The Conflicting Roles of the Elevator Safety Code, LEED and ADA in Elevator Renovation

May 1, 2011

This article explores the issues related to the affects safety codes have on elevator renovations.

The lifespan of a cab interior is shorter than that of the rest of the elevator, and during its lifetime, an interior is likely to need multiple renovations. Choosing an interior is more than a matter of picking something out of a catalog or hiring a local cabinetmaker, however. It is a deliberate process of reconciling competing needs, including code requirements, intended use of the elevator, cost, downtime and aesthetics.

Learning Objectives

After reading this article, you should have learned about:

♦ The main provisions of the elevator safety code

♦ The role of an elevator in Leadership in Energy and Environmental Design® (LEED)

♦ Flammability of walls, ceilings and floors

♦ Americans with Disabilities Act (ADA) elevator requirements

♦ Balancing lighting concerns

The ASME A17.1 Safety Code for Elevators and Escalators is the elevator code adopted by most U.S. state and local governments, but it is not the only requirement that needs to be considered. The ADA sets guidelines and standards for handicapped accessibility. With the development of LEED standards, environmental concerns have been added to the mix of requirements.

The International Building Code defines the requirements of the various codes, but it doesn’t necessarily resolve conflicts between them. Marble walls added to make a building LEED compliant may add more weight to an elevator than allowed by the safety code. Thicker walls of a lighter material that meet the weight requirements may make the elevator too small to meet ADA requirements. When cost is the main concern, possible use as a freight elevator or fire-fighter elevator, building height, and Canadian and U.S. standards are added to the mix, it can become a web of confusion and conflicting demands.

Renovation also raises the overall stakes with regard to code compliance. Many older elevators that do not meet modern code met the existing standards when they were built and are thus allowed to operate under so-called “grandfather clauses.” Once a grandfathered elevator is renovated, however, it must be brought up to current standards, regardless of its history. The simplest way to avoid surprises (and requests for code variances that may be denied) is to work with a company with a product that meets the requirements of A17.1.

Walls and Ceilings

Of primary concern in any building is the possibility of fire. While many people think that material safety data sheets address fire concerns, they do not report the results of the required elevator code test. The flammability standards for testing of materials used on elevator walls, floors and ceilings are defined in A17.1-04, Section 2.14.2. Contractors doing elevator renovation must understand these requirements and use products that meet those requirements.

To be compliant, wall and ceiling materials must undergo the American Society of Testing Materials (ASTM) E84 test. Floors are subjected to the ASTM E648 test. In both of these, sample materials are burned to measure their characteristics. Materials considered nonflammable are generally exempt from testing. Glass, steel, aluminum, bronze, stone and drywall generally fall into this category. All other materials used on the walls, ceiling and floor must be tested in “as supplied condition.” A laminate wall, for example, must be tested both on the substrate and adhesive that will be used.

ASTM E84 is conducted in a 25-ft.-long burn chamber sometimes referred to as a Steiner Tunnel. Like any piece of scientific test equipment, the tunnel must be calibrated. A 24-ft.-long, 2-ft.-wide sample made from select-grade red oak planks is placed in the tunnel and set on fire to calibrate the system. When properly calibrated, the fire from the oak sample will spread from one end of the tunnel to the other in 5 min., 30 s. – plus or minus 15 s.

Materials to be tested are mounted face down on the top of the tunnel and exposed to a flame below. Windows are spaced along the tunnel so that the spread of the fire can be observed. Rate of flame spread, and smoke density are reported in terms of an arbitrary index. The flame spread index (FSI) and smoke density index (SDI) of the red oak sample are each given an index value of 100. A value of zero is assigned to the FSI and SDI of a mineral-fiber cement board tested under the calibrated conditions.

In the U.S., the standard for walls and ceilings is an FSI of 75 or less, and an SDI of 450 or less. These values correspond to Class B or Type II (described in National Fire Protection Association publication [NFPA] 101). The Canadian requirements are more stringent – an FSI of 25 or less, with smoke development of 450 or less. (NFPA Class A or Type I.) In areas enforcing the National Building Code of Canada and where elevators are used for fire-fighters, an FSI of 25 or less with smoke development of 100 or less is required. (There are exceptions to the required fire ratings based on building use, height or number of stories, and requirements of local jurisdictions.) Wall and ceiling flammability is covered by A17.1-04, Sections 2.14.2.1.1 through 2.14.2.1.3.

Floor Covering

Floor covering, underlayment and the corresponding adhesives or mortar are tested to a different standard and face more stringent requirements than floor coverings used elsewhere in the building. The carpeting that meets code in the hall in front of the elevator, for example, may not meet the elevator safety code and could be completely unacceptable if used inside the elevator. Grand fathering also plays a role, sometimes to the detriment of the renovation. In cases where the existing floor is serviceable, many elevator renovators attempt to save money by leaving the existing floor intact. If the floor has been grandfathered in, however, renovation renders it unacceptable. Unless there is documentation to show that the floor materials meet code, the floor will not pass elevator-code inspection. Elevator inspectors can (and have) insisted that undocumented floors be replaced, even if it means ripping out other compliant renovations. Renovation is covered by A17.1-04, Section 8.7.2.14.

In E648, a flooring test sample is mounted horizontally to the floor in an E648 test chamber and receives radiant energy from a gas/air-fueled radiant panel mounted above one end of the sample and inclined at 30°. This radiant panel generates a radiant flux along the length of the test sample. A gas-fired pilot burner is used to initiate the ignition in the test sample. The distance the flooring system burns to extinguishment is converted to W/cm2 and is reported as critical radiant flux (CRF). This is the minimum radiant energy a fire needs to sustain flame propagation in the flooring system. In this test, a higher number indicates a more flame-resistant system (i.e., 0.45 W/cm2 is better than 0.22 W/cm2). The more energy required to keep the floor burning, the more flame resistant it is; thus, the higher the CRF, the more flame resistant the flooring.

The elevator code requires flooring to have a CRF of 0.45 W/cm2 or higher and is sometimes referred to as Class 1. Typical flooring used throughout many buildings with a CRF of 0.22 W/cm2 is considered Class 2 and not suitable for use in elevator flooring. Floor-covering flammability is covered by A17.1-04, Section 2.14.2.1.5.

Ventilation

During renovation, ventilation issues are often overlooked, and sometimes a new interior covers existing vents. A17.1 requires elevators to have natural ventilation equal to 3.5% of the floor area (about 142 sq. in. in a typical 2500-lb.-capacity elevator), part of which can be accounted for by the gap in the door and ceiling-fan opening. Since code also requires the ventilation be equally divided be-tween floor and ceiling, toe vents are therefore more than decoration, and covering them up is a code violation.

The safety code also requires that openings up to 12 in. above the floor be small enough to prevent the passage of a 1-in.-diameter ball. Vents more than 72 in. above the floor must be small enough to prevent passage of a 2-in.-diameter ball. All vents must be guarded to prevent straight-through passage of any item. Ventilation is covered by A17.1-04, Section 2.14.2.3.1.

Ceiling Lights

A17.1 requires two or more lamps in an elevator. The minimum allowable illumination at the threshold with the door closed is 50 lux (Lx) or 5 foot candles (FC) for passenger elevators. (For freight elevators, the minimum allowable is 25 Lx or 2.5 FC.) Code also requires emergency lighting. When measured at 48 in. above the floor and approximately 12 in. in front of the car-operating device, the emergency lighting must be at least 2 Lx or 0.2 FC – roughly equal to the light provided by a lit match. The illumination can be measured by the use of a light meter. The emergency system must be capable of powering two lights for four hours.

Of the available lights, LED systems generate the least heat and are very energy efficient. Halogen lights, the least efficient, literally generate enough heat to fry an egg. LED lights use about 12% of the power used by halogens and cost about US$21 per year to operate, as opposed to US$183 for halogens. The extra US$162 that halogen costs is lost entirely to heat, and even a few halogen bulbs are enough to make a cab uncomfortably warm.

Some renovators recommend using motion sensors to further cut the cost of lighting. While this may make sense with halogen lights, motion-sensor systems can cost hundreds of dollars. If your renovation uses LED lighting (and most do), even a 50% reduction in electrical usage would save only US$10 per year. Payback would take decades. The most common systems currently used in renovation are six-bulb MR16 LEDs that use either 3, 4 or 5 W. All provide enough illumination, but quality of light varies depending on the circuit and type of diode. Most people prefer a “warm” light, perceived as slightly yellow, over a cool light, which is perceived as slightly blue. The warmth of light is measured in Kelvins (K), a measurement that is somewhat counterintuitive: Warm lights range from 2700K to 3500K. Cool lights range from 5000K to 7000K. You need to specify warm or cool light bulbs when you order your system.

Whether you choose LED or halogen, decide in advance if you want a dimmer or battery backup, because retrofitting after installation is expensive. If you opt for halogen, note that bulbs are required to have a safety coating that will contain shards if the glass front shatters. MR16 halogen bulbs with the proper safety coating are not generally available at home centers. Lighting is covered by A17.1-04, Section 2.14.7. Motion detectors are covered by Section 2.14.7.2.2.

Weight

Whatever renovations you make to an elevator, the change in weight cannot exceed 5% of the sum of elevator capacity plus its dead weight. (Dead weight is typically marked on the crossbeam.) Renovations in which you replace a plywood interior with glass or stone can easily exceed that and will affect the cab’s balance with the counterweight. If it does, the car may have problems leveling out when it reaches the desired floor, and there may also be a loss of traction. A change greater than 5% requires you to consult with an engineer and may involve re-balancing the system. It is much easier to solve any weight differentials at the design phase of a project. The cab-interior company should provide the total weight of the components to be installed when it quotes the job. Increase or decrease in the weight of a car is covered by A17.1-04, Section 8.7.2.15.2.

Walls and Ceilings Wall Panel Deflection

In some interiors, the cab walls contribute to the stiffness of the enclosure. Replacement panels must be stiff enough to provide the required support. A17.1 requires that force of 75 ft./lbs. applied horizontally to the wall meets the following standards:

- Deflection cannot exceed 1 in.

- Deflection cannot reduce the running clearance below the specifications.

- Deflection cannot permanently deform the walls. Strength and Deflection of enclosure walls is covered by A17.1-04, Section 2.14.1.3.

The Use of Glass

Glass used in elevator walls and ceilings must meet the following conditions:

- Tempered glass and laminated glass must conform to ANSI Z97.1 and subject to further treatments such as sandblasting, etching, heat treating, etc. that would change the original properties of the glass.

- All glass must be bonded to non-polymeric coating or film backing that will hold the glass fragments should the glass break.

- All glass must be mounted so that it will pass the standard drop test.

- Each piece of glass used in the interior must be marked with the standard to which it conforms.

Glass requirements are set by A17.1-04, Section 2.14.1.8.2. Ceiling-Hatch Requirements

In addition to proper lighting, cab canopies are required to have clear, unobstructed passage to a ceiling emergency exit. The exit must be at least 400 sq. in., with a minimum length of 16 in. per side. If the hatch swings downward, a minimum of 80 in. of clear headroom is required. Top emergency exits are covered in A17.1-04, Section 2.14.1.5.

ADA

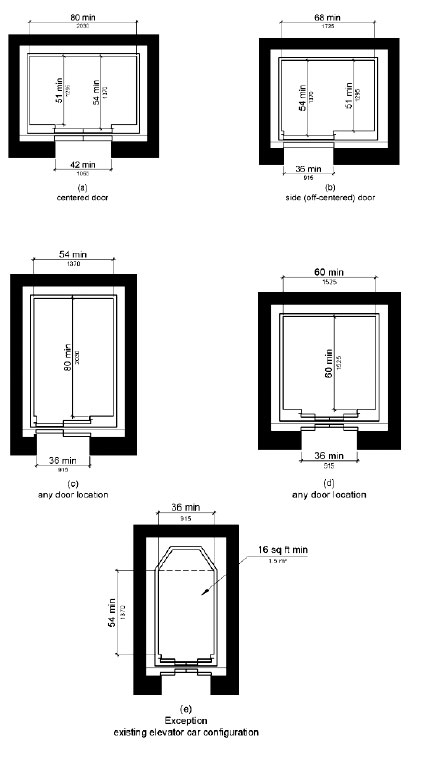

Unless a building is less than three stories tall or has fewer than 3,000 sq. ft. per story, new and renovated elevators must comply with the guidelines of the ADA. Three provisions have a particular affect on renovation plans:

- Elevator hall and car buttons must be mounted 42 in. above the floor. If not, the buttons will have to be relocated during renovation, and the size and location of the new panel must be taken into account when designing the interior.

- Handrails are not required by the A17.1 or ADA guidelines but are generally mounted 32-36 in. above the floor. There may be state or local requirement for handrail lo-cation, so you should check local interpretations.

- The cab must have enough room to accommodate a wheelchair making a 360° turn.

The last requirement requires careful planning. Exact specifications depend on the size of the cab and location of the door, among other things. (Figure 2) Unfortunately, in some older 2000- and 2500-lb. cabs, the width and length are small in relation to ADA standards. Installation of standard-thickness panels can be enough to make the cab too small and non compliant, requiring the use of thinner panels. In some cases, a cab is so small that installation of any wall panel whatsoever violates ADA requirements. Without proper variances, any newly installed panels would have to be removed.

LEED Certifications

LEED is a certification program that encourages design, construction and operation of environmentally friendly, “green” buildings. Beyond benefits to the environment, LEED certification can help the building owner by reducing operating costs and qualifying the building for special funding and tax credits. Because LEED certification generally results in lower utility costs and a healthier environment for workers, certification also enables landlords to charge higher rents. As a result, architects and building owners are placing greater emphasis on getting LEED certification.

LEED certification depends on the total number of points awarded for meeting standards in six categories: site sustainability, water efficiency, energy and atmosphere, materials and resources, and indoor environment. The current version of the LEED certification process excludes elevators from some (but not all) of those areas.

At the moment, the primary concern for elevator interiors is the use of formaldehyde in construction materials. While everything, including the human body, contains some formaldehyde, LEED standards specify materials have no added urea formaldehyde” (NAUF). NAUF standards apply across the board to everything from carpetying to insulation. They are of special concern in elevators when it comes to the adhesives used in the manufacture of plywood, as well as the adhesive used to affix laminates. Suitable substitutes are available and important to LEED certification but must be specified at the design-and-build stage. The certification process requires a paper trail, which traces NAUF compliance at every point in the supply chain – something that is difficult to recreate and obtain once the interior has been delivered to the job site.

In most states, NAUF is required only for LEED certification projects. The California Air Resource Board (CARB), however, has set what is called the CARB 2 standard, which, in effect, requires that California building materials meet the same standard that LEED sets. All substrate used in interiors installed in California must be NAUF or CARB 2 compliant, whether they are used in LEED construction or not.

Cost and Convenience

Cost is a concern in every renovation, and the choice of materials and contractor often depends largely on the budget. What budgets don’t consider is downtime during the renovation period; but downtime is crucial, especially in a one-elevator building. Owners must question if all users will be able to walk the stairs while the elevator is out of commission: Is there a doctor’s office on an upper floor? Are there apartments occupied by people with health problems? How will you meet their needs if the elevator is out of commission? The situation is not quite as severe in multielevator buildings. The absence of even a single elevator, however, can lead to crowding during peak hours (when people are arriving for work or headed home).

Unfortunately, elevator renovation has usually meant taking an elevator out of service for days while the work is done. Much of the delay is caused by the way wall panels are traditionally attached. Panels are hung on the wall with dozens of interlocking Z-clips. One clip is mounted on the elevator wall, and its mate is attached to the panel. Tolerances are tight, and there is very little room for error. If even one clip out of 20 holding a panel in place is misaligned, it is impossible to hang the panel, and it is virtually impossible to locate the culprit. It is a painfully slow process.

Newer systems, however, can reduce installation time to as little as four hours. These systems have panels that stack horizontally instead of hanging vertically. A typical system consists of a baseboard with four panels above it. (Sometimes proprietary) tongue-and-groove joints keep the spacing between panels even, align the panels in the same plane and keep them aligned. Any material used in vertical panels can also be used in a horizontal panel, including stainless steel, marble, glass, laminate and veneer. Because the panels are horizontal, brand-new designs are possible, but the interior can also mimic everything from traditional vertical panels to the classic New England-style frame-and-panel.

Stacked panels are often designed so that the elevator maintenance company can install them with no special training, thereby lowering installation costs. Because orientation of the panels removes the need for some of the intricacies required in vertical panels, manufacturing costs are also lower. This, combined with faster and less expensive installation, can result in significant savings over traditional systems.

Learning-Reinforcement Questions

Use the below learning-reinforcement questions to study for the Continuing Education Assessment Exam available online at www.elevatorbooks.com or on page 131 of this issue.

♦ What are the basic procedures required under A17.1-04 when testing for flammability?

♦ What are the primary ADA standards that affect renovation?

♦ What roles does LEED play in elevator design?

♦ What are the weight concerns during elevator renovation?

♦ What are the differences between vertical and horizontal panel installation?

Get more of Elevator World. Sign up for our free e-newsletter.