Keeping up with codes governing the North American elevator industry can be exhausting but is always necessary, this Readers Platform explains.

by Jim Runyan

I always marvel at how we can build structures of immense size with intricate inner workings, considering the complexity of safety standards that rule their construction. When we consider just one facet of building construction, elevators, one can see it takes multiple standards just to ensure a code-compliant installation. The following list of North American standards comes to mind (and this is just the short list!):

- ASME A17.1/CSA B44 Safety Code for Elevators and Escalators

- ASME A17.7/CSA B44.7 Performance-Based Safety Code for Elevators and Escalators

- ASME A17.6 Standard for Elevator Suspension, Compensation and Governor Systems

- ASME A18.1 Safety Code for Platform Lifts and Stairway Chairlifts (CSA B355 in Canada)

- CSA B44.1/ASME A17.5 Elevator and Escalator Electrical Equipment

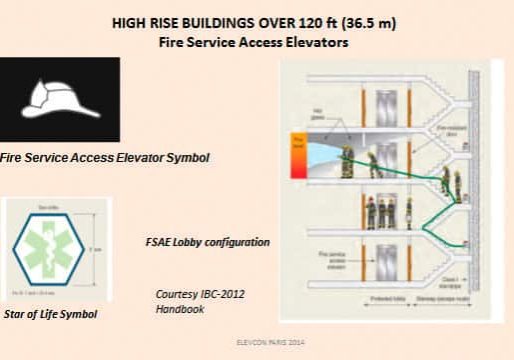

- NFPA 13: Standard for the Installation of Sprinkler Systems

- NFPA 70: National Electrical Code (CSA C22.1 in Canada)

- NFPA 72: National Fire Alarm and Signaling Code

- NFPA 101: Life Safety Code

- International Building Code (National Building Code of Canada in Canada)

- Compliance with various other American Society of Mechanical Engineers (ASME), ASTM International, Canadian, International Organization for Standardization, International Code Council and American National Standards Institute standards

- Listing/certification standards for components by testing labs

- Statutes, rules, and local/AHJ requirements

Looking at A17.1/B44 Part 9 gives one a sense of many other standards that are referenced in this standard. Certainly not all pertain to the physical installation of an elevator, but they must be verified at time of inspection to ensure a code-compliant conveyance.

So, I ask you: is it necessary to be educated in these standards? The obvious answer is, “Yes!” An inspector’s knowledge is challenged more today than ever before, and it keeps getting more complicated as time moves forward. An inspector must have a good understanding of the big picture and of the standards (or parts thereof) that make up an elevator installation. Now, it may not be necessary to know every chapter and verse of every code, but those sections relevant to elevators and escalators are certainly appropriate.

The tough part is that the standards are not the same across the country.

While NAESA International is in the business of providing education for inspectors and industry personnel, there are many avenues by which to gain education. State and local jurisdictions, ASME, and manufacturers (to name a few) often provide training for interested parties to better clarify the standards that govern elevator and escalator installations.

The tough part is that the standards are not the same across the country. Each state has its own list of statutes dictating which types of equipment are to be governed under an elevator safety program. In addition, not every jurisdiction is on the same edition of these standards. Inspectors doing inspections in multiple jurisdictions have the added challenge of knowing which rules to apply in which jurisdiction.

I look at my own background and note that even after 43-plus years in the industry, there is still a great deal to learn and understand.

Having a good grasp on the “big picture” is a daunting task and a constant challenge for inspectors to keep current with the latest standards as they are adopted and enforced. Knowing how to apply the code correctly with the right interpretation is a constant learning curve for any of us on the inspection side of the elevator business.

I look at my own background and note that even after 43-plus years in the industry, there is still a great deal to learn and understand. I would hope all inspectors recognize the need for continuing their education, not just to get continuing-education units, but to gain a greater depth of understanding of the standards that help keep our industry safe and sustain the public trust.

Get more of Elevator World. Sign up for our free e-newsletter.