The Development of an AMD for Elevators

May 1, 2013

by Liu Yingjie, Wu Xingjun, Wang Weixiong, Wang Xinhua, Lin Chuanglu and Song Yuechao

Elevator safety is drawing more and more attention from elevator technicians. Devices to monitor the state of an elevator not only help raise the safety level of elevators by detecting malfunctions beforehand, but also facilitate rescue work by sending immediate fault signals to rescue teams through general-packet radio service (GPRS). Most existing monitoring devices are passive monitoring apparatuses, which just use the information from the elevator’s main controller. This article introduces an active monitoring device, featuring the utilization of the current going to the frequency converter, which that current is indirectly measured by a non-contact sensor by analyzing changes in the rate of the current and comparing it with the recorded normal values. The monitoring device knows whether the elevator is running in a normal or malfunction state. This article addresses the configuration and working principles of the monitoring device and includes experimental results to validate its functions.

Background

Elevators provide great convenience with high speeds and large carrying capacities. However, due to their complexity in configuration, wear and tear of components, as well as harsh working environments, they may sometimes break down, even causing harm to users. The traditional method to keep an elevator in good condition is to provide regular inspections, in addition to proper maintenance. This not only requires a number of inspectors to carry out the task, it also fails to find some potential risks inspectors cannot foresee.

The number of elevators in China has increased quickly in recent years due to the country’s rapid economic development. This poses a great challenge for Special Equipment Inspection Institutes to ensure every elevator is in good condition. Researchers are seeking intelligent ways to deal with the problem. OEMs such as Otis, Mitsubishi and Hitachi have built their own monitoring devices for elevators that can monitor the operational state of the elevator and alarm in the event of malfunction.

The passive monitoring device has improved the safety of elevators, but its passive operation (i.e., its performance heavily depending on order signals from the controller of the working elevator) ensures the monitoring device will fail alongside the main controller when failure occurs within the latter. Some devices use the Internet to communicate between the elevator controller and monitoring device. The system then delivers causes regarding the failure to field technicians and rescue teams for troubleshooting and rescue work.

The Active Monitoring Device (AMD) presented here has built-in sensors and logic modules to analyze the state of the elevator in operation, independent of the lift controller. If the lift controller fails, the AMD can still send alarm signals to field technicians for emergency troubleshooting. These active-monitoring characteristics combined with online communication technology not only raise the safety level of elevators, but also enable earlier detection of potential failures that may lead to serious consequences, enabling preventive measures to be taken in advance.

Implementation System and Schematic

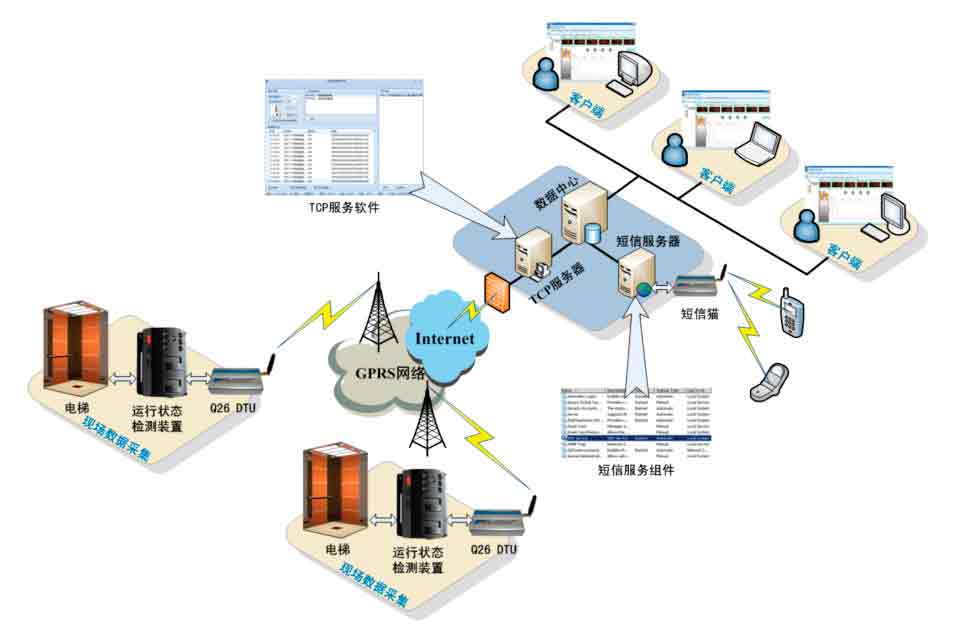

AMD Implementation System

The implementation system of the AMD is shown in Figure 1: the AMD diagnoses the real-time states of an elevator, such as normal operation, malfunction, inspection-operation or power-failure state. It then transmits the diagnosed analysis results through the Internet or GPRS to the remote-monitoring computer of the field engineers and technicians in charge of the elevator. The call-back technicians can then respond to the emergency or potential problems. The AMD provides an alternative for online passive monitoring method, therefore enhancing the safety level of the elevator.

AMD Schematic

The schematic of the AMD is shown in Figure 2. It is composed of a sensor unit to measure the input current and voltage of the frequency converter, a data processor for calculation of the collected current and voltage data, memory for storing collected data, and a signal transmitter for sending the processed results to the field engineers and technicians. The central controller is in charge of fault diagnosis and signal communication with the remote computer.

Hardware and Software Designs

The design of the AMD consists of both hardware and software designs. The hardware includes the power unit, central controller, data processor, sensor and data transmitter, all described as follows.

AMD Components

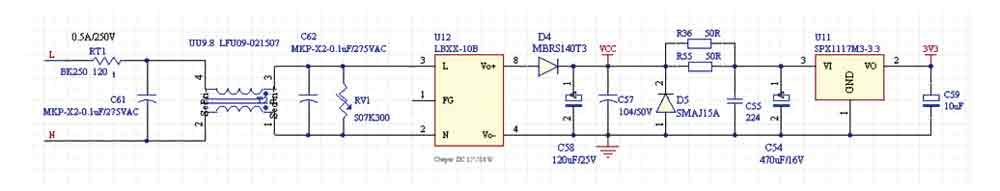

The power unit is designed for supplying 3.3 VDC to both central controller integrated control (IC) and data-acquisition IC (Figure 3).

The central controller IC for diagnosis of the elevator operational states is STM32 by ST INC. The pin connection of the IC unit can be seen in Figure 4.

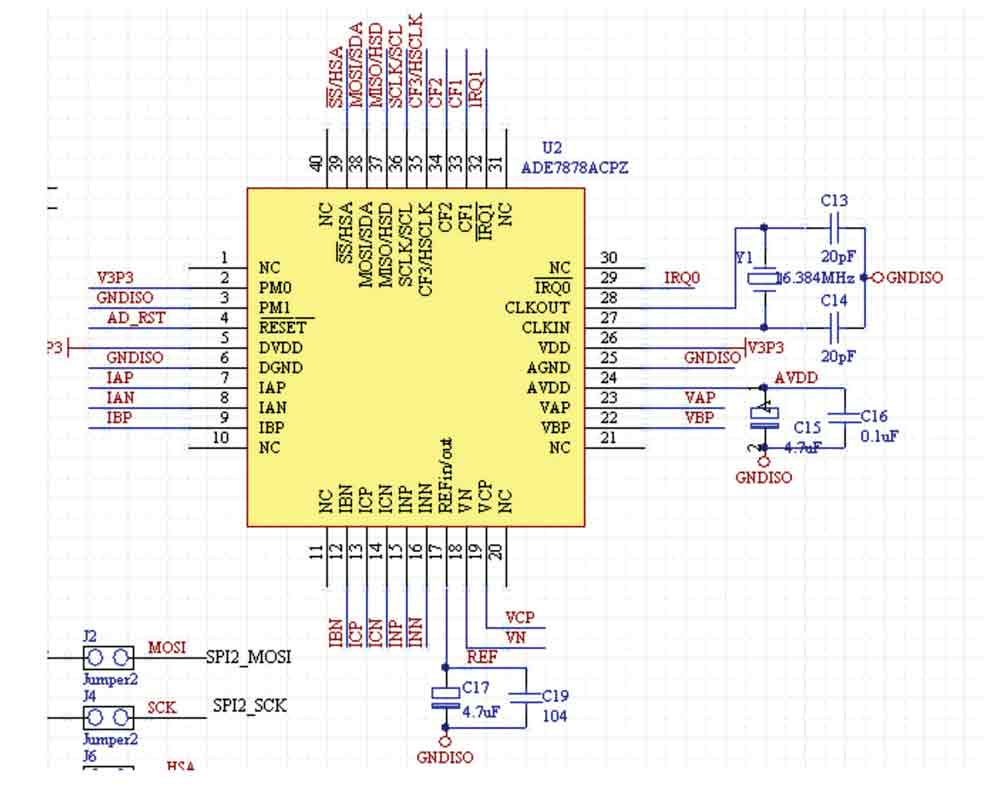

The data-processing unit is shown in Figure 5. Taking advantage of a specific current and voltage acquisition IC–Type ADE7878 for processing the measured data from the sensor unit, the root mean square of both current and voltage is made available by executing orders from the central controller IC via an I2C communication bus.

The analysis results are sent to the remote PC for call-back engineers and technicians by DTU in communication with the central controller via USART. The DTU signal-communication unit is shown in Figure 6.

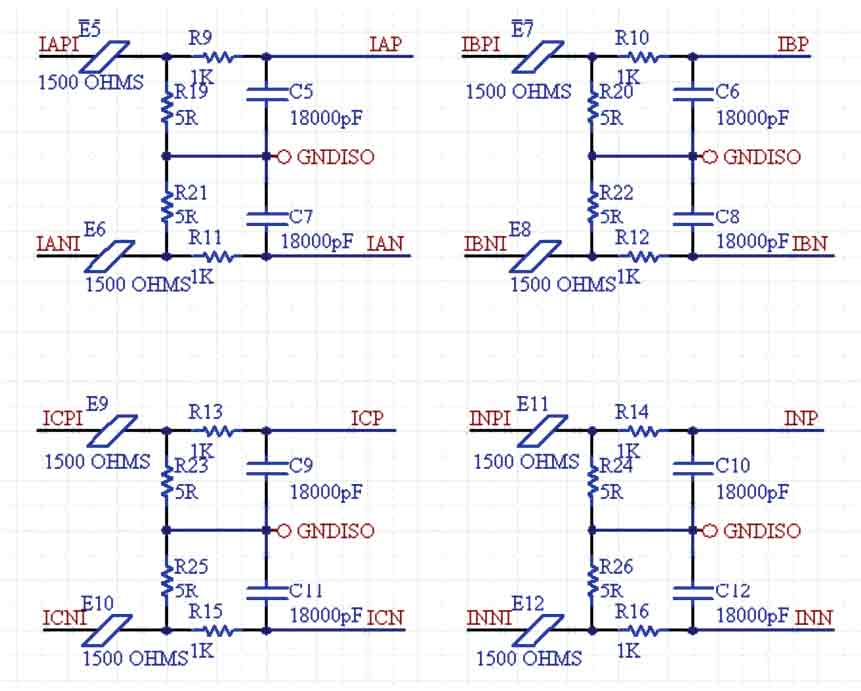

The sensors are used for measuring the input current and voltage of the frequency converter. The sensor unit is shown in Figure 7.

Fault-Diagnosis Strategy

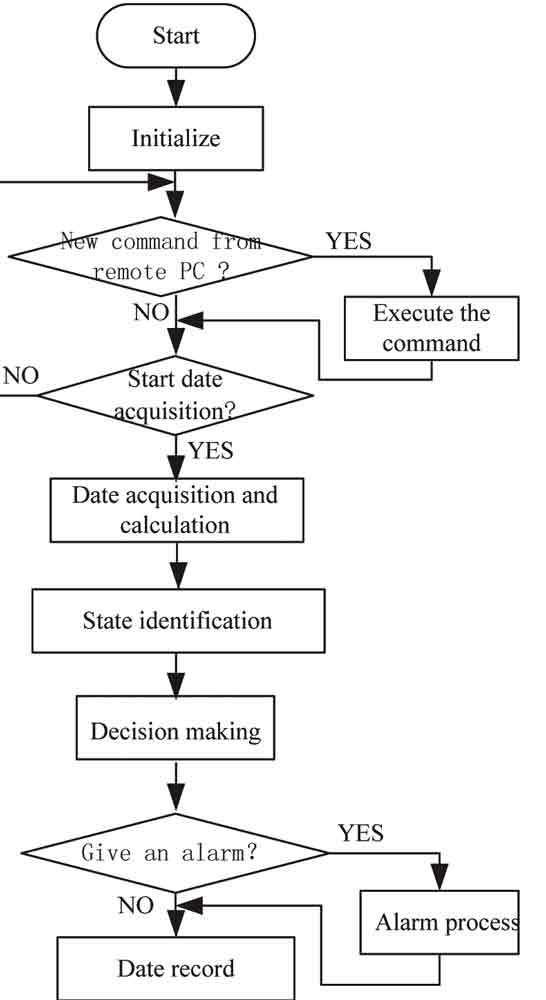

The AMD fault-diagnosis procedures are described in Figure 8. The AMD receives orders from the remote computer; if no new orders are given, the AMD executes routine online monitoring, measuring the real-time signals against the threshold values set to serve as criteria to trigger the abnormal-state identification. When the central controller IC executes the routine for abnormal-state identification, a sophisticated calculation strategy is applied, by which the currently acquired data is compared with the previously stored criterion data to determine the state of the lift. When the analysis is over, the central controller IC enters the decision-making phase by deciding whether to give out alarm signals based on the diagnosed state of the elevator.

User Interface

The AMD user interface is used for both online elevator-state monitoring and data analyzing. It contains the basic information of the elevator being monitored, such as type and specification, the failure records made by the system when the elevator is in the state of malfunction and the malfunction rates during a certain period of time, for statistics. The user interface is developed in the C programming language (Figure 9). It communicates with the AMD via GPRS and enables engineers and technicians to set some AMD parameters remotely.

Experiments and Data Analysis

Experiments

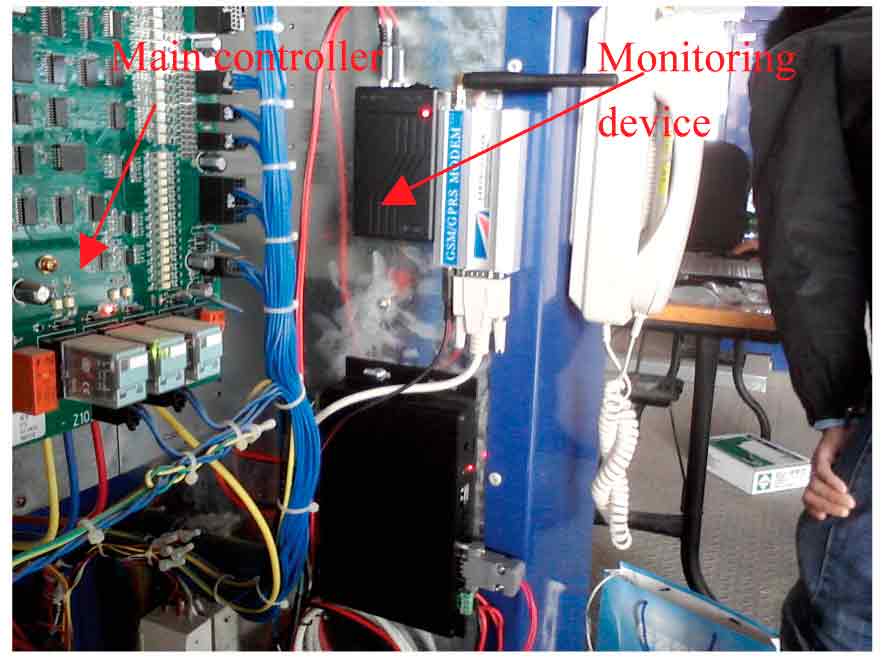

Experiments have to verify the performance of an AMD installed in an elevator (type Gmax 300) in a Guangzhou laboratory have been carried out. In Figure 10, the AMD is shown installed next to the main controller in the control cabinet of the elevator. To test its monitoring performance, an elevator malfunction is purposely triggered to see whether the AMD will detect it by analyzing the collected data on the current changes.

The experimental results show the AMD is able to distinguish the changes in emergency current and inspection current from normal operational current by means of its diagnosis-calculation strategy. Power failure can also be detected, and an alarm signal is triggered when an emergency event takes place. The monitoring-state transformation from normal to inspection shows the inspection state captured by the AMD, with the current for inspection mode smaller than that for normal-operation mode (Figure 11).

The state transformation from inspection to malfunction is shown in Figure 12. The malfunction state is detected by the monitoring device, the signal in the user’s interface is indicating the elevator is malfunctioning, and the alarm signal is going out to the field technicians on shift.

The typical changes in emergency and inspection current are obtained by the current sensor of the AMD (Figures 13 and 14, respectively).

Data Analysis

The statistical data from online monitoring can also be used for risk assessment. For example, the statistical data in Figure 15 regard the malfunction rates, which can be calculated and compared. These are available from different, specified periods of time, providing a data basis on which the risk assessment of an elevator can be made.

Conclusion

The AMD monitors the elevator state online and diagnoses malfunctions such as emergency stops, inspection state, and power failures. It is instrumental for field technicians to locate the cause of a failure in the elevator, while giving out immediate alarm signals to the rescue team in the event of someone getting entrapped. The AMD can also be used, to some extent, to avoid losses caused by lift malfunctions by constantly detecting the key parameters, which characterize malfunction probability. The distinguished advantage of the AMD lies in that it works in an active way – independent of or free from the lift control system. In the case of lift control failure, it keeps working properly. The experimental results have verified the projected characteristics of the device. However, much remains to be done to have it widely applied to elevators in use; in addition, reliability and large-scale application issues of the AMD need further research.

Acknowledgement

This R&D project is supported by the science and technology projects of General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China (2011QK321, 2012QK065, 2010QK080, 2012104016) and the projects of Guangdong Administration of Quality Supervision, Inspection and Quarantine (2011CT04, 2010CT04, 2010ZT02).

Figure 2: The schematic of the AMD

Figure 3: The AMD power unit

Figure 4: The AMD central controller unit

Figure 5: The data-processing unit

Figure 6: The DTU signal communication unit

Figure 7: The sensor unit

Figure 8: AMD fault-diagnosis procedures

Figure 9: The user interface of the AMD

Figure 10: The AMD installed in the control cabinet

Figure 11: The state transformation captured from normal to inspection

Figure 12: The state transformation, from inspection to malfunction

Figure 13: The current indication when the elevator is at emergency stop

Figure 14: The current indication when the elevator moves in inspection mode

Get more of Elevator World. Sign up for our free e-newsletter.