The 1876 Centennial Exhibition, Conclusion

Jan 1, 2014

Part one of this series examined Otis Brothers’ steam-powered elevators, and part two examined American hydraulic elevators, both as seen through the eyes of engineer Alois Riedler (1850-1936), author of the Austrian delegation’s report on elevators displayed at the 1876 Centennial Exhibition in Philadelphia. Riedler’s report, titled Personen- und Lastenaufzüge und Fördermaschinen (Passenger Elevators, Freight Elevators and Mine Hoists), offered readers a concise summary of 19th-century American elevator technology. It also included an illustrated discussion of an elevator designed by Mégy, de Echeverria and Bazan of Paris, which was the only European system exhibited.

Although Riedler referred to the “firm of Mégy, Echeverria & Bazan” in his text, the trio’s precise business and partnership structure is unclear. Léandre Mégy (1835-1910) graduated from the École des Arts et Métiers (Aix) in 1851, and he began his pursuit of an improved hoist design in 1864, working in partnership with Pétrus Dubar. The result of their efforts was a hand-powered winch or hoist that featured a hand-operated brake that permitted the user to control the speed of descending loads. Mégy and Dubar appear to have jointly filed a patent application in November 1864; however, when the patent was finally awarded in 1867, Mégy was the sole patentee: French Patent No. 78,476, Perfectionnements Dans les Appareils de Levage (Improvements in Hoisting Apparatus). At the same time, he also appears to have begun his association with José de Echeverria and Felix Bazan. Unfortunately, very little is known about Mégy’s new partners. De Echeverria was a Spanish engineer who had participated in the 1867 Paris International Exposition; thus far, nothing is known about Felix Bazan.

The team, identified in the French press as civil engineers, continued the development of Mégy’s original invention, with the goal of making the braking action an automatic function of the hoisting mechanism. Their efforts resulted in an improved device patented in France, the U.K., the U.S. and Germany: French Patent No. 90,391, Embrayage-Frein à Ressort Intérieur (June, 16 1870); Great Britain Patent No. 1,777, An Internal Spring Coupling and Brake for Transmitting, Stopping, or Regulating Motion (June 22, 1870); and U.S. Patent No. 143,293, Improvement in Internal Spring Couplings and Brakes (September 30, 1873). Evidence supporting the presence of a German patent derives from engineering periodicals that, beginning in the mid 1870s, refer to the Stauffer-Mégy patent elevator (Stauffer was a German engineer who partnered with Mégy to patent the invention and facilitate the system’s manufacture in Germany by Dreyer, Rosenkranz & Droop in Hanover and Briegleb, Hansen & Co. in Gotha).

The team’s multinational patent strategy was paralleled by an exhibition and publicity campaign that also crossed national boundaries. Illustrated articles about the Mégy, de Echeverria and Bazan elevator included: “Treuil Sans Retour de Manivelle Avec Frein Automoteur,” Le Génie Industriel (May 1866); “Über den Aufzug mit Regulirtrommel (System Mégy),” Polytechnisches Journal (1874); “Stauffer-Mégy’s Aufzug mit Regulirtrommel,” Polytechnisches Journal (1876); and “Remplacement des Escaliers par des Ascenseurs Avec Moteur Hydraulique (Système Mégy, Echeverria et Bazan),” Nouvelles Annales de la Construction (February 1876). While this steady press coverage very likely ensured Riedler was familiar with this elevator prior to attending the Centennial Exhibition, it is also possible he had a firsthand opportunity to examine this design. Mégy, de Echeverria and Bazan had exhibited their elevator at the 1873 Vienna Universal Exhibition. Their participation in this exhibition was also thoroughly illustrated and discussed by French engineer Hippolyte Fontaine (1833-1910) in his book Description des Machines les Plus Remarquables et les Plus Nouvelles a L’exposition de Vienna en 1873.

The innovation at the heart of Mégy, de Echeverria and Bazan’s design was described as an improved spring coupling or clutch mechanism, which was initially proposed for use in hand-powered freight hoists. The spring coupling was housed inside a hollow hoisting sheave and connected to the drive shaft such that, when the shaft rotated in the direction that raised the load, a series of flat leaf springs pressed against the interior of the hoisting sheave and thus rotated it, winding the hoisting chain. When the hoist was stationary, the springs remained pressed against the sheave and held the load in place. To lower the hoist, the operator simply pressed down on the crank or hoisting lever in the opposite direction, which released the pressure on the interior springs and allowed the hoisting sheave to rotate in reverse. The speed of the descent was controlled by the amount of pressure applied to the hoisting lever. It is important to note that this invention was originally designed for use on simple winches that carried goods on a hook or similar device. The basic nature of this system was revealed in patent drawings (Figure 1).

Mégy, de Echeverria and Bazan’s display at the 1873 Vienna Universal Exhibition reinforced the utilitarian nature of their invention, which was illustrated by a full set of drawings: an elevation, plan and three sections (Figure 2). However, their display also revealed that the team had continued exploring its invention’s potential. These efforts were represented by a design for a belt-driven freight elevator. The series of drawings depicting this application of their invention included two sections showing the installation of the engine, belt drive, counterweight and shaft access gates; a detailed drawing of the engine, belt drive shifter and controller (which included a control lever in the car and control ropes adjacent to the engine); and detail drawings of a “regulating” (safety) sheave located at the top of the shaft (Figure 3). The latter was a new feature attached to the counterweight sheave that utilized a variation of the internal spring system. If the elevator’s speed exceeded a preset limit, the springs inside the regulating sheave expanded and reduced its speed, stopping the car if needed.

This safety device was later referred to as a “poulie régulatrice ou poulie parachute” (regulating or parachute pulley). The latter designation was, perhaps, intended to capture the gradual nature of its action, which allegedly resulted in a smooth and safe stop if the hoisting cables broke. This characterization of their safety is found in Charles Oppermann’s 1876 article “Remplacement des Escaliers par des Ascenseurs Avec Moteur Hydraulique (Système Mégy, Echeverria et Bazan).” The article described Mégy, de Echeverria and Bazan’s exhibit at the 1875 Paris Exposition (where their design earned a gold medal) and included a detailed set of drawings (provided by the inventors) and an engraving of the full-scale, working elevator that was the highlight of their display. Although Oppermann reported the lift height was, in fact, too short to effectively test the safety device, he also noted that, during the exhibition, the hoisting rope broke three times. While the safety had apparently worked each time, during one of these episodes, the passengers who experienced the unexpected ride were described as “shaking” when they exited the car.

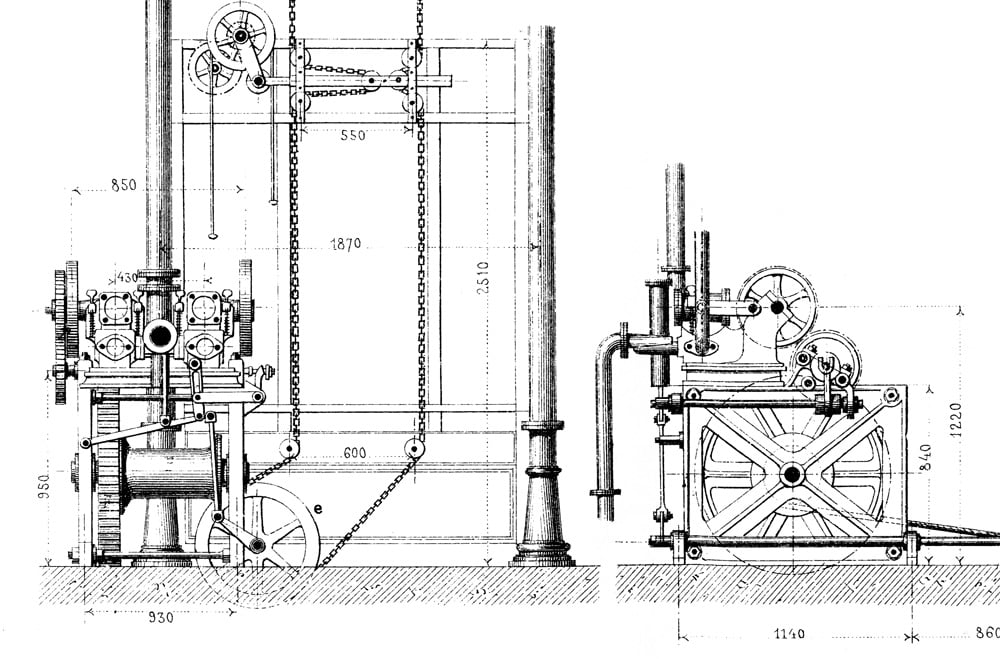

The elevator displayed in 1875 clearly reveals that Mégy, de Echeverria and Bazan had expanded their system’s use beyond factories and freight hoists to include passenger elevators. This effort included utilizing a freestanding engine in place of the typical industrial power system of belts and pulleys. As noted in Oppermann’s title, this elevator employed a “hydraulic motor.” In his account of his group’s 1876 Philadelphia exhibit, Riedler described the engine’s design as following the “System Schmid.” This was a piston-driven, oscillating engine powered by water pressure, which had been designed in the early 1870s by Swiss engineer Albert Schmid (1857-1920). According to an account published in Engineering in 1872, the engine was capable of producing 5 hp per 100 ft. of head (approximately 43 psi). The engraving clearly shows the hydraulic engine, hoisting drum and elevator car (Figure 4). In addition to the working elevator, Mégy, de Echeverria and Bazan also displayed a full set of drawings. However, in a departure from their earlier exhibition strategy, in 1875, they only presented their passenger elevator.

In Philadelphia Mégy, de Echeverria and Bazan’s exhibit included material from both of their prior exhibitions. The drawings prepared for the 1876 exhibition included a series that depicted the original invention applied to a hand-powered hoist, as well as drawings that depicted its use in a passenger elevator system. The hand-powered hoist was illustrated by a new set of drawings similar to those prepared for Vienna (Figure 5). The drawings depicting the passenger elevator were identical to those displayed in Paris. These included two elevations of the hydraulic motor installation and a section through the elevator shaft. The former depicted the use of hoisting chains in place of cables or ropes and the mechanism associated with a control lever in the car, which included control ropes adjacent to the engine (similar to the system found on their 1873 freight elevator) (Figures 6 and 7).

As he had done with Otis Brothers and Lane & Bodley, Riedler provided specifications and cost information for typical installations of Mégy, de Echeverria and Bazan passenger elevators. The specifications assumed a car capacity of 10 passengers (seven seated) and the use of a Schmid engine operating at a water pressure of 3 atmospheres (approximately 44 psi). The operating speeds were given in millimeters per second (mmps), with different speed ranges provided for up and down travel: up speeds were 200–300 mmps (12–18 mpm), while typical down speeds were listed as 500–600 mmps (30–36 mpm). The greater down speeds were possible because the car’s speed of descent was not controlled by the motor; it depended solely on the pressure applied by the operator on the controller, which released the interior springs and allowed the hoisting sheave to rotate. The cost depended on whether the elevator was located inside a masonry shaft or in an open metal framework, such as the one depicted in the exhibition drawings. Guide rails in masonry shafts averaged 60-100 francs per meter (assuming a normative height of 20 m), while their cost in an open-framework shaft was 300 francs per meter. The total costs of installed systems ranged from 8,000–9,000 francs (in an enclosed masonry shaft) to 12,000–13,000 francs (in an open metal framework).

Interestingly, because it employed a “hydraulic motor,” Mégy, de Echeverria and Bazan’s design was characterized by Riedler as a “hydraulic elevator,” and he claimed its advantages included simplicity of construction, comparatively low cost and ease of installation. He also reported that Mégy, de Echeverria and Bazan’s elevators were “built in the German Empire by the Maschinenfabrik Briegleb, Hansen & Co. in Gotha and in Austria by Val. Thumb in Vienna (Mariahilf).” Although these references were doubtless helpful to his German readers, it is interesting that Riedler omitted the name of the French firm that manufactured these elevators. In 1876, Mégy was made a partner in the Paris firm of Sautter-Lemonnier & Co., which specialized in designing and building lighthouse lamps and related equipment. He was charged with overseeing the manufacture of Mégy, de Echeverria and Bazan elevator systems and other inventions designed by the three engineers. Unfortunately, other than the 1876 judges’ citation commending their elevator for its “ingenuity, compactness, and great utility,” there are no detailed records of what American engineers or elevator manufacturers thought about their French colleagues. Nonetheless, this elevator – when compared to contemporary American designs – clearly reveals that engineers on both sides of the Atlantic were faced with similar challenges and that their respective solutions, while parallel in many ways, also had significant differences.

Figure 1: Mégy, de Echeverria and Bazan Hoist, U.S. Patent No. 143,293, Improvement in Internal Spring Couplings and Brakes (September 30, 1873)

Figure 3: Mégy, de Echeverria and Bazan Belt Powered Freight Elevator, 1873, Hippolyte Fontaine, Description des Machines les Plus Remarquables et les Plus Nouvelles a L’exposition de Vienna en 1873 (1874)

Figure 4: Mégy, de Echeverria and Bazan Passenger Elevator, 1875, Charles Oppermann, “Remplacement des Escaliers par des Ascenseurs Avec Moteur Hydraulique (Système Mégy, Echeverria et Bazan),” Nouvelles Annales de la Construction (February 1876)

Figure 5: Mégy, de Echeverria and Bazan Hoist Mechanism, 1876, Alois Riedler, Personen- und Lastenaufzüge und Fördermaschinen (1877)

Figure 6: Mégy, de Echeverria and Bazan “Schmid” Passenger Elevator Engine, 1876, Alois Riedler, Personen- und Lastenaufzüge und Fördermaschinen (1877)

Figure 7: Mégy, de Echeverria and Bazan Passenger Elevator, 1876, Alois Riedler, Personen- und Lastenaufzüge und Fördermaschinen (1877)

Get more of Elevator World. Sign up for our free e-newsletter.