The Escalators with the Buffer Material as the Step Tip Part

May 1, 2018

Evaluation of an escalator model that adopts a buffer material at the front edges of its steps to enhance safety

by T. Kikuchi, H. Takahashi, A. Yamamoto, S. Yokoe and S. Nakagaki

This paper was presented at  Madrid 2016, the International Congress on Vertical Transportation Technologies, and first published in IAEE book Elevator Technology 21, edited by A. Lustig. It is a reprint with permission from the International Association of Elevator Engineers

Madrid 2016, the International Congress on Vertical Transportation Technologies, and first published in IAEE book Elevator Technology 21, edited by A. Lustig. It is a reprint with permission from the International Association of Elevator Engineers  (website: www.elevcon.com).

(website: www.elevcon.com).

Escalators are important pieces of equipment that support the infrastructure of society. However, the number of accidents involving escalator passengers is not declining, and, in most cases, the causes are either tripping or falling. Manufacturers make every effort to strengthen safety design, but accidents have not been eliminated.

To mitigate injury in the event of accidents involving passengers falling, Toshiba Elevator and Building Systems Corp. (TELC) has developed an escalator model that adopts a buffer material at the front edges of the steps. TELC evaluated this measure using head-injury criteria (HIC) and verified that this safety measure is effective for mitigating injury. This article presents details of this escalator model.

In recent years, there has been interest in escalators, not only in terms of convenience as a mere vertical-transportation means, but also in terms of improvement of safety.

Introduction

Escalators are typically installed in large stores, such as department stores and supermarkets, as well as in train stations and airport terminals. Escalators serve as equipment that supports the infrastructure of everyday life in indoor and outdoor settings.

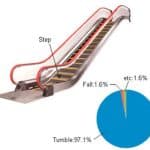

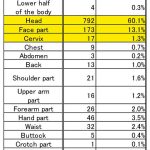

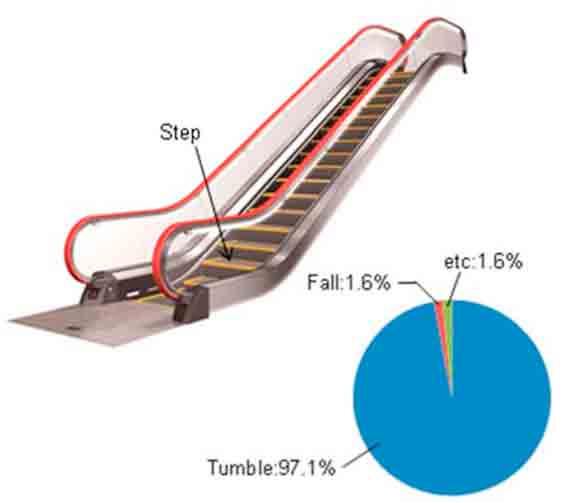

In recent years, there has been interest in escalators, not only in terms of convenience as a mere vertical-transportation means, but also in terms of improvement of safety. According to a study on escalator accidents by the Tokyo Fire Department, among those accidents where ambulances were requested, most involved a passenger fall or tumble (Figure 1). Moreover, regarding injuries, head injuries (including the face and cervix [neck]) accounted for the highest percentage, at about 75% (Table 1). Escalator manufacturers have focused on advanced technology and measures aimed at eliminating falls and tumbles. However, these efforts have not resulted in eradication of such accidents. We focused on mitigating critical injuries at the time of an accident and developed an escalator in which a buffer material is used at the front edges of the steps. The measures taken against such accidents are described here.

Overview of Buffer Steps

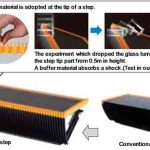

Conventionally, the steps used in escalators are formed by aluminum die-casting. The upper surface of each step typically has a yellow demarcation part made of plastic along three edges of the upper surface. Based on this conventional structure of steps, we added demarcation parts formed of a buffer material at the sharp angular part of the steps. By using this structure, in collisions with the sharp angular part of the step, where critical injuries are a major concern, the shock is eased, and injuries are reduced (Figure 2).

Moreover, by changing the yellow demarcations on the upper surface of each step from the three edges (as used conventionally) to four edges, the following advantages were obtained:

- The moving direction is easily recognizable, and passengers can easily get on the escalator.

- The level difference at the inclined part is recognizable.

- When getting on the escalator from the upper floor, the level difference of the steps is easily recognizable, mitigating the risk of uneasiness when getting on the escalator. Therefore, we decided to improve the safety of the steps.

However, we faced the following issues:

- The lack of a quantitative method of evaluating the injury-mitigation effect

- Selection of a suitable buffer material

Evaluation Method of Injury at Time of Fall

The first issue was to find a quantitative method of evaluating the injury-mitigation effect. There are various safety standards, such as for cars and playgrounds. We decided to evaluate the injury-mitigation effect quantitatively by defining an index based on the HIC value and probability of injury from an injury risk curve.

HIC Value

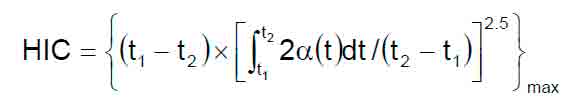

An HIC value is a value of the injury criteria computed from the collision acceleration of the head and is given by:

where t1 and t2 are arbitrary time points under acceleration response (t2 – t1 ≤ 36 ms), and α(t) is the collision acceleration.

The HIC value is used in automobile collision tests and in impact tests of impact-absorbing tiles (designed to mitigate injury when a child falls from playground equipment in a park, etc.). The test methods, test equipment, evaluation indexes, etc. are defined in detail by EN 1176 Part 1-11 + EN 1177 and EN 14808, and ASTM F1292 and ASTM F1487, etc.

Probability of Injury

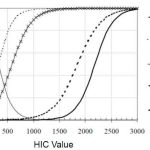

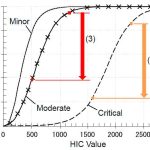

The probability of head damage, according to severity, can be estimated by applying the HIC value calculated from the collision acceleration to five kinds of injury risk curves shown in Figure 3. An injury risk curve is a curve that shows the relationship between injury probability and HIC value, and plots data showing the correlation between skull and cerebral damage based on physical examinations after actual accidents, etc. The injury probability is expressed with the vertical axis, and the HIC value is expressed with the horizontal axis.

The curves in Figure 3 are as follows:

- “No Injury”: probability of no injury

- “Minor”: externally caused head injury without a disturbance in consciousness, nose fracture, broken tooth or externally caused facial injury

- “Moderate”: fracture of a skull, or the fracture or the deep laceration of a face accompanied by loss of consciousness, etc.

- “Critical”: brain contusion, loss of consciousness or bleeding for 12 hr. or more, unclear hope of recovery accompanied by neuropathy

- “Fatal”: probability of death

As the HIC value increases, the more strongly the head collides with an object and the higher the probability of head damage.

Drop Test Equipment for Evaluation

Although evaluation indexes, test methods, etc. are defined in the standards for impact-absorbing tiles, such as those used in parks, or collisions of cars, there are no standards for accidents involving falls on escalators. Therefore, to evaluate the injury-mitigation effect of a fall while using an escalator, we developed drop-testing equipment for imitating head collisions at the time of a fall (Figure 4).

To imitate a head collision, we made a model of a human head with mass, rigidity and shape calculated from the average human head. This enables us to change the collision angle and falling height so that various types of falls by escalator passengers can be imitated. The test equipment turns the falling object toward the sharp angular part of the step and drops it automatically to reproduce a situation where the head collides with the sharp angular part of the step, and the collision acceleration at that time is measured. Next, an HIC value is computed from the collision acceleration, and the probability of head damage is checked by examining the injury risk curve. We estimated the injury-mitigation effect by comparing the injury occurrence probability with that of a conventional step.

Selection of Buffer Material

The second issue was selection of the buffer material. To define a withstand-load limit, we analyzed compression buckling in advance. Then, we selected candidate materials with closer Young’s modulus to the withstand-load limit we defined. We made demarcation parts using the candidate materials and selected materials with a high injury-mitigation effect.

Requirements for Selection of Buffer Material

The demarcation part installed at the sharp angular part of the step gets more shock absorbing. As it gets softer when a head collides, the injury-mitigation effect becomes large. However, if the demarcation part is modified to be nonrigid, there is concern about getting stuck by deformation of the demarcation part, a risk of the comb being broken and an increased risk of falling. Specifically, the following situations may occur:

- A child’s hand, leg, clothes, etc. might be caught.

- Breakage of the comb in the demarcation part by someone intentionally poking it (such as with an umbrella) or when a foreign object gets stuck in it

- The heel of a high-heeled shoe gets stuck at the demarcation part or higher risks for the passenger to fall when the buffer material gets buckled with the heel of a high-heeled shoe.

Thus, the injury-mitigation effect and a risk of deformation at the demarcation part have a relation of antinomy, and, therefore, we conducted various examinations.

Selection of Material

To select the material that does not increase the risk of deformation while having the injury-mitigation effect, we analyzed compression buckling in advance. We calculated the HIC value by analyzing the acceleration waveform at the time of a collision using a human-head model with an average mass and rigidity to collide to the demarcation part, approximated by a spring. The change of the HIC value when changing the Young’s modulus of the material used for the demarcation part is shown in Figure 5. However, if the Young’s modulus is too small, compression buckling may occur when stepping on the demarcation part with high-heeled shoes, etc. For this reason, a withstand-load limit (lower limit) used in analysis was defined, and the material selected as a candidate has a Young’s modulus close to this withstand-load limit. Next, the demarcation part was made using two or more selected materials. As risk of deformation is equivalent to that of a conventional step, a material with a high injury-mitigation effect was selected.

Injury-Mitigation Effect in Various Fall Situations

Analysis of Various Fall Situations

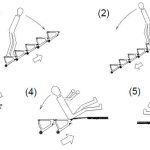

According to an investigation of escalator accidents, frequent falls involve “a fall to the upper floor at an inclined part,” which occurs in a sudden stop during upward movement, and the fall conditions at this time were determined as the evaluation index. A fall or tumble can mainly be classified into the following five categories, including the fall situation made into the evaluation index (Figure 6):

- A fall to the upper floor at an inclined part

- A fall to the lower floor at an inclined part (A head is bumped directly.)

- A fall to the lower floor at an inclined part (After attaching fall on its backside, the head is bumped directly.)

- A fall to the lower floor at an upper-floor getting-on-and-off part

- A fall to the upper floor at a lower-floor getting-on-and-off part

Injury-Mitigation Effect

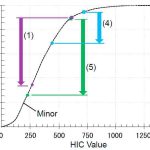

Regarding the injury-mitigation effect, we found that the probability of slight head damage decreased by about 50%, compared with a conventional step in case (1), which is the evaluation index. Moreover, the probability of injury decreased similarly in case (4) and case (5) (Figure 7). Even by using the injury risk curve showing slight head damage, the probability of injury gets higher, both for a buffer step and a conventional step. Because of severe fall conditions, they fall to the lower floor at an inclined part in case (2) and case (3). Therefore, we compared the probability of the medium degree or fatal head damage and found that probability of head damage was halved (Figure 8).

Discussion

We developed an escalator with installed demarcation parts formed of a buffer material at the sharp angular part of the steps. This buffer step, which can mitigate injuries caused by collision at the time of a fall or tumble, was accomplished without increasing the risks of getting stuck. Moreover, we confirmed that it was effective in mitigating injuries in an experiment that imitated various fall situations that occur while using an escalator.

Conclusion

Reduction of accidents involving escalator passengers has been an issue for many years in the escalator industry. The escalator industry had been concentrating on developing and producing the technology related to the elimination of the factors of fall (e.g., stopping escalators gently). Our products are developed by paying attention to mitigating injuries at the time of falls.

We will continue to develop a user-friendly product and supply it to the market and contribute to the realization of a safe and comfortable society.

- Figure 1: Classification of escalator accidents

- Figure 2: Configuration of escalator step with buffer material

- Figure 3: Probability of head injury classified by HIC value.

- Figure 4: Drop-testing tool for measuring HIC value

- Figure 5: Relationship between Young’s modulus and HIC value

- Figure 6: Various fall situations

- Figure 7: Relationship between probability of head injury and HIC value

- Figure 8: Relationship between probability of head injury and HIC value

- Table 1: Injury percentages by body part and number

References

[1] General corporation Japan Elevator Association. “The Measure Against Accident Prevention Concerning Escalator,” and elevator community, July 2006, p. 8-15.

[2] The accident prevention measure examination committee concerning escalator, “The Measure Against Accident Prevention Concerning Escalator,” 2005, p. 17.

[3] Masahiro Nakano, Hiroyuki Matsuura, Masaaki Tamagawa, Makoto Yamanaka and Toru Yukimasa. “The Rational Analysis of a Head Damage Standard Value (HIC),” and Biomedical Fuzzy Systems Association Vol. 2, No. 2, p. 57-63 (2010).

[4] The Ministry of Land, Infrastructure, Transport and Tourism. “The Safety Standard of Road Haulage Vehicles (Protection Technical Standard of a Details Notification Separate Attachment 99 Pedestrian Head).”

[5] Takahashi Hideo, Kikuchi Takayuki and Nakagaki Shigeo. “Kindmover Escalator With Safety Material Affixed to Step Edges,” Toshiba Review Vol. 69, No. 11 (2014), p. 50-53.

[6] Akihiro Yamamoto, Takayuki Kikuchi, Hideo Takahashi and Nakagaki Shigeo. “The Escalator Which Adopted the Buffer Material as the Step Tip Part,” the Japan Society of Mechanical Engineers Technology and Progress recent [such as an elevator and a play institution] technical lecture meeting lecture collected papers, No. 14-99.

Get more of Elevator World. Sign up for our free e-newsletter.