“Next-generation” system stands to decrease the total number of vertical-transportation units in tall buildings by 40%, is proposed for application in major projects.

by Fritz King, Lars Hesselgren, Peter Severin, Patrik Sveder, David Tonegran and Sirpa Salovaara

The Articulated Funiculator concept is a quantum leap in vertical transportation in tall buildings and deep underground subway stations. A connected system of “trains,” it involves a vertical sky subway that services sky lobbies and a system of pods that service individual floors (ELEVATOR WORLD, August and October 2013). One such system requires only two vertical shafts, which increases the percentage of usable floor space and the speed of passenger conveyance and has the potential to evacuate upper floors in tall buildings faster than current elevator systems.

The efficiency of the system is that many trains/pods share the same two shafts. This reduces the size of the elevator core and increases gross/net floor ratios by as much as 30% when compared to current high-rise buildings, which can have gross/net floor ratios as low as 60%. This negatively affects revenue potential. In addition, every conventional elevator requires its own shaft, tracks, cables and motors. This is inherently inefficient and costly. A reduction in the number of elevator shafts increases gross/net floor ratios and reduces construction costs.

Connected Trains

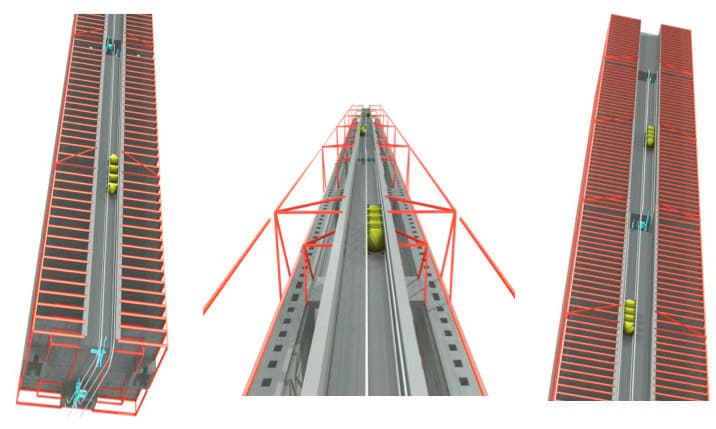

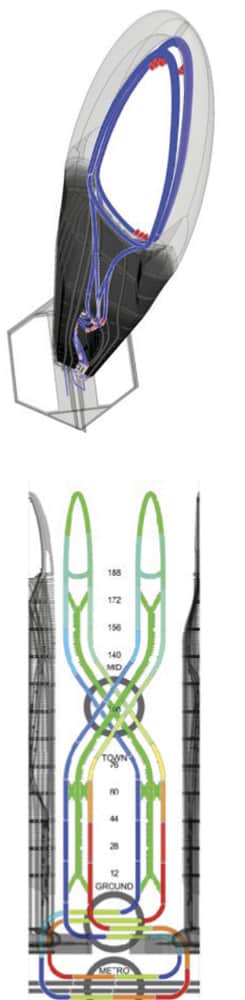

One development for the Articulated Funiculator is a continuous and connected system of high-speed “trains” that stop at Sky Lobby floor levels designated as “stations” (Figure 1).

The system stops at all up- and down-bound stations simultaneously, and intermediate floors (between stations) are serviced by individual pods or conventional elevators. A single Articulated Funiculator train can be fitted with one or more train cars depending on the vertical-transportation needs of the building. Most high-rise buildings with sky lobbies utilize double-deck conventional elevators to service these areas. A comparable Articulated Funiculator system would utilize two train cars per train. It is reasonable to equate such a train car to one conventional elevator, as they are equivalent in size and passenger capacity. The total number of vertical-transportation units with Articulated Funiculator trains that service sky lobbies and conventional elevators that service the floors between sky lobbies is less than the total number of vertical-transportation units of an all-conventional elevator system.[1]

The Articulated Funiculator has the potential to decrease the total number of vertical-transportation units in tall buildings by 40%. Another development it implements is individual pods that stop at every floor. In this capacity, they function as and replace all of the conventional elevators, therefore further increasing gross/net floor ratios. The development of the individual Articulated Funiculator pod systems is more complex than the connected train systems and requires traffic-management control systems to handle such variables as paths, location, speed, scheduling and traffic congestion. Pods will be banked at the bottom and top of a particular circulation loop and be dispatch controlled for maximum efficiency.

Vertical-Transportation Shafts — Fewer Is Better

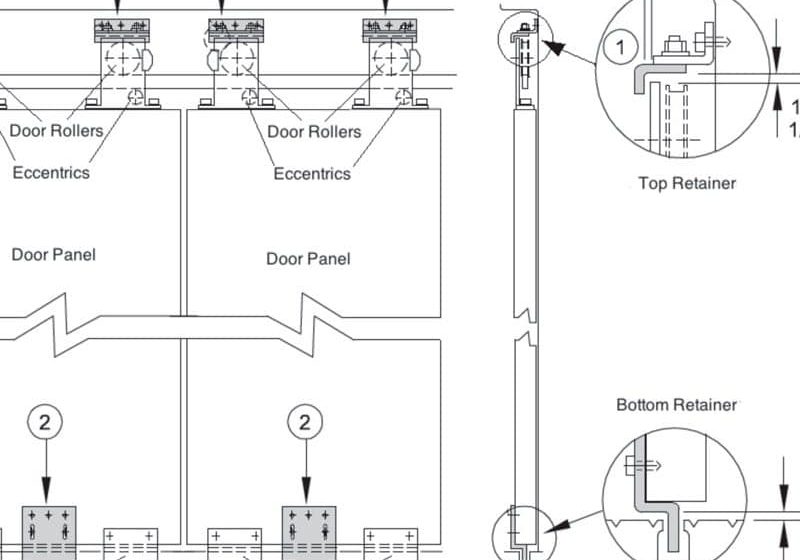

Current vertical-transportation technologies result in large elevator cores that consume large volumes of the building. The volume of space committed to elevators in high-rise buildings is enormous when added up along the length of the building. An efficient vertical-transportation system could swap this enormous waste of space for revenue-generating programs. A system requiring only two shafts drastically reduces the number of elevator shafts in tall buildings and underground facilities. In addition, the Articulated Funiculator can be fitted with doors on both sides of the train cars so passengers can exit as others enter. This will reduce loading/unloading times and increase passenger flow.

A drastic reduction in the number of vertical-transportation shafts has a major impact on high-rise building architecture, construction and densification. A smaller or nonexistent elevator core will reduce the required floor-plate dimensions, which will result in compacted and thinner high-rise buildings. This will, in turn, reduce the amount of façade material and other construction costs. Smaller floor plans will enable developers to situate more buildings on the same plot of land, which will increase their revenue.

System and Pod Design

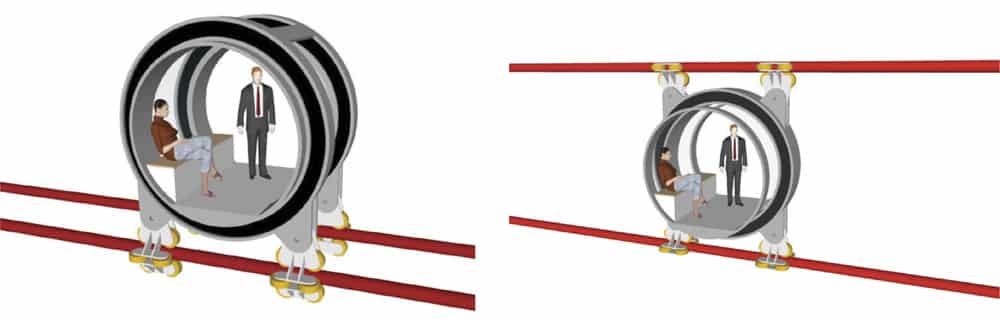

The Articulated Funiculator design is very flexible, offering vertical and horizontal alignments, slants, curves and twists. The system can be generic (for example, enclosed with straight vertical alignments) or expressive (for example, on the exterior of a shaped building). A generic pod offers a barebones design with one degree of rotational freedom. Because generic pods are enclosed inside shafts and not seen by the public, most of their designs neglect elegance and architectural expression, emphasizing mechanical efficiency and cost effectiveness (Figure 4).

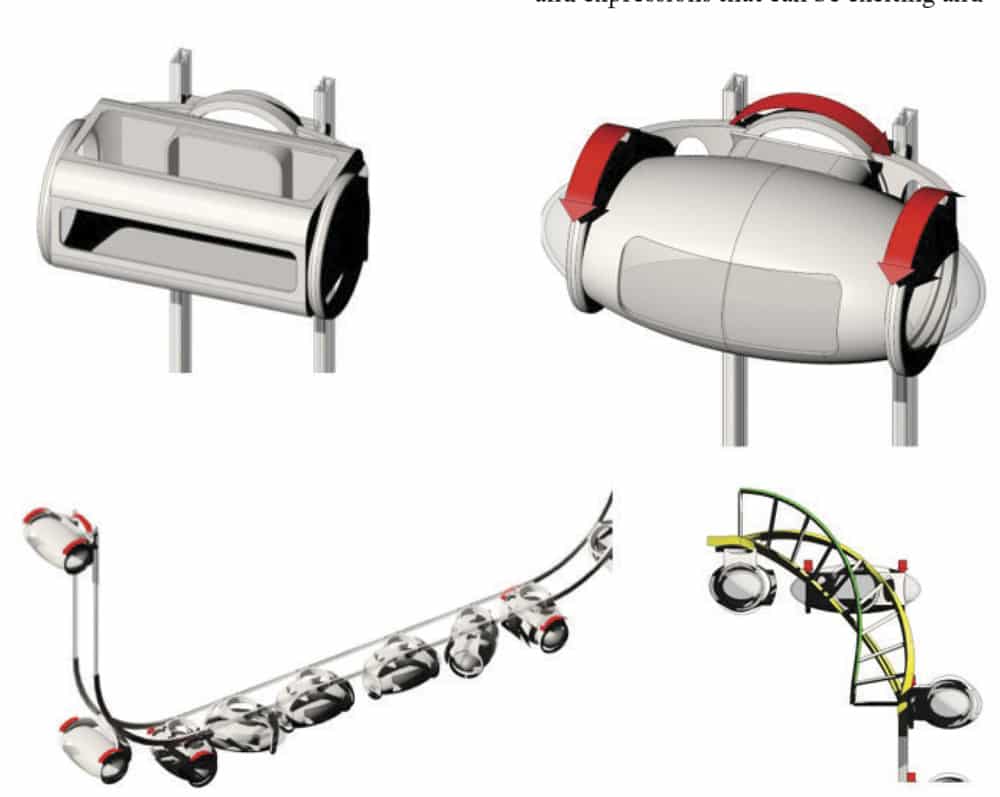

Vertical-transportation systems can be much more than machines to convey passengers. The Articulated Funiculator offers contributions to architectural shapes and expressions that can be exciting and innovative. The system can be visible and showcased as part of building architecture. Its shapes and alignments can add a fourth dimension to building architecture — dynamic architecture that moves. These pods emphasize elegance and architectural expression, and utilize two or three degrees of rotational freedom. They are also designed with windows and glass walls to enhance scenic views.

Case Studies

Stockholm Subway Stations

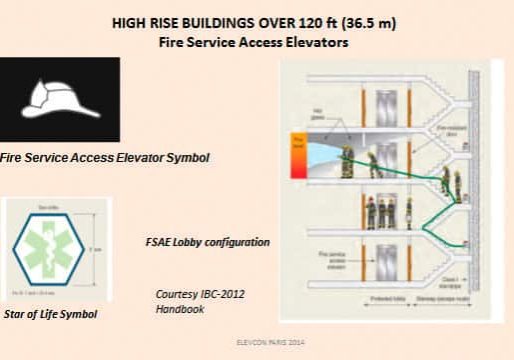

Stockholm Local Traffic (SL), owner of the subway system in Stockholm, Sweden, plans to extend its existing lines and construct new ones. The Nacka extension will have deep underground stations approximately 100 m below grade in hard granite rock. The vertical-transportation system will convey routine passengers and be required to evacuate two fully loaded subway trains within a limited timeframe.

The extreme depth renders escalators unfeasible, as passenger travel times would be on the order of several minutes. Using conventional elevators would require approximately 10 conventional elevators — five at each end of the station — and 10 associated shafts that will need to be blasted through hard granite. The subway provider, however, believes the Articulated Funiculator is a worthy alternative. This application of it would have two loops — one loop at each end of the station — with two shafts for each loop, giving a total of four shafts versus 10. This reduction in shafts would drastically lower excavation costs and construction time.

The proposal is to have two separated pod systems of two pods each in each loop, which gives a total of four pods per loop. While one system of pods loads and unloads passengers, the second pod system is in motion from and toward the next station. This enhances continuous and uninterrupted passenger flow (Figure 7).

The 888: Articulated Funiculator as a Building Expression

The Articulated Funiculator can also be utilized as a unique experience. One fundamental design decision for the system is its rotational degrees of freedom. Initial design studies indicate that, fundamentally, a system with three degrees of freedom is preferable, since it allows an enormous potential to adapt to different building configurations. Further examination indicates that the cabin requires only two degrees of freedom, while the third can be obtained by the track configuration. Critically, it means the track must allow helical-type paths with attendant torque in the path (Figure 8).

The Articulated Funiculator incorporates modern information technology to allow for complete “on-demand timetabling.” The system will know through mobile apps which users are approaching and require transport to their destinations. Waiting times for pods will be minimized, as the system will pre-allocate them to reduce wait times.

PLP/Architecture is contributing an extreme example of what can be achieved with the Articulated Funiculator through a proposed supertall skyscraper. Dubbed the “888,” the building is to be 888 m tall to the highest floor and be crowned with an Articulated Funiculator loop that stretches up to a height of 1000 m above the ground (Figure 9).

The building is divided into four segments: bottom, middle, top and crown. The top and bottom segments contain very large floor plates, and design studies are underway to explore a variety of ways those plates can be exploited. The middle section has a large hole through the building — a “Central Park” — around which are several hotels and high-value apartments (Figure 10).

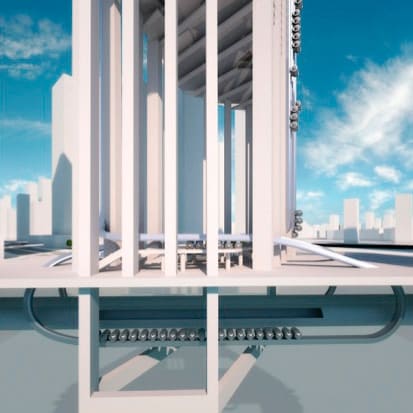

The systems envisaged for this tower will be both connected trains and individual pods in separated loops. The building is so large that it warrants its own metro/high-speed rail station located under it. High-speed Articulated Funiculator loops are integrated with the platform level, ground floor and metro station. As designed, passengers disembarking subways and trains can walk across the platform to catch a funiculator that will usher them to a sky lobby or floor (Figure 11). There are three loops for individual pods (each loop serving 96 floors) that have differing paths utilizing the vertical structure. Further studies will ascertain the capacities required of all the systems, but it appears likely that any limiting factor would primarily involve the number of pods available, rather than track capacity (Figure 12).

Conclusion

The Articulated Funiculator offers more than a means to convey people up and down a building. In applications such as the 888, where it would be 1,000 m in the air, people would come to ride system as an attraction all its own, much like the London Eye in London. The Articulated Funiculator offers new and efficient solutions for today’s high-rise buildings and deep subway stations. The reality of urban densification demands this quantum leap in vertical transportation.

Figure 1

Figure 2

Figure 3: Floor plans and shaft counts with the Articulated Funiculator

Figure 4: (l-r) Generic pods, side-by-side tracks and over-and-under tracks, providing one degree of rotational freedom.

Figure 5: Articulated Funiculator pods, providing two or three degrees of rotational freedom.

Figure 6: Proposed SL deep underground subway station isometrics

Figure 7: SL deep underground subway stations: proposed double-pod system

Figure 8: Pods with three degrees of freedom

Figure 10: The 888’s (clockwise from top left) bottom, middle, top and crown segments

Figure 11: The 888’s metro/funiculator station

Figure 12: Funiculator looping in the 888

Figure 13: The Articulated Funiculator promotes new architectural programs, such as a “grand atrium,” in designs for the 888.

References

[1] Ericsson-Lantz, C. and Skröder, E. “The Articulated Funiculators Potential to Evacuate High-Rise Buildings,” Luleå University of Technology, 2013 (pure.ltu.se/portal/files/44158502/LTU-EX-2013-44006091.pdf).

Get more of Elevator World. Sign up for our free e-newsletter.