The Denver Museum of Nature & Science Denver, Colorado

Jan 1, 2017

KONE provides “a living exhibit” at busy museum under giant skeleton

submitted by Elise King, KONE, Inc.

The Denver Museum of Nature & Science is the fourth-largest natural history museum in the U.S. and is a cultural icon that welcomes visitors from all over the world. The museum is 116 years old, averages 1.6 million visitors a year and has 475 employees, 1,800 volunteers and 74,000 member households. It is open every day of the year, except December 25, and has events and activities going on at all hours of the day and night.

The museum’s four escalators are critical to guest flow and efficient facility operations, as they are in the heart of the museum and serve all three floors. The previous set of escalators were installed in 1985 and moved an estimated 50 million visitors in their 30 years of service. After mechanical problems with step chains that necessitated major repairs, the museum decided to hire a third-party consultant to evaluate the units’ condition and life expectancy. As suspected, the formal report recommended it was time to initiate plans for upgrade or replacement, and listed several options to proceed.

With information gathered from this report and feedback from the service provider’s site visits, the museum started to chart its path. Given that the escalators were vital to visitor circulation and that the museum would remain open during construction, there were several logistical and operational concerns, and many important factors went into the decision-making process. After a thorough request-for-proposal and interview process, the selection team unanimously chose KONE and its EcoMod solution to meet the unique challenges of the project.

Challenges

Both truss retention and replacement were considered for the project to provide the most efficient method of replacement and the best value for the museum. The original escalator installation was performed during the construction stage of the atrium building with a crane before the roof was installed. This approach was not an option for the replacement of the existing escalators.

The area around the escalators was also a very busy, open-style atrium with breezeway walks that connected several original buildings and additions. This open concept, while aesthetically pleasing, provided several challenges for escalator replacement, including a lack of attachment points for structural rigging to remove and install new trusses. Major modification to the structure of the breezeway walks would have been required to fit the larger replacement trusses.

Additionally, the units on the south end of the building were below a 58-ft. authentic fin whale skeleton, which would have required removal and reinstallation at considerable cost and risk to the owner. Safety was also a factor by the nature of the museum’s role as a regional learning center. A truss replacement would have required a significantly larger barricade footprint, which would have impeded the people flow of this major thoroughfare at the museum. This, in conjunction with patrons walking adjacent to a major construction project and its inherent safety risks, noise, dust and debris, led to the decision to use the truss retention solution, KONE EcoMod.

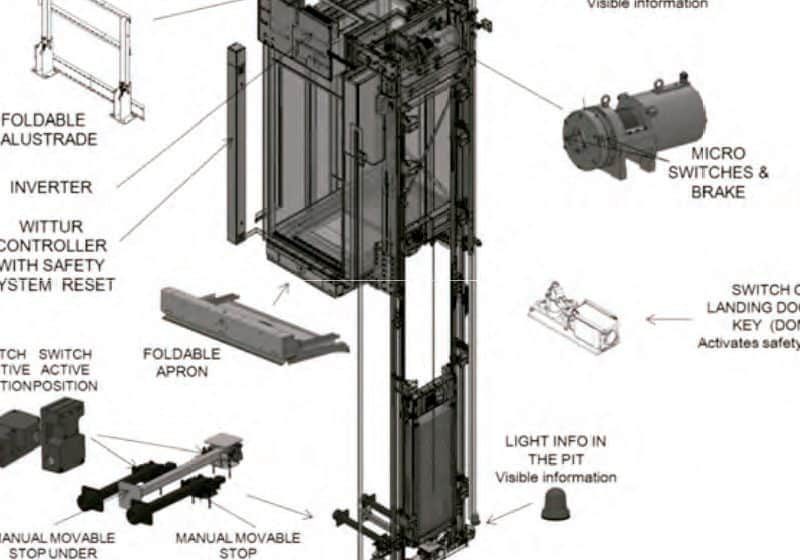

The EcoMod complete modernization solution provided the museum with new escalator technology, while retaining the truss of the escalators. This helped reduce costs and disruption to the flow of visitors.

Scheduling and Reception

Because programs and activities occurred in the museum around the clock, it was important to have some units in service at all times. As such, installation of the new escalators was scheduled in phases. The museum had record-breaking annual attendance while the first two units were being installed, a testament to how well the phased scheduling and truss retention approach worked. Both proved to be important factors that acted in the best interests of the museum.

Another surprising and unforeseen benefit for the museum was that the project became a popular “exhibit” among guests who were able to view the work and ask the crew questions. The museum received both verbal and written positive feedback from guests about the project. A visitor stated:

“When we were on our way through to the exhibits, we stopped to admire the work on the escalators. You can imagine how thrilled my kids were when the man working spoke with us and answered our question! He joked that he was a living exhibit. . . and so he was! At supper, my son announced that the best exhibit at the museum was the one on escalators. I’m sure it’s inconvenient for you to not have them, but we’re going to make a point of coming back several times during the process.”

Lastly, the ability to reverse direction of the EcoMod units was an important upgrade for the museum. Because of wear patterns on the old escalators, they could move in only one direction. Having the ability to reverse the direction with the KONE EcoMod units is an important feature for the museum, because it gives flexibility to switch directions depending on locations of events, programs and exhibitions that occur throughout the building.

Conclusion

The KONE team exceeded expectations during the entire lifecycle of the project, and EcoMod proved to be the perfect solution. The truss retention and phased scheduling approach worked as planned, and the entire project was executed safely and ahead of schedule.

CREDITS

- Building owner: City and County of Denver Building operator: The Denver Museum of Nature & Science

- Building services manager/project manager: James Calder

- Consultants: KONE Sales Representative Stuart Waida, Lerch Bates Inc., Project One Integrated Services and A Smart Elevator Solution

Get more of Elevator World. Sign up for our free e-newsletter.