Study shows hydraulic lifts have a lighter environmental footprint than traction lifts for some uses.

This paper was presented at  Berlin 2018, the International Congress on Vertical Transportation Technologies, and first published in IAEE book Elevator Technology 22, edited by A. Lustig. It is a reprint with permission from the International Association of Elevator Engineers

Berlin 2018, the International Congress on Vertical Transportation Technologies, and first published in IAEE book Elevator Technology 22, edited by A. Lustig. It is a reprint with permission from the International Association of Elevator Engineers  (www.elevcon.com).

(www.elevcon.com).

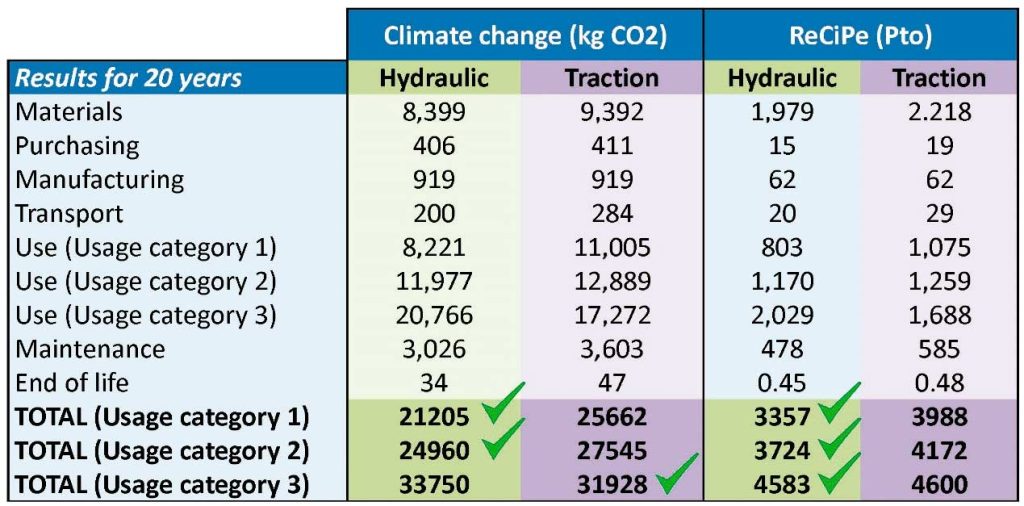

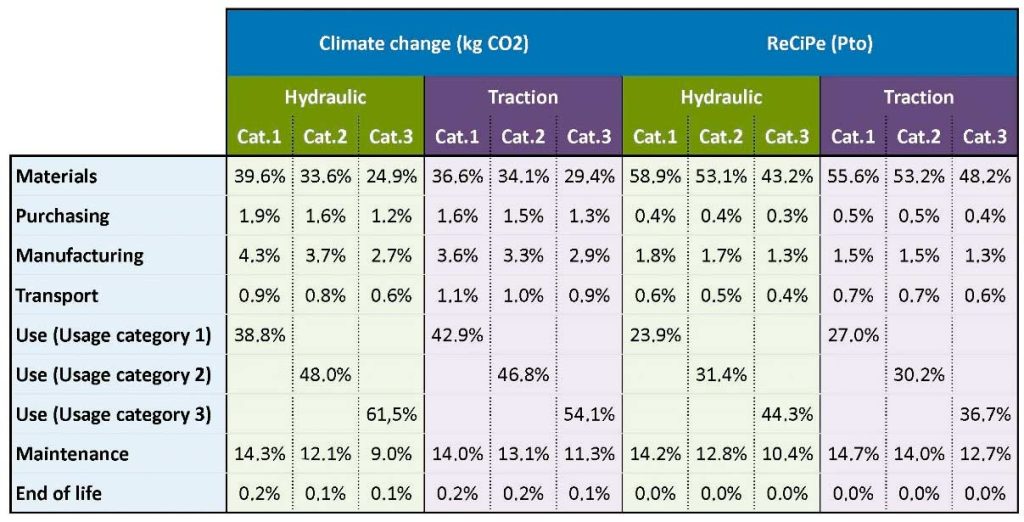

The European Lift & Lift Component Association (ELCA) asked the ITAINNOVA laboratory of Saragossa University in Aragon, Spain, to do a series of life-cycle assessments (LCAs) of both hydraulic and traction lifts and compare the results obtained, in terms of environmental impact. ITAINNOVA collected data on recent generations of both types of lifts and compiled them for comparison. The calculation method used CML-IA, baseline EU25 and ReCiPe as recommended by the Product Category Rules (PCR) draft for lifts (Environdec). The LCA software used was SimPro 8.0.3. The database implemented in this software is Ecoinvent v3.1. Environmental-impact categories included in the study are climate change: kgCO2e and ReCiPe: Pt (points). The results show that hydraulic lifts have a lighter environmental footprint than traction lifts for usage categories 1 and 2 (50 and 125 trips/day) and partly for category 3 (300 trips/day) during the first 20 years. Traction lifts have a better environmental performance for usage category 3 (over a 20-year lifespan) and higher.

Initiative

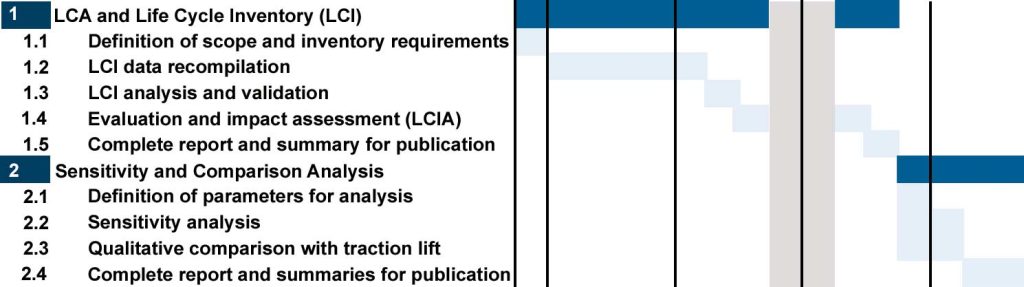

In 2014, an ELCA Working Group launched a study, to be done by ITAINNOVA, comparing LCAs of both the most recent generations of traction and hydraulic lifts for the first time. The life cycle considered was 20 years, though the average lifetime of lifts in Europe is closer to 50 years. The study was initiated in parallel with the publication of the PCR Lifts, to which ELCA members (GMV, Blain, Hydroware) actively contributed. PCR Lifts was published in October 2015.

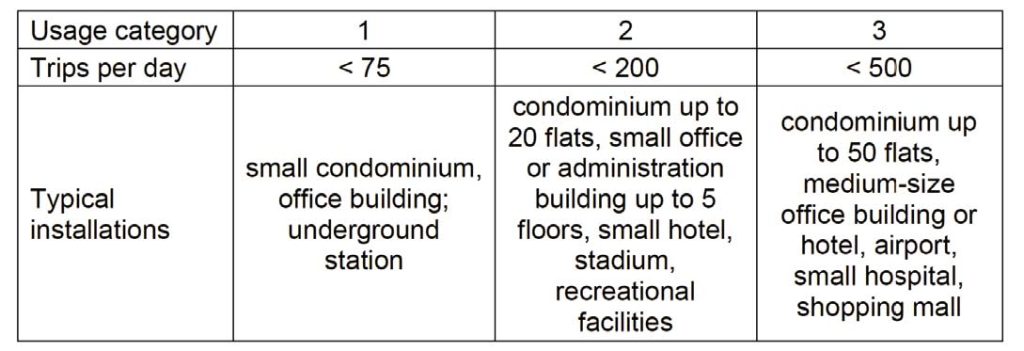

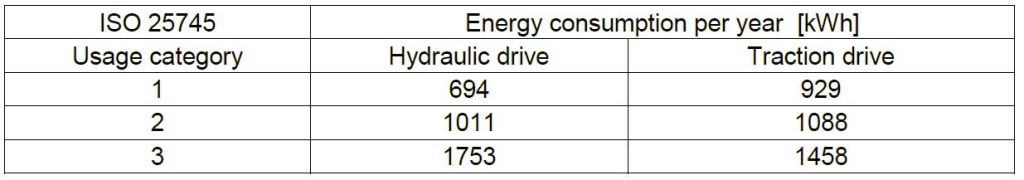

ITAINNOVA’s mission was to analyze the life-cycle inventory (LCI) of a series of lifts in usage categories 1, 2 and 3 (as defined in ISO 25745-II) over 20 years using the methods of the climate- change system (kgC02) and the EcoIndicator (ReCiPe).

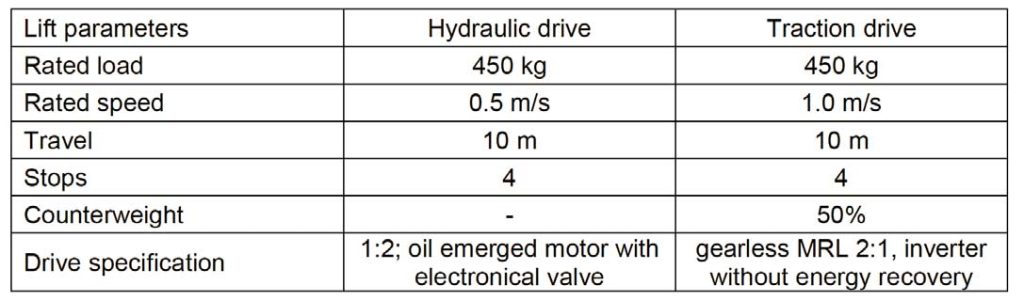

Lift Definition

interventions or modernizations are needed

UsageType

Hydraulic and Traction Lifts

European policies strongly focus on the reduction of energy consumption, increased efficiency and sustainability. A lift has a long lifetime. It is installed for a minimum of 20 years, and the total lifespan often reaches 50 years and more. Production, repair, maintenance and modernization have, therefore, a significant impact on the environmental footprint of the lift.

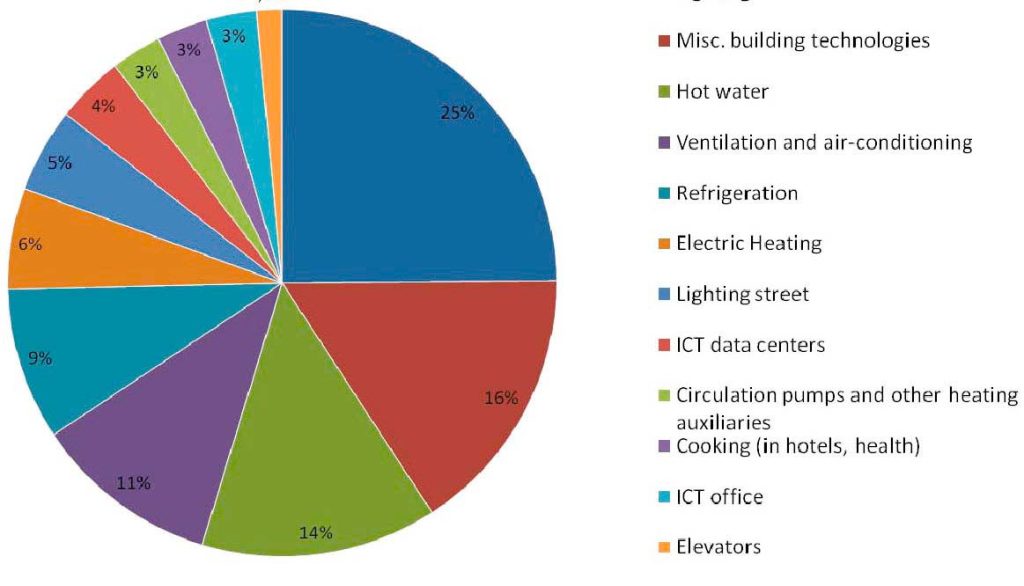

A lift is a means of transportation. It implies comfort, full accessibility and reliability/safety in the transportation of people and goods. The lift optimizes the usage of a building and its value. Energy consumption comes after these priorities and must be looked at in the context of the full life cycle of the lift, not simply the electricity consumption during standby and use.

The energy consumption of a modern lift in a five-stop residential building is basically very low, around EUR170 (US$192) per year. Overall, the standby consumption is higher than the energy consumed during use of the lift.

Previously, misleading campaigns about the environmental performance of hydraulic lifts have been led. It transpires, for example, in some International Organization for Standardization (ISO) documents and in the 2010 German AMEV instructions Hinweise für Planung, Ausschreibung & Betrieb von Aufzugsanlagen in öffentlichen Gebäuden (Indications for Planning, Tendering & Operation of Elevator Systems in Public Buildings to Civil Servants Launching Calls for Tender for New Lifts in German Public Buildings). AMEV requested justification for the use of any hydraulic lift in public tenders. This practical exclusion of hydraulic lifts from public buildings in Germany was based on wrong conclusions, notably in the 2010 E4 study that only took energy use during functioning into consideration.

Examples in the AMEV document:

“2.2.3 For reasons of environmental protection. . ., hydraulic lifts will only be installed in exceptional and well-explained cases. .. . 2.5 Traction lifts have mostly advantages over hydraulic lifts. . . .4.3.1 Depending on the field of application, electric traction lifts will be preferred for new installations (gearless, with traction sheave and frequency control). Hydraulic lifts will only be installed in exceptional cases with very good reasons to do so.”

Since then, ELCA and VDMA (German mechanical engineering association) have stated that all unfounded instructions have been taken out of the latest version of the AMEV document.

Scope of the Study

The scope of the study was:

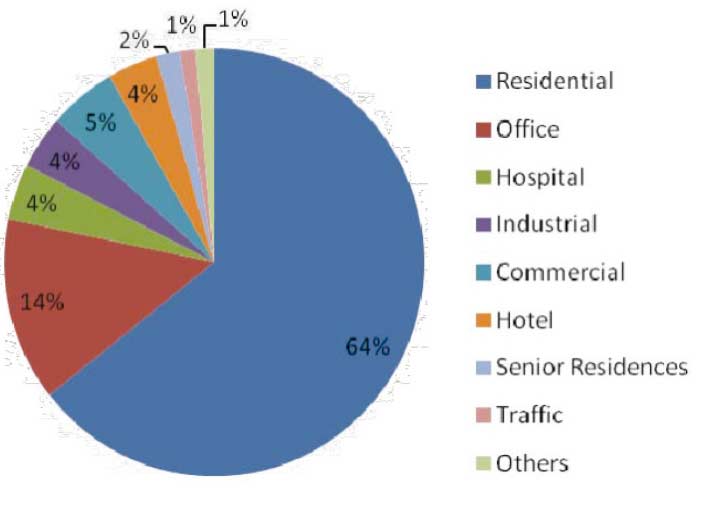

- Collecting data and producing LCAs for medium-travel lifts, which represent some 80% of the European new lifts market, using present-day technology

- Comparing hydraulic lifts and gearless machine-room-less (MRL) traction lifts in usage categories 1, 2 and 3 (ISO 25745)

- Analyzing new installations and modernizations, and comparing a full replacement and a partial modernization

- Analyzing the advantages of each drive technology with supporting data

- Developing an LCA as basis for an Environmental Product Declaration (EPD) that could become a joint project

- Analyzing the PCR impact on LCA

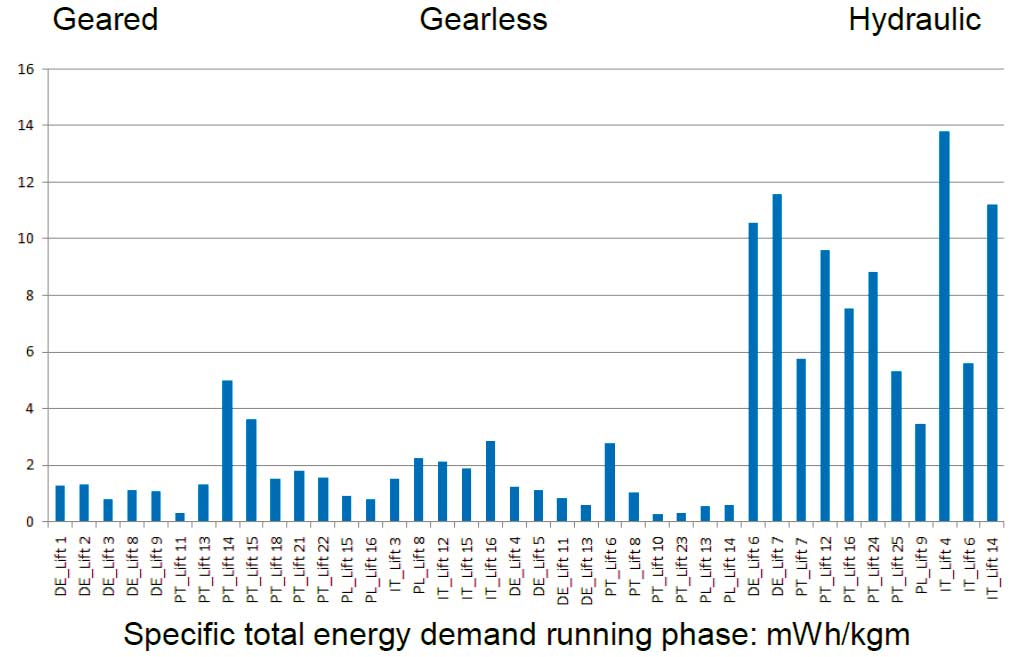

Figure 2 from the E4 report only presents the running energy consumption of measured older installed lifts. The conclusion was that hydraulic lifts are, in general, energy inefficient.

LCI

The phases for LCI are:

- Materials

- Transports

- Manufacturing

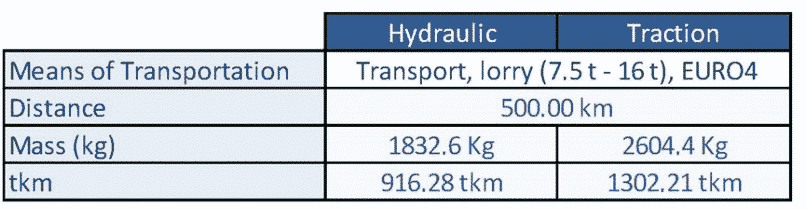

- Distribution

- Use

- End of life

LCA and LCI

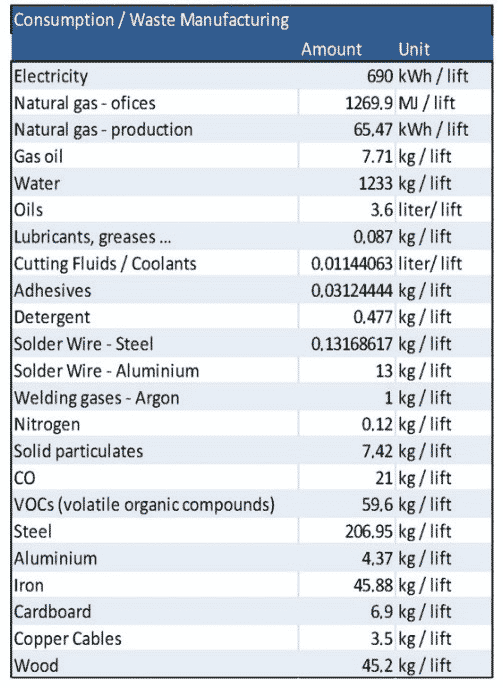

The LCI takes all raw materials into account, influencing the result. An important parameter in the manufacturing phase is the dedicated energy, such as the energy used for welding on the cabin or doors, for example. For transportation and distribution, delivery distances influence the result. The usage phase (mainly, energy consumption and maintenance) is one of the crucial phases influencing the LCA result. The Union for the Coordination of the Transmission of Electricity (UCTE) electricity mix is applied in the study.

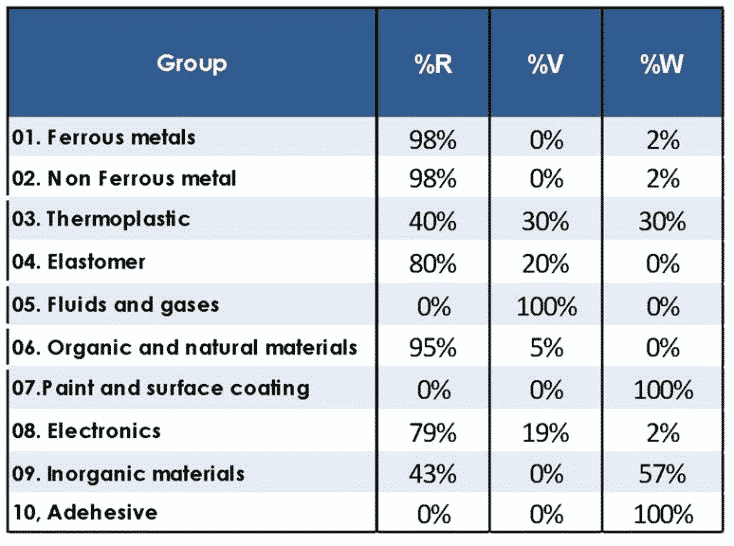

Dismantling and recycling have less impact, thanks to a high rate of recyclability of the materials used.

An LCA takes time. ITAINNOVA collected data for a series of lifts, including both installations and modernizations. The collection of useful data is a long process and includes measurements, analysis of purchasing and consumption data, and obtaining data from suppliers and sub-suppliers, etc.

Material Phase

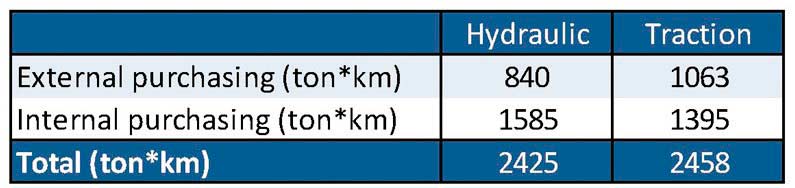

Purchasing Phase

a unit of an average lift . External purchasing equals raw material

transportation to manufacturing facilities; internal purchasing

equals processed material transportation to the installation site.

Manufacturing Phase

Distribution Phase

Use Phase

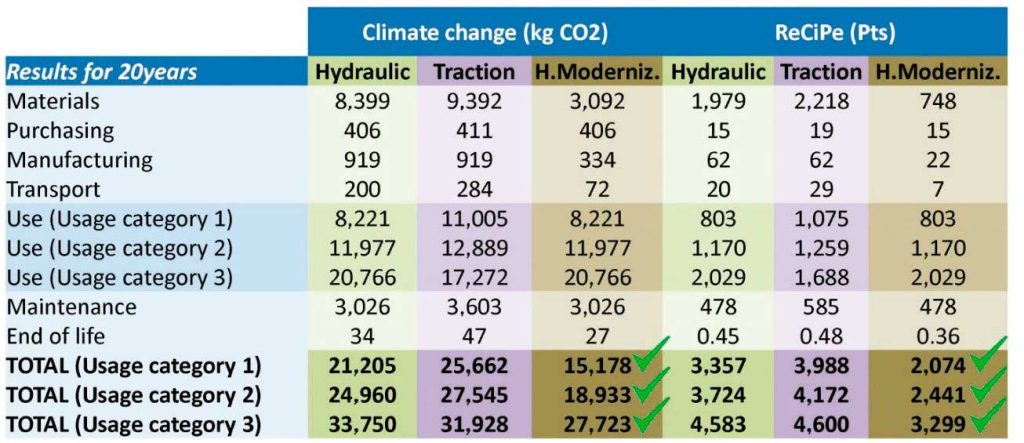

The higher amount of energy consumed by hydraulic lifts during use only starts to impact the general performance of the lift negatively (as compared to a traction lift) in usage category 3 (300 trips/day) (Table 3).

Maintenance Phase

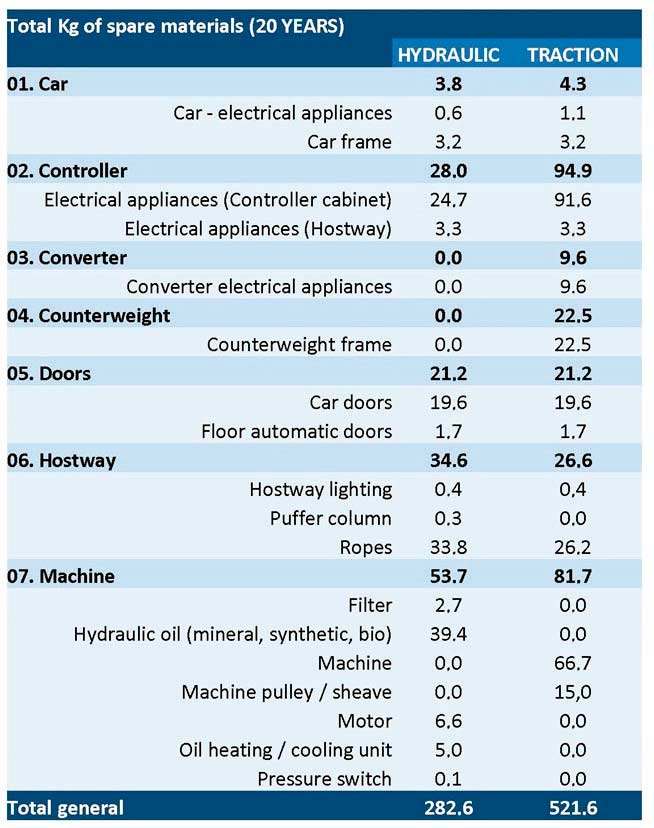

Table 4 indicates the average quantity of spare-part materials (in kilograms) used for the 20-year lifespan envisaged in the study. 6,000 km of technicians’ travel have been considered for both kinds of lifts (e.g., 10 interventions of 30 km/year or five interventions of 60 km/year).

End-of-Life Phase

Environmental Impact

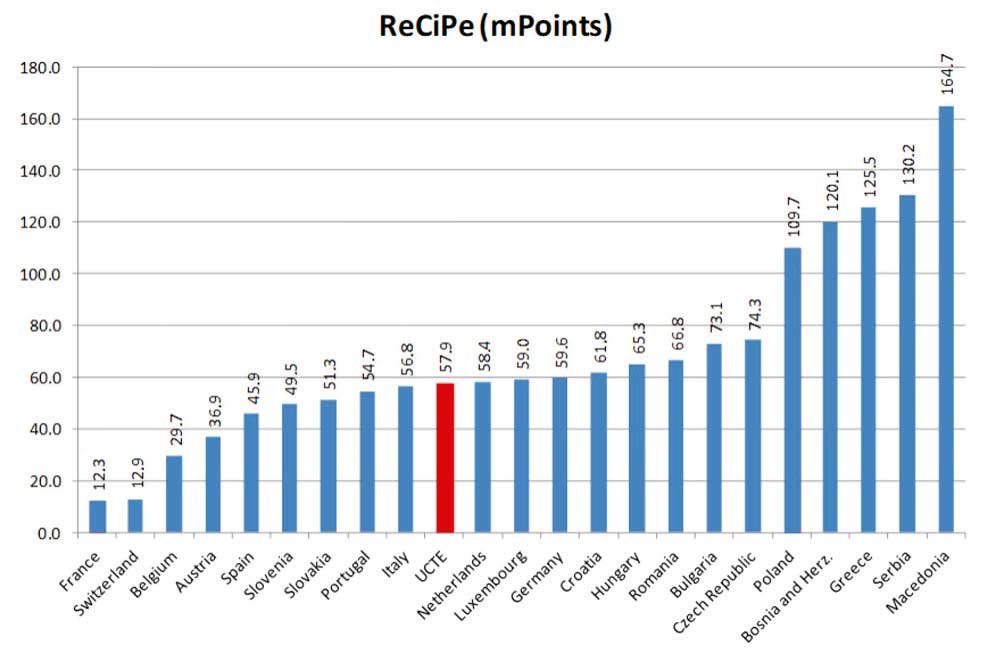

For the environmental-impact assessment, the electricity mix produced and used (including imports and their origin) by the country considered has an impact. Poland burns coal, so its power plants emit a lot of CO2. This gives much worse results than France, best in class because of the very low CO2 it emits. (Nuclear energy is the largest source of electricity in France and does not emit CO2.) Apart from nuclear energy, the more renewable the energy source, the less important is the energy used in the result of the environmental impact of the lift. ITAINNOVA used the average value of energy producers in Europe for the electricity mix in this study: the UCTE.

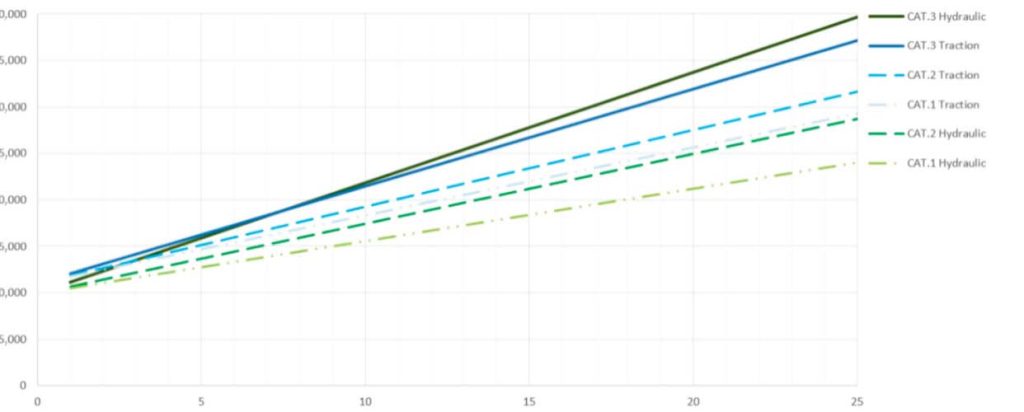

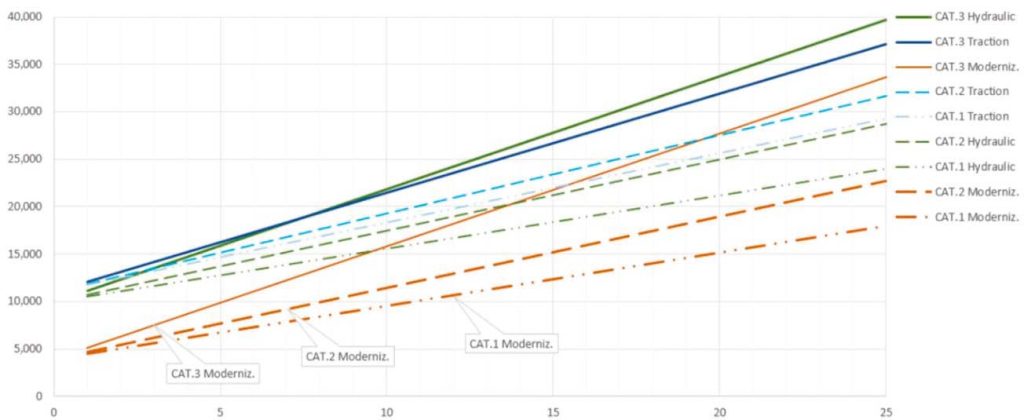

Climate-Change Indicator

Under the consideration of this study and for the impact category of climate change (Figure 5), results for hydraulic lifts are always lower in total environmental impact for usage categories 1 and 2. The longer the lifespan, the larger the positive difference for hydraulic lifts. In the case of usage category 3, a breakpoint in years (seven to eight) of use exists. Up to this point, the total impact of hydraulic lifts is also lower in climate-change terms.

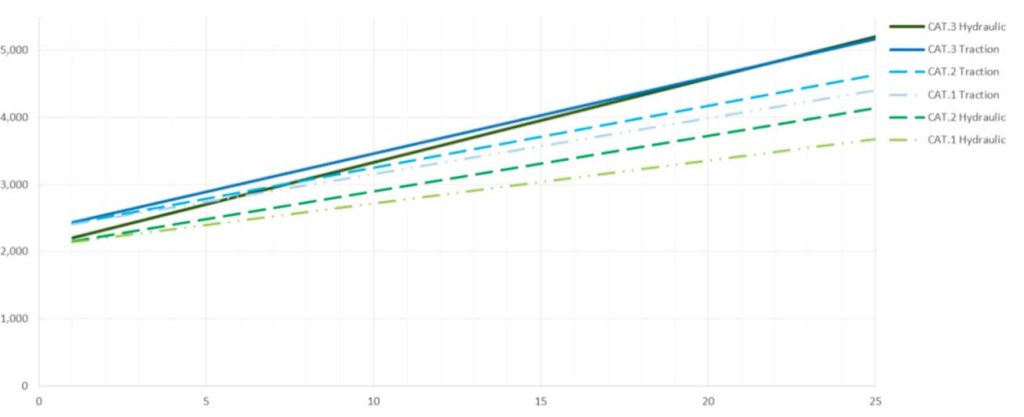

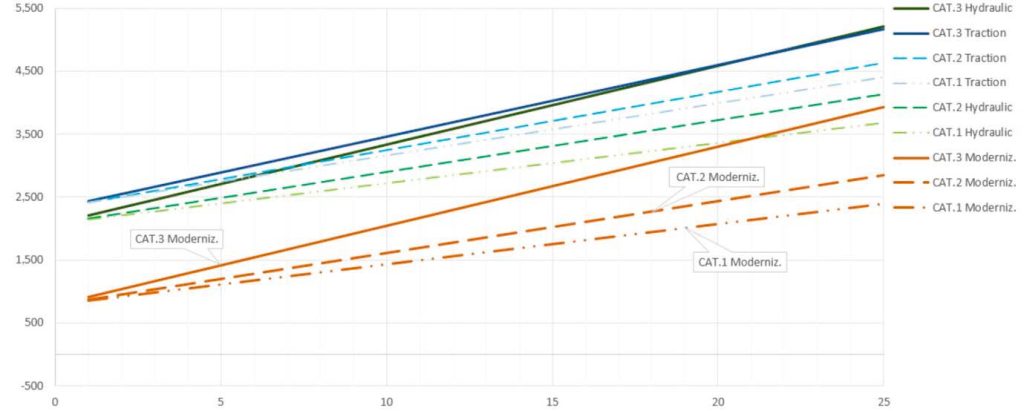

Ecoindicator ReCiPe

Under the considerations of this study and for ReCiPe (Figure 6), results for hydraulic lifts are always lower in total environmental impact for usage categories 1 and 2. The longer the lifespan, the larger the positive difference for hydraulic lifts. In the case of usage category 3, a breakpoint in years (21-22) of use exists. Up to this point, the total impact of hydraulic lifts is also lower in ReCiPe terms.

Interpretation of the Breakpoint Results

Under the considerations of this study and for both the impact categories of climate change and ReCiPe, results for hydraulic lifts for usage categories 1 and 2 are always lower (better) in total environmental impact. The longer the lifespan, the greater the positive difference for hydraulic lifts.

A breakpoint in years exists in the case of usage category 3. This is around seven to eight years of use, up to which the total impact for hydraulic lifts is also lower in climate-change terms. However, in ReCiPe terms, this breakpoint is around 21-22 years of use.

On one hand, differences between both results are given by the different impact considerations in the calculation criteria. Climate change, a single-effect impact category, is attending only to aspects related with the production of greenhouse gases, while ReCiPe is additionally attending (and with normalization and standardization criteria) up to 18 impact categories, all with a single resulting value. None is correct or incorrect. Both are different approximations of the problem. Therefore, the conclusion should be that a breakpoint exists between the better technology from the LCA perspective for usage category 3. And, this breakpoint can be within the range of the product lifespan, depending on the specific conditions of any case and on the data used for the study. These data include not only data from the product, but also from the calculation criteria or geographical considerations.

On the other hand, the change in trend in the range of daily travels around usage categories 2 and 3 is given by the differences between energy demands in standby or travel conditions for both technologies. In the data collected for this study, hydraulic lifts have a lower consumption during standby time than traction lifts do, while traction lifts have lower consumption during travels. It means that the longer the daily standby time, the relatively lower one is the total energy consumption for hydraulic lifts. In reverse, the higher the daily number of travels, the relatively lower the total consumption for traction lifts. That is the reason a breakpoint appears for category 3 but not for category 2, because there is a compensation of both types of energy consumption in an intermediate number of daily travels for both.

Final Conclusions: Comparing Hydraulic and Traction Lifts

With the data inventoried for the study and the assessment assumptions applied for the general inventories and calculations, the following conclusions can be extracted:

- Hydraulic lifts have less impact in the initial phases (mainly, materials and transportation), always resulting in a product with a better (lower) environmental profile in a “cradle-to-gate” approach (without including the service period).

- Hydraulic lifts have a better profile for those categories in which the use is not very intense, resulting in a better global option for usage categories 1 and 2.

- Traction lifts have a higher impact in the initial phases and a worse profile in the service phases (energy consumption) for usage categories 1 & 2. For more intense usages (categories 3 and higher), the lower energy consumption during service tends to compensate for the initial higher impacts, resulting in a lower general environmental profile for installations for 300-plus daily trips. For category 3, hydraulic lifts could be an even better option for special cases with a shorter-than-usual lifespan.

- Different results and conclusions might be obtained for the analyzed configurations if a different electricity mix is applied.

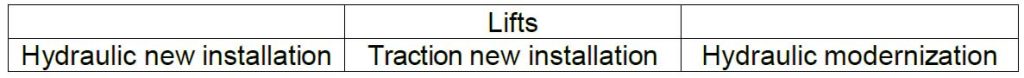

Modernization

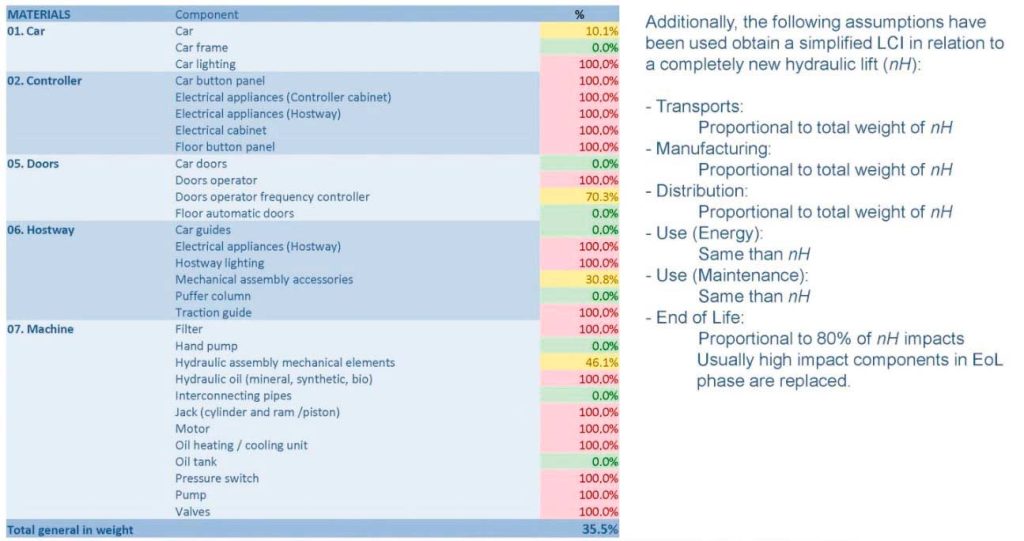

After 20 years, modernization of a hydraulic lift is compared to a full replacement in the existing lift shaft. Only the environmental impact is taken into consideration. Other variables, such as a state-of-the-art safety, size of the cabin, use change and modernity are not considered.

Simplified Inventory

Environmental Impact

Climate Change Indicator

Under the considerations of this study and for the impact category of climate change (Figure 7), for usage categories 1, 2 and 3, results for modernization of hydraulic lifts are always lower (better) in total environmental impact than for any other new lift with similar characteristics. For categories 1 and 2, the longer the lifespan, the larger is the positive difference for the modernization.

In the case of usage category 3, a breakpoint in years could exist but is expected to occur far in the lifespan of the modernized lift.

EcoIndicator ReCiPe

Under the consideration of this study and for the impact category of ReCiPe (Figure 8), results for modernization of hydraulic lifts for usage categories 1, 2 and 3 are always lower (better) in total environmental impact than any other new lift with similar characteristics. For categories 1 and 2, the longer the lifespan, the larger the positive difference for the modernization. In usage category 3, a breakpoint in year could exist but is expected to occur far into the lifespan of the modernized lift.

Summary of Results

Energy consumption in running and standby phases is one of the most important factors. The longer the lifespan, the more important the total impact. Therefore, the type of energy is important in the calculation of the total impact. Maintenance and raw materials are the second-most-important factors when using the evaluation of the present PCR Lifts rules.

An LCA is the only real analysis of the environmental impact and sustainability of lifts. The LCA evaluation is complete and gives a clear view of the full environmental impact of the installed lift. Energy consumption during use is only a part of the total picture, even if it is an important one. Costs and efforts put into data collection and the preparation of an LCA, and even an EPD, are high. For small and medium-sized enterprises, the cost is perceived as prohibitive.

In calls for tender, LCAs are not in demand today in Europe. This doesn’t look to change quickly. LCAs demonstrate that the modern hydraulic lift is the perfect option and is more sustainable for residential and, in general, all low-rise buildings with relatively low traffic.

For high travel and higher traffic, traction lifts are the better solution, with a lower environmental impact, including energy consumption.

A well-thought-out modernization is more sustainable than the complete replacement by a new lift in the same shaft. This is circular economy at work.

Acknowledgements

Several companies in Germany, Greece, Italy, Spain and Sweden co-financed the study that was finalized at the end of 2017. We thank ITAINNOVA Project Manager Carlos Peribanez for it. ITAINNOVA, the technology center at the university of Saragossa, is experienced in LCAs and efficiency-related topics. ITAINNOVA laboratories monitor new technologies, such as robotics and automation, and are familiar with the automotive and lift industries.

Get more of Elevator World. Sign up for our free e-newsletter.