The 1958 Atomium Escalators and Elevator

Nov 1, 2012

The vertical transportation of this famous, unique Brussels structure is given a thorough examination.

The Atomium, a unique building designed for the 1958 Brussels Universal and International Exhibition, has appeared on the cover of ELEVATOR WORLD three times. The most recent appearance was in the June 2007 issue when the cover article was a detailed account of Schindler’s replacement of the building’s original escalators and elevator. The building’s first appearance was on the August 1958 EW cover – that issue included a feature article that described the building’s design, opening and unique elevator system. The August 1961 EW cover included an image of one of the building’s escalators accompanied by a drawing of the building, and the associated article described the building’s escalators. This article will reexamine the Atomium’s original elevator and escalator systems, designed for a mid-20th-century exhibition building that is now a 21st-century tourist attraction.

The 1958 Brussels Universal and International Exhibition was the first world’s fair held after the end of World War II. This fact, of course, also meant it was the first such event during the Cold War. The exhibition’s theme, “A World View, A New Humanism,” was intended to promote the peaceful coming together of all nations in the postwar era. While this lofty goal may have been pursued by the event’s planners and the host nation, the actual exhibition highlighted the growing competition between the U.S. and Soviet Union. Their competing pavilions faced each other and offered visitors differing world views: the Soviets emphasized science and technology (a model of Sputnik I was on display), and the Americans emphasized the virtues of capitalism and democracy (displays included mock voting booths and home furnishings and appliances). However, literally towering over the fairgrounds and overshadowing the political and cultural Cold War feud was the exhibition’s main pavilion – the Atomium.

The building’s principle designer was Belgian engineer André Waterkeyn (1917-2005), who was assisted by Belgian architects André Polak (1914-1988) and Jean Polak (1920-2012). Although the building’s design has been described as symbolizing the peaceful use of atomic power (a topic of great interest in the late 1950s), its form derived, perhaps, more directly from Waterkeyn’s engineering background and interests. According to its designer, the building represented the atomic structure of a “crystal of metal” that had been enlarged 165 billion times. (The Atomium’s total height is 334.6 ft.) The building is composed of nine spheres (each 59 ft. in diameter), which represent the crystal’s individual atoms; these are linked together by vertical, horizontal and diagonal “tubes.” The vertical and diagonal tubes are 10.8 ft. in diameter, and the horizontal tubes are 9.8 ft. in diameter. In addition to the vertical tube or central column, the building is supported by three “bipods” that also contain stairways.

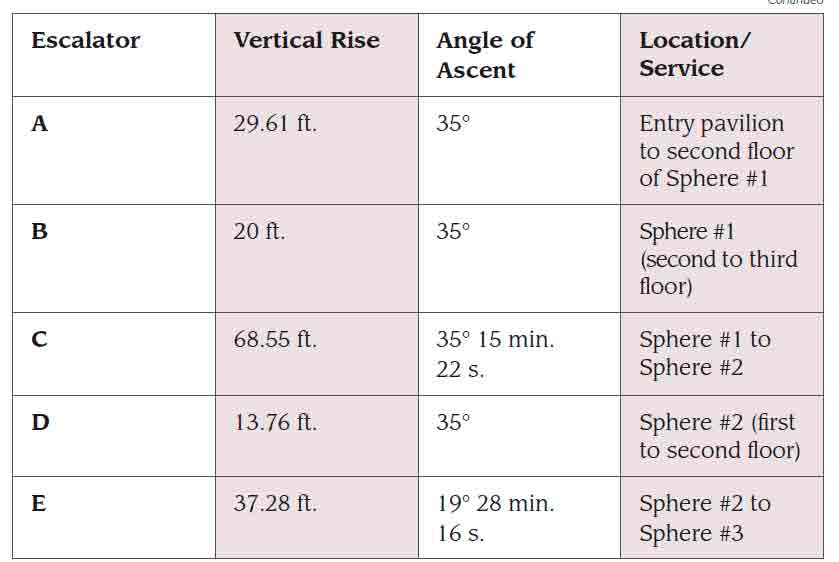

Each of the nine spheres was assigned a number. The lowest sphere (#1) rested atop a one-story entry pavilion. This and seven other spheres contained exhibition spaces, while the highest sphere (#9) housed a restaurant and observation area. The Atomium employed one elevator, which ran through the vertical central tube and linked the entry pavilion with spheres #1, #3 (in the center of the design) and #9. The spheres atop the bipods were #2, #4 and #5, while the spheres “floating” in space and connected to the others via the horizontal and vertical tubes were #6, #7 and #8. In addition to the elevator, the building employed five escalators, which facilitated travel from the entry pavilion up into sphere #1, from sphere #1 to #2 and from sphere #2 to #3.

According to the 1961 EW article, the designers wanted to utilize escalators, because they felt the public should be able to “move from one sphere to the other without undue fatigue.” The article also stated that the desire to use this technology directly impacted the building’s form, as “this requirement determined the diameter of the tubes joining the spheres.” This fact suggests Waterkeyn and the Polak brothers may have imagined escalators traversing all of the Atomium’s diagonal tubes. However, in the end, only five escalators were employed, and only two of these operated in diagonal tubes.

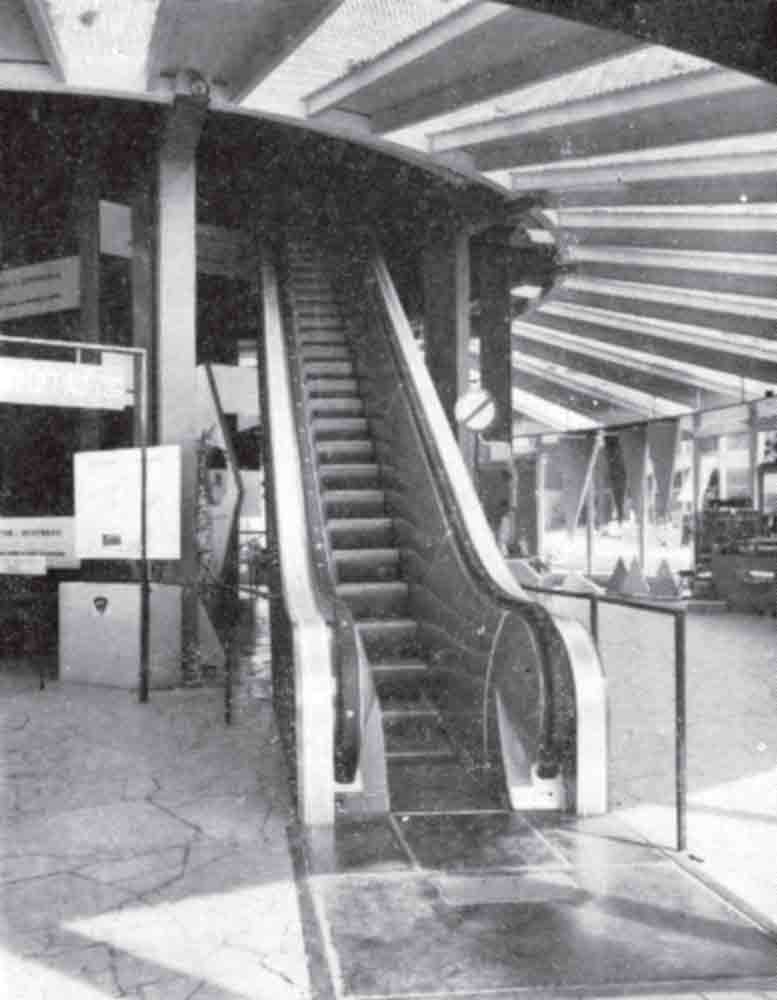

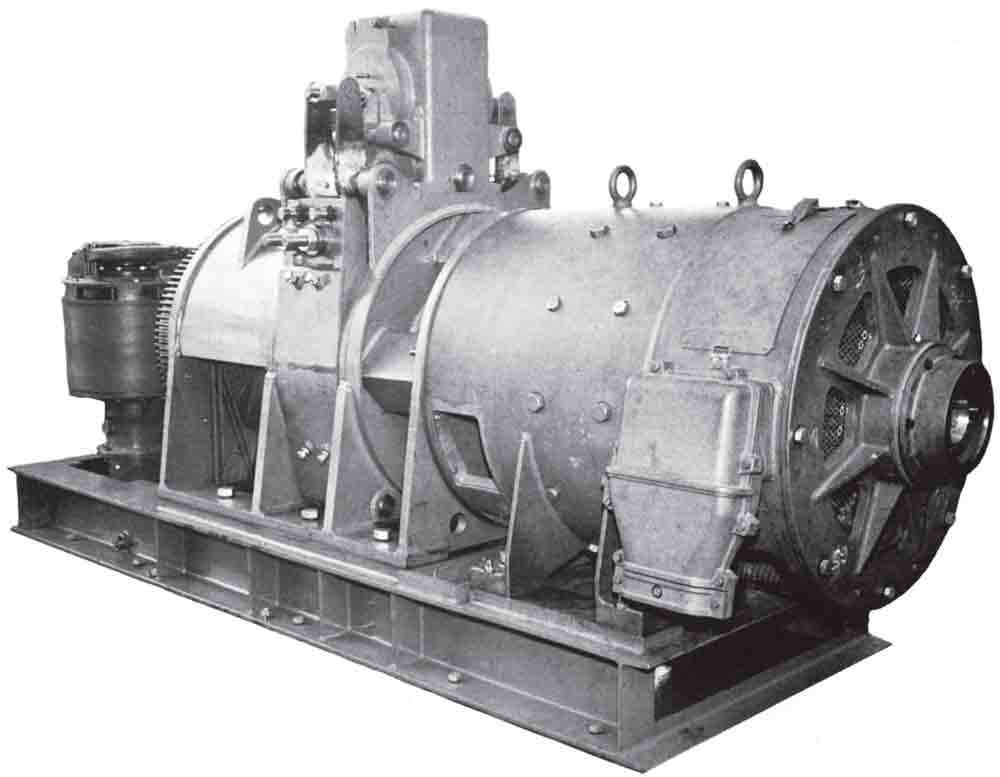

The escalator’s manufacturer contributed to the perception of the Atomium as “one of the most Belgian of all buildings,” which is how it is described in current Atomium promotional material. The escalators were designed and built by Ateliers Jaspar, located in Liège, Belgium. The company had been founded by electrical engineer Joseph Jaspar (1823-1899) in 1842, and throughout the 19th century, it manufactured electric lamps, dynamos and engines. Following Joseph Jaspar’s death, the firm’s leadership passed to his sons Jean-André (1850-1909) and Albert Jaspar (1876-1911), who expanded the product line in the early 20th century to include elevators. By the 1920s, the company was also building escalators: the quality and character of its early escalator work can still be experienced in the St. Anna Tunnel in Antwerp, Belgium (1932), which features four escalators with wooden treads. The company designed and built what may be termed three normative and two special escalators for the Atomium, each of which was assigned a “letter” designation (Table 1).

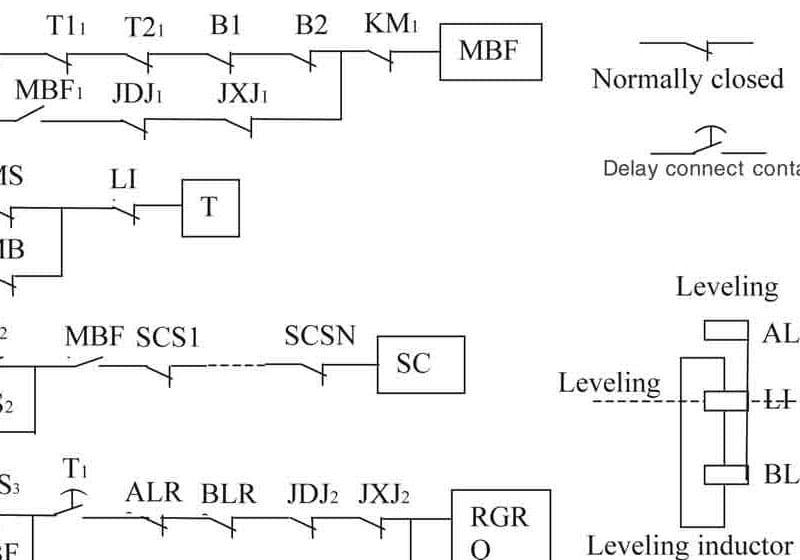

Ateliers Jaspar reported “nothing special to say about escalators A, B [and] D.” This was likely due to the fact that these escalators operated between the floors of the entry pavilion and/or within the spheres. The escalators designed to operate in the diagonal tubes connecting spheres #1 and #2, and #2 and #3 presented unique design challenges. The first was the anticipated movement the escalator trusses would encounter due to the Atomium’s unique structural system, which was described as an:

“. . . articulated steel frame; the principle of a ball-and-socket system had been applied to the junctions of the spheres and tubes, thus entailing a rotary motion between them giving rise in the most unfavorable circumstances to a displacement of approximately 1.279 in. in all directions at the supporting point of the escalators. In actual fact, the maximum displacement recorded was 14 in.”

To prevent excessive movement and “distortion of the truss. . . a system of level arms was placed between the structural girders of the spheres and the truss.”

The vertical rise of escalator C, the length of both C and E, and the restricted space of the tubes prompted a careful examination of the chain and handrail design, as well as concerns about the “strength of the roller rims at the changes of incline.” Ateliers Jaspar addressed the first issue by dividing the chain into equal load zones and employing “identical drive machines” in each zone (three for escalator C and two for escalator E). For both escalators, one drive was “placed at the top of the escalator in a conventional driving position,” and the other drives were placed “in the balustrades engaging the step chains tangentially.” The operation of the drive machines was “synchronized by a system of hydraulic couplings” to reduce the possibility of “engaging the chains in a ragged fashion and so communicating unpleasant jolts and vibrations to the steps and their passengers.” A “supporting caterpillar track assembly was fitted underneath the main chains directly beneath the main sprockets to prevent sagging and [ensure] chain control contact with the sprocket.”

Ateliers Jaspar found that the use of “equipotential zones in the chains” solved the roller rim problem. The company reported the synchronization of the handrails and steps “was secured by conventional means.” However, it also noted:

“Special research was undertaken. . . in order to improve contact between handrails and traction sheaves. A series of rollers rotating on ball bearings was inserted in the handrail to facilitate its movement.”

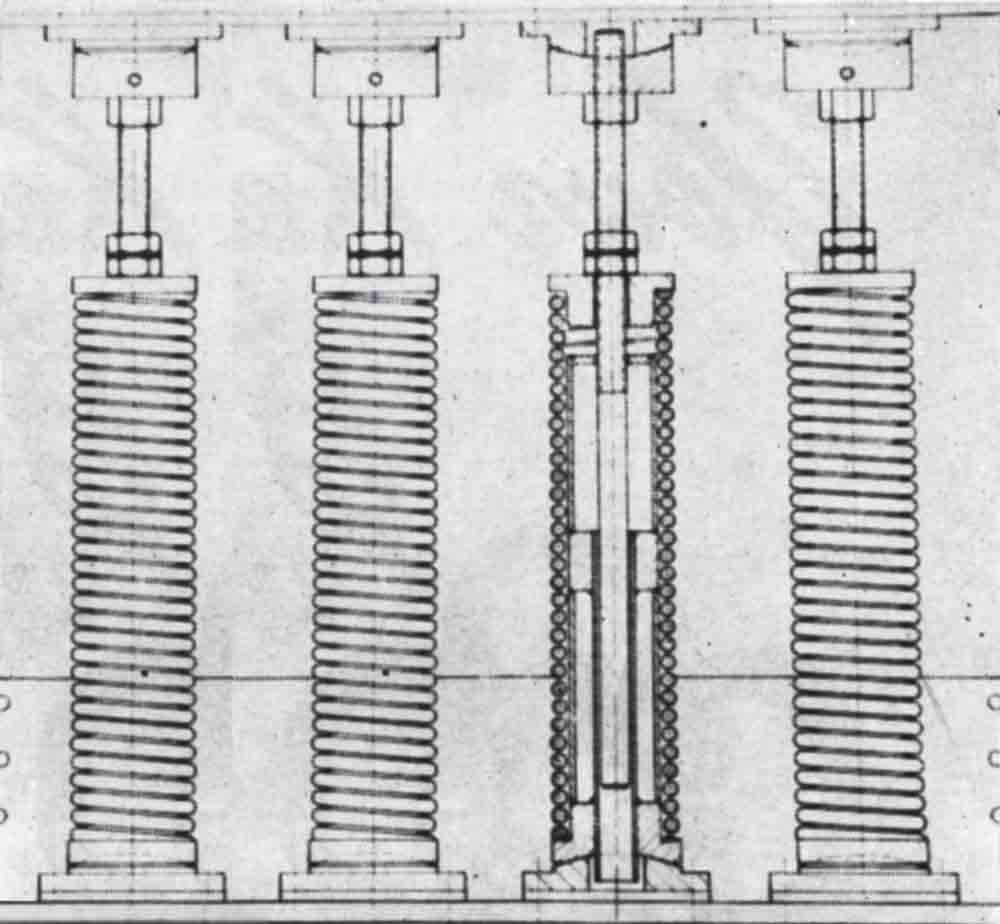

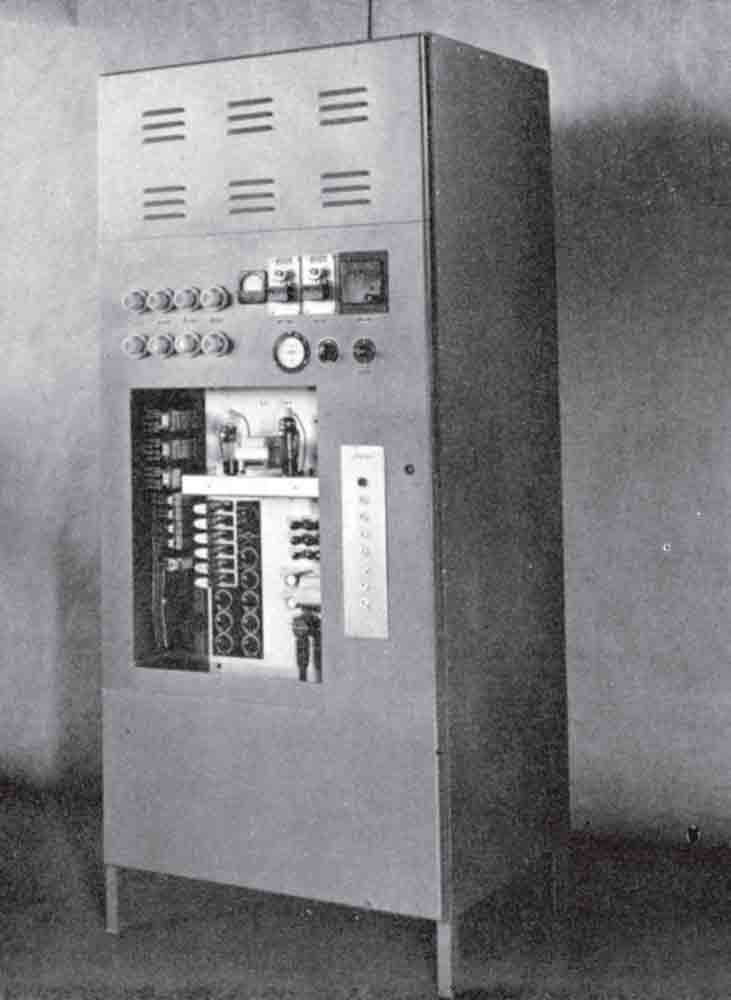

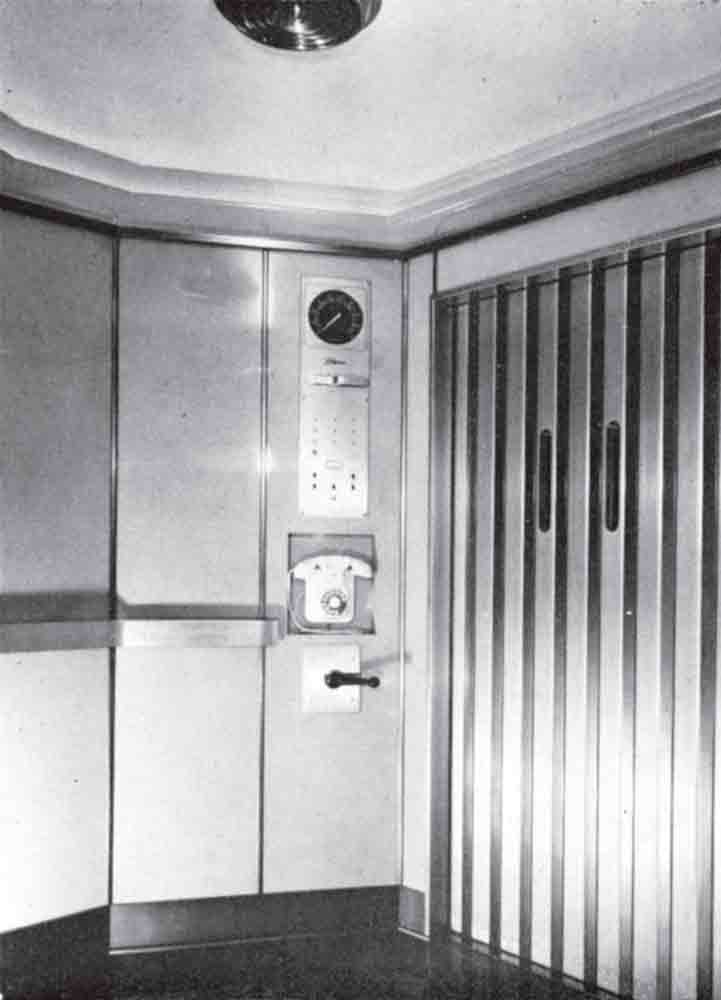

The Atomium’s elevator was designed and built by the Schweizerischen Waggon und Aufzügefabrik (Swiss Car and Elevator Manufacturing Co.) located in Schlieren, Switzerland. The company was founded in the 1890s as Schweizerische Wagonsfabrik AG and specialized in building train and trolley cars. It began building elevators in the 1920s, and in 1928, the name was changed to include the term aufzügefabrik (elevator manufacturer). The primary design challenge faced in designing the Atomium elevator was the small-diameter circular vertical shaft, which impacted door layout and the placement of the hoisting machine, motor-generator set and control unit. The company decided to separate these components – the hoisting machine was placed in sphere #9, the motor generator was placed in sphere #3, and the Variotron control unit was placed in the entry pavilion. The control unit featured Plexiglas® covers so the public could “view its function.”

The elevator had a rise of 300 ft., a capacity of 3300 lb. and made three stops: the entry pavilion, sphere #3 and sphere #9. It was driven by a double-wrapped gearless machine with 1:1 roping. It utilized variable-voltage control with “full feedback, stepless electronic control of the thyratrons supplying the generator field.” (The “thyratron” was introduced in the late 1920s and is a gas-filled, hot-cathode electron tube that functions as a type of high-energy electrical switch and controlled rectifier.) Other features included a geared emergency electric drive, which, along with the control circuits and door drive, was “fed from a separate source. . . in case the normal supply should fail”; “slow-down switches” that ensured the “program speed was not exceeded during the approach to the terminal landings”; and extra-long hydraulic buffers.

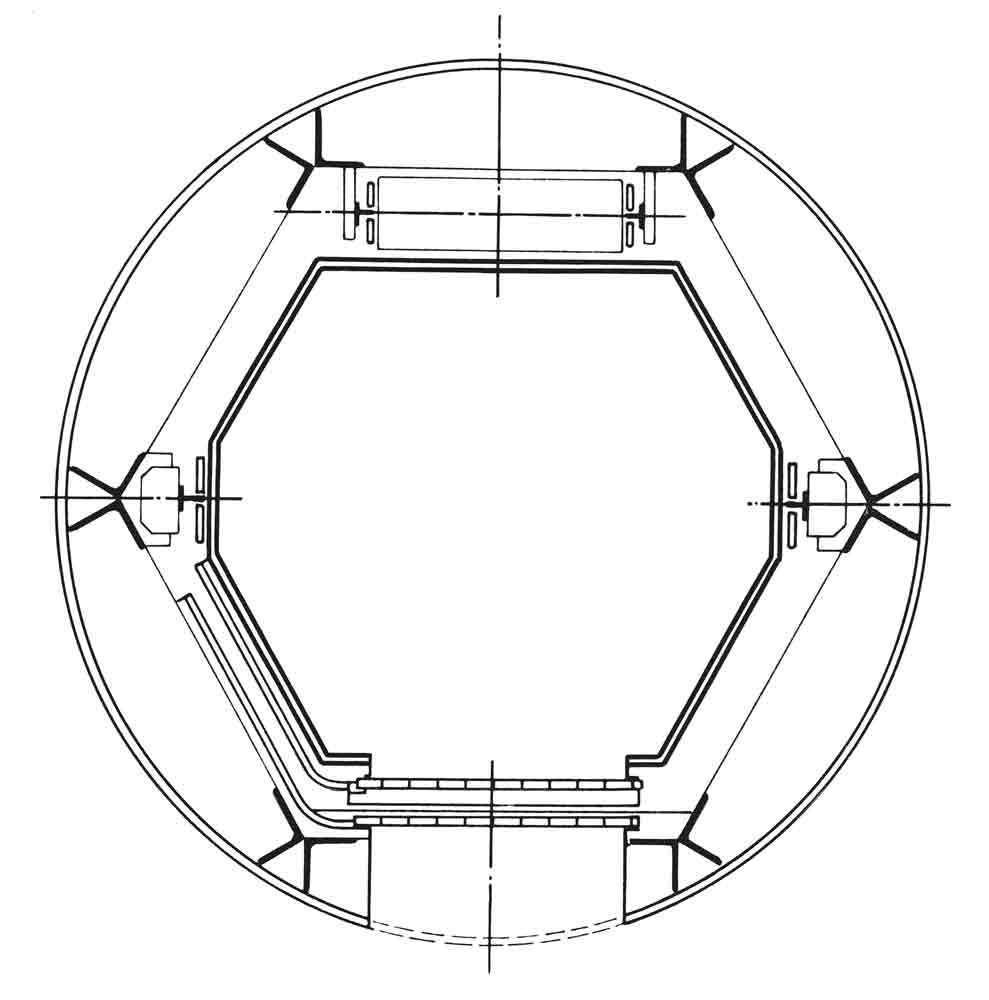

When the Atomium opened, its elevator was one of the fastest in Europe, operating at 1,000 fpm. The octagonal elevator car had a modernistic design that employed red panels with gold anodized light-alloy trim and featured indirect lighting, a fan, a telephone, an operator’s switch and a large-scale position indicator that allowed visitors to track the car’s progress through the shaft. To ensure a quiet and smooth ride, the car was equipped with “special insulation and roller guides.” The car and shaft utilized gold anodized aluminum “Portaflex” power-operated, multipanel doors fitted with small “vision panels.”

The Atomium offered visitors a unique experience that highlighted the excitement and potential of escalator and elevator travel in the mid 20th century. One can only imagine how visitors would have reacted if every tube had featured an escalator and the building had presented a total system of mechanized transportation. As completed, the five escalators only carried passengers up to the central sphere; to exit, visitors had to walk down the stairways. Nonetheless, the Atomium was a successful attraction and popular emblem of the 1958 Brussels Universal and International Exhibition. The building continues to be a key architectural attraction of the city and remains “one of the most Belgian of all buildings.”

Ateliers Jaspar, Atomium escalator A (entry pavilion)

Ateliers Jaspar, Atomium escalator C (connecting sphere #1 to sphere #2)

Ateliers Jaspar, Atomium escalator level arms schematic

Schweizerischen Waggon und Aufzügefabrik, Atomium elevator car (plan)

Schweizerischen Waggon und Aufzügefabrik, Atomium elevator gearless machine

Schweizerischen Waggon und Aufzügefabrik, Atomium elevator Variotron control unit

Table-1

Get more of Elevator World. Sign up for our free e-newsletter.