpm, whereas the ascending speed is set at 1,200 mpm.[12] This is because the blocked-ear sensation caused by air-pressure differences is prominent in passengers during the elevator’s descent.

The governor, having a compact design, is able to measure the elevator’s speed during its ascent and descent through the usage of independent functions, thereby ensuring the safety of passengers. Furthermore, the depth of the pit in the hoistway is decreased significantly through the application of the four-step extendable telescopic buffer (Figure 6), instead of enlarged buffers.

Car Structural Technology

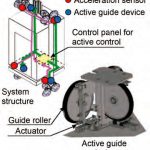

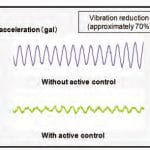

For the comfort of passengers, active roller guides were installed (Figure 7) at the four corners of the car (top, bottom, left and right) to reduce vibration caused by the car’s plurality of vibration modes. Moreover, the disturbance to the car caused by the slight warping of guide rails and the wind pressure is being restrained, thus reducing approximately 70% of the vibration. This provides passengers with comfortable rides during high-speed operation (Figure 8).[13-16]

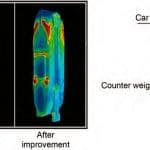

In addition, an air-straightening capsule structure was developed by conducting fluid analysis (Figure 9) and wind-tunnel tests to reduce aerodynamic noise and fluid forces induced when the car and its counterweight pass by each other. Furthermore, riding comfort is produced by installing atmospheric-pressure-control equipment, which adjusts the air pressure to reduce passengers’ blocked ear sensation due to the changes in atmospheric pressure during the lift’s travel.

Evaluation Testing Equipment

The combined evaluation of the large traction machine and its high-capacity driving-control apparatus was carried out at the G1TOWER (Figure 10). Safety devices, such as safety gear, governor and buffer, were also tested and verified there. In addition, evaluations of the car’s vibration and noise were carried out during super-high-speed operation while applying active guides, which significantly reduced the car vibration caused by rail curvature, and an air-straightening cover, which reduced wind noise.

A ground equivalence testing device (Figure 11) was used to replicate the inertial forces of the actual conditions during the elevator’s travel. This device simulated the conditions of a 1,200-mpm operation, which allowed the testing of the elevator that would otherwise have been impossible due to the shortage of travel at the G1TOWER. The performance of the traction machine, brake and control panel were also inspected during the test.

In the car noise test (Figure 12), the wind tunnel simulated the conditions of elevator operation at 1,200 mpm so the effect of the air-straightening capsule could be inspected. The results of the noise evaluation at G1TOWER and the fluid analysis were then compared, and the simulated conditions were refined until the evaluation techniques had high precision.

An atmospheric-pressure-simulation apparatus (Figure 13) was used to detect the atmospheric pressure-change patterns during the elevator’s ascent and descent. Through this process, the appropriate atmospheric-pressure pattern was determined for each elevator specification (rated speed and travel), and its effectiveness was confirmed.

Conclusion

The 1,200-mpm elevator for the Guangzhou CTF Finance Centre (Figure 14) is scheduled to start operation in 2016. We aim to complete the elevator by pursuing high-quality performance and high-precision construction techniques, while making full use of simulation analysis and realistic elevator performance evaluation in the G1TOWER.

Looking ahead, we will continue working toward the development of elevators that offer added value to support the ever-increasing construction of taller and larger buildings in overseas markets. Moreover, we will continue to utilize the new technologies and insights that have been obtained through these developmental activities for ultra-high-speed and high-speed elevators and other products to provide safe, comfortable and convenient building environments at a global scale.

- Figure 1: A timeline of Hitachi’s super-high-speed elevator

- Figure 2: The main technological development of the 1,200-mpm elevator.

- Figure 3: A 330-kW permanent-magnet motor

- Figure 4: A 2,200-kVA control panel

- Figure 5: Governor corresponding to each speed of ascent and descent

- Figure 6: Four-step expandable telescopic buffer

- Figure 7: Installed active guide rollers at the top, bottom, left and right

- Figure 8: Ground test results of the car disturbance

- Figure 9: Fluid analysis: (l-r) the effects of an air-straightening capsule; a car and a counterweight pass each other.

- Figure 10: G1TOWER

- Figure 11: Ground equivalence testing device

- Figure 12: Condition of operation test

- Figure 13: Atmospheric-pressure-simulator apparatus

- Figure 14: Conceptual drawing of Guangzhou CTF Finance Centre

References

[1] Nathaniel Hollister and Dr. Antony Wood, “The Tallest 20 in 2020: Entering the Era of the Megatall,” ELEVATOR WORLD (2013).

[2] Hideo Miyao, “The Control of Gear Less Traction Machine with a Speed 300 m/min,” Hitachi Review, (1968).

[3] Masayuki Shigeta, “Technology Development of the Ultra-High-Speed Elevator with a Speed of 810 m/min,” Hitachi Review, (1993).

[4] Toshiaki Nakagawa, Hideya Kohara, Youichi Sekimoto and Shigeo Nakagaki, “World Fastest Elevator,” Toshiba Review, Vol. 57 No. 6 (2002).

[5] Akihiro Omiya, ”World’s Highest Test Tower (G1TOWER) Changes the Next Generation Vertical Movement of City,” Hitachi Review, (2010).

[6] Toshiaki Nakagawa, “New Technology of Elevator,” Shindenki 2012.10, p. 6-19, (2012).

[7] Kazuhiro Tanaka, Yasuaki Takeda and Shinichi Noda, “Advanced Technologies of Elevators for TOKYO SKYTREE,” Toshiba Review, Vol. 67 No. 11 (2012).

[8] Satoru Kato, Takanori Kamatsu, Kosei Miyamoto and Kazufumi Hirabayashi, “Driving Control System of Super High-Speed Elevators,” Mitsubishi Denki Giho, Vol. 86 No. 8 (2012).

[9] Zbigniew Jerry Piech, “Super High Rise Propulsion Technology,” Elevator Technology 20: Proceedings of Elevcon 2014, p. 283-289 (2014).

[10] Zbigniew Jerry Piech, “Permanent Magnet Machines for Elevator in Super High-Rise Buildings,” CTBUH 2014 Shanghai Conference, p. 824-829 (2014).

[11] K.Mori, N.Ohnuma, T.Sakoda, Y.Matsumoto and T.Yabuuchi, “Power Converter with Parallel Connected IGBTs for Ultra-high Speed Elevators,” IEE Jpn. Proc. of Ind. Applicat. Soc. (JIASC2015), p. 295-300, (2015).

[12] Mitsuyoshi Imura, Takeshi Niikawa, Naohiro Shiraishi, Takuo Kugiya and Takashi Kobayashi, “Safety Device for Super High-Speed Elevator,” Mitsubishi Denki Giho, Vol. 86 No. 8 (2012).

[13] Masaji Iida and Yoichi Sakuma, “Passengers’ Comfort in Super High-Speed Elevator,” Mitsubishi Denki Giho, Vol. 86 No. 8 (2012).

[14] Shigenori Matsuo, Masaaki Hirai and Sueyoshi Mizuno, “World’s Fastest Elevator (1010 m/min),” Toshiba Review, Vol. 60 No. 4 (2005).

[15] Kenichi Kikuyama, “About the Fastest Elevator of Taipei 101,” Kenchikusetsubi & Shoukouki, No. 55 (2005.5).

[16] Hiroaki Mizuguchi, Toshiaki Nakagawa and Yoshiaki Fujita, “High-Speed Elevator in Taipei 101,” EW (2005.9).

Get more of Elevator World. Sign up for our free e-newsletter.