“The Future Ready to Hand”

Jul 1, 2024

41st Heilbronn Elevator Days

At the beginning of March 2024, elevator professionals came together again in Heilbronn, Germany, for two days. The 41st Heilbronn Elevator Days, under the motto “The future ready to hand,” once again reached more than 300 participants after the coronavirus break, thus making the conference one of the largest elevator conferences in Germany. The participants came from all sectors of the elevator industry, with traditionally particularly strong participation in Heilbronn from inspection companies such as TÜV and Dekra. More than usual at elevator conferences, large operators such as the railroads, airports, cities, authorities and industrial companies were also represented. This guaranteed a wide range of perspectives, especially during the breaks and at the wine tasting in the evening.

The accompanying exhibition also continued to grow, this year for the first time into a container on the forecourt of the Harmonie event building. There, Hydroware from Ratingen near Düsseldorf, Germany, presented its hydraulic and cable elevator systems. The company has already successfully placed the mobile showroom in German-speaking countries 30 times. CEO Volker Hager said that he wanted to become better known in the market in this way and “win new customers with new products.” More than 30 exhibitors were present, most of whom presented elevator components from Germany.

As always, Prof. Georg Clauß from organizer Technische Akademie Heilbronn (Technical Academy Heilbronn), an institute for further education at Heilbronn University, welcomed the participants. Afterwards, the participants silently paid tribute to the late Gerhard Thumm from TK Elevator (TKE), who had been an active member of the conference’s board of trustees for many years and was also a frequent speaker.

The introduction was given by Klaus Dietel from TÜV NORD Systems, who, once again, compiled the program and also moderated the conference. He named rules and regulations, AI, recruitment of skilled workers, occupational health and safety and current products, as well as the “No. 1 vexing [issue]: cybersecurity” as important facets this year.

Summaries of all presentations given at the conference follow in chronological order:

European Directives and standards, Eberhard Vogler, TKE Innovation and Operations: The harmonization of five standards of the EN 81 family based on the old mandate M/549 EN was published in the Official Journal of the European Union on August 21, 2023. In contrast to part 70, parts 21, 28, 58 and 77 do not contain any technical changes. The former versions are still applicable until February 21, 2025. The declarations of conformity must be updated by the same date. Harmonization was rejected for Part 71 Vandalism.

Harmonization in the EN 81 family based on the new mandate M/599 was ratified on October 5, 2023, and affects all other EN 81 standards, including Parts 20 and 50. Publication dates will be between 2025 and 2030. Building requirements are national law, and therefore not included in harmonized standards. Content relevant to elevators will probably be moved to informative annexes. In the transition phase, it is therefore best to specify these in the contract with the customer.

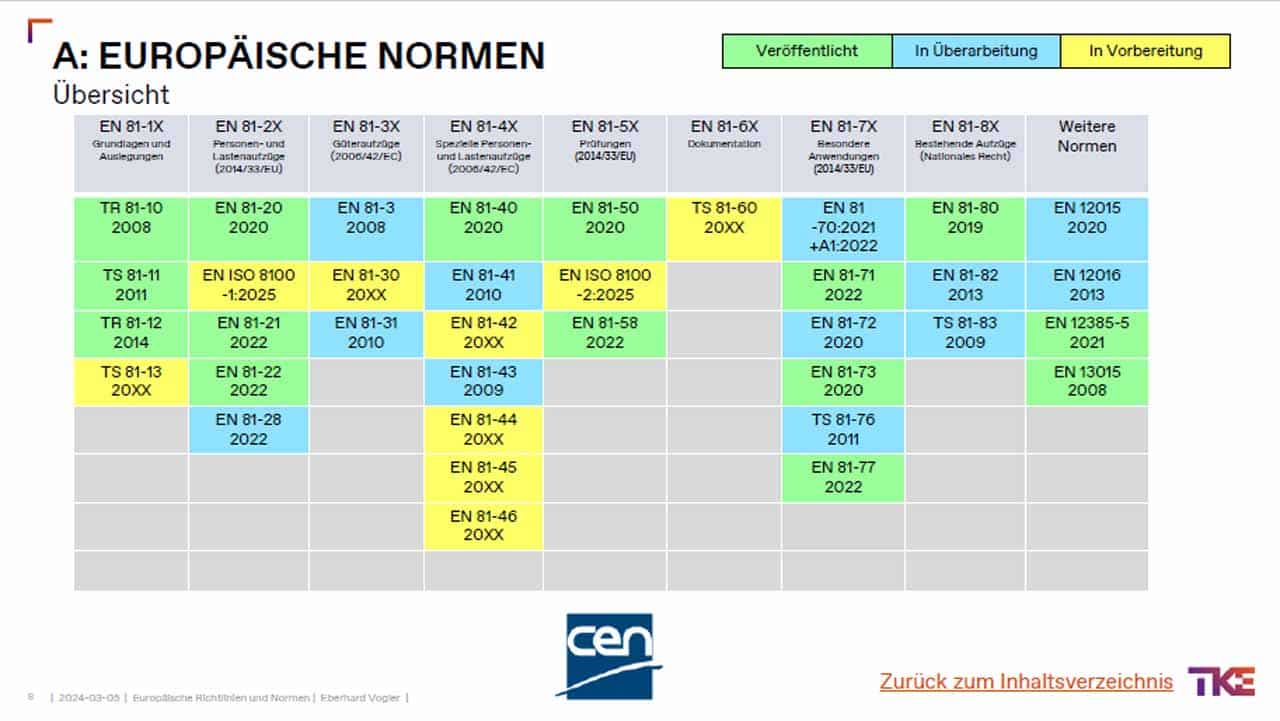

Following this, Vogler went through the list of European standards in detail and commented on the parts regarding changes that have been made (Image 1).

The European Union (EU) Machinery Regulation (MR) 2023/1230 was published on June 14, 2023, and is therefore still quite new (German text. It is also available in other official European languages). Interpretations, adaptations of the standards until Q3 2028 and initial implementations are underway. It replaces the Machinery Directive (MD) 2006/42/EC and affects elevators complying with MD of the EN 81-3x and EN 81-4x families, as well as escalators and moving walks. New features include a digital declaration of conformity and a digital operating manual (comparison old/new in English language only). It came into force on July 19, 2023. The old MD must be applied until January 19, 2027. Then, the new MD must be applied from January 20, 2027, without a transition period (Attention: Dates have been belatedly changed!).

A survey on the revision of the Lift Directive (LD) into a Lift Regulation (LR) is currently underway.

The next point of Vogler’s presentation was a detailed discussion of prEN 81-76 Safety rules for passenger lifts for the evacuation of persons with disabilities (short title). The new version is expected in summer 2024.

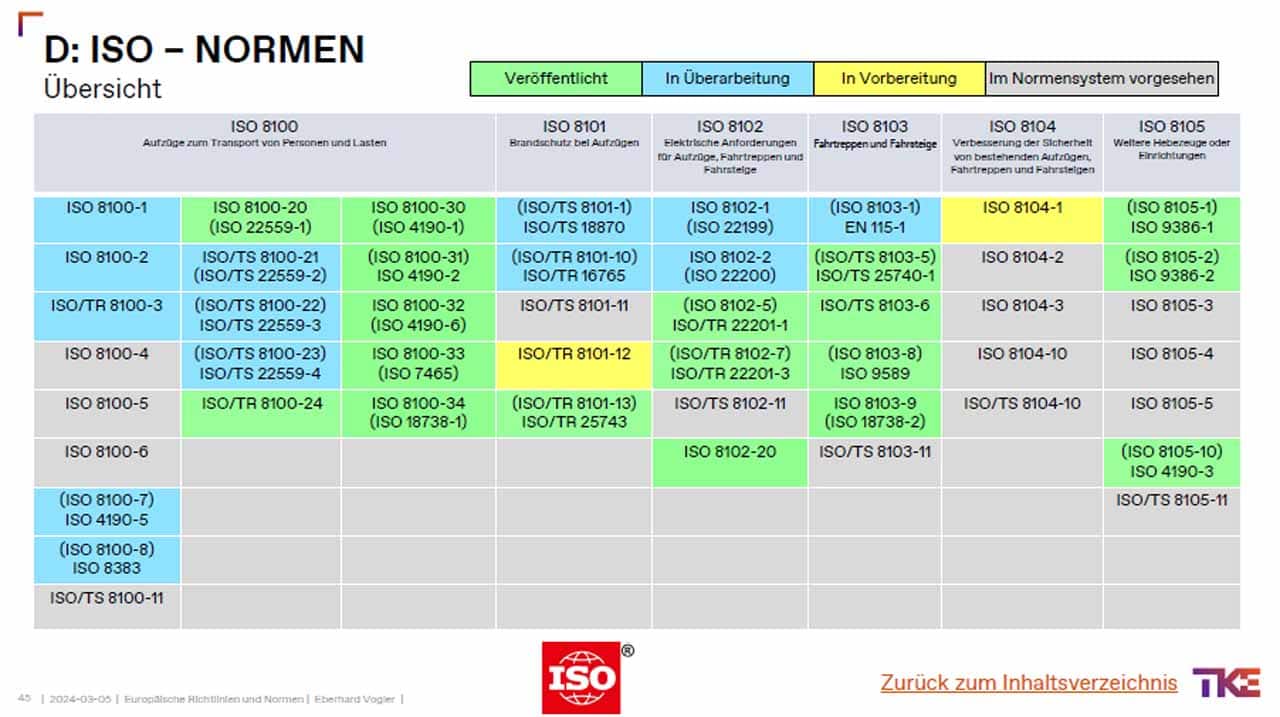

The presentation concluded with an overview of the ISO 81xx family as the stepwise successor to the EN 81 family. Due to time constraints, Vogler only showed the list of parts (Image 2).

The new regulation on the ÜAnlG + Guide for elevator panels, Axel Stohlmann, TÜV NORD Systems: There exist only two working drafts of the Act on Systems Requiring Inspection (Gesetz über überwachungsbedürftige Anlagen ÜAnlG); a draft bill should be available at the end of Q1 2024. Therefore, Stohlmann only provided information on the further development of the law for systems requiring inspection, upcoming innovations and changes, as well as the future of the Ordinance on Industrial Safety and Health (Betriebssicherheitsverordnung BetrSichV). The Product Safety Act and the ÜAnlG still apply in conjunction with the BetrSichV. Stohlmann does not expect a paradigm shift for systems requiring inspection and work equipment.

He also presented and explained a helpful hierarchical overview of selected regulatory bodies in Europe on the nature of elevators, placing them on the market and conformity assessment procedures:

- Technical Committee Lifts, Escalators and Moving Walks (CEN/TC 10)

- National Mirror Committee in DIN (NA 060-33-01 AA)

- Experience Exchange Group of Notified Bodies (NB-L)

- Experience Exchange Group of Notified Bodies (ZEK and EK 3) and in Germany on the operation and testing of elevator systems

- Federal Ministry of Labor and Social Affairs (“Bundesministerium für Arbeit und Soziales,” BMAS)

- Committee for Operational Safety (“Ausschuss für Betriebssicherheit,” ABS)

- Federal Institute for Occupational Safety and Health (“Bundesanstalt für Arbeitsschutz und Arbeitsmedizin,” BAuA)

- Federal States Committee for Occupational Health and Safety and Safety Technology (“Länderausschuss für Arbeitsschutz und Sicherheitstechnik,” LASI)

- Experience Exchange Group of the Approved Inspection Bodies (“Erfahrungsaustauschkreis der zugelassenen Überwachungsstellen,” EK ZÜS and AK 2).

The operator has the say — availability — costs — panels, Peter Berresheim, Hundt Consult: The operator’s interest is to make its elevator available for use in a safe and legally compliant manner with the highest possible availability and at the lowest possible cost. Due to the wide range of requirements, making the right decisions is becoming increasingly challenging. In terms of safety, operators must be familiar with the law and standards. They must bring together all those affected and/or use suitable service providers. Nevertheless, misunderstandings and misjudgments occur time after time, which can only be overcome with even greater organizational effort to protect one’s own interests.

The forthcoming EN ISO 8100-1/-2 — outlook from the manufacturer’s perspective, René Hermann, Schindler Aufzüge (Elevators) on behalf of the Swiss Lift Association (“Verband schweizerischer Aufzugsunternehmen,” VSA):

Work on developing a global ISO standard based on EN 81-20/-50 began in 2014 with the decision at the plenary meeting of CEN/TC 10 in Helsinki, Finland. The first roadmap projected the end of 2022 as the date for publication of the standard, which we now know will probably be at least Q1 2025. The industry needs planning reliability. Therefore, Hermann questioned the way in which these ISO standards are created to maintain an appropriate balance between effort/costs, results/scope and time/deadline.

The structure and content had — and still must be aligned with —CEN/ISO rules, i.e., building requirements, which are not included in the normative part. There were also many new technical requirements, such as new suspension means and vertical sliding doors, as well as automatic rescue systems and SIL-rated safety circuits instead of PESSRAL. Hermann gave details of the content, as they are currently being discussed on the panels. The HAS consultant and the mirror committees provided thousands of comments on the initial papers, which have now begun to be incorporated.

The upcoming EN ISO 8100-1/-2 from the perspective of the testing organizations, Stephan Störmer, TÜV Austria Services:

Now that the formalities and technical additions in the revision of the standard have been completed, the testing organizations must make the standard testable and create reliable evidence. It has already been noticed that some tests on the system in compliance with EN ISO 8100-1/-2:2025 are either not non-destructive or not makeable at all, which has not yet been taken into account in the standard. Reliable evidence may only be prescribed by laws or ordinances, for example, but not in the standard itself. This shifts the decision to accept or not accept evidence, including all legal and economic consequences, largely to the testing organizations.

For a transitional phase, this problem will have to be solved individually with the understanding and goodwill of all those involved. Störmer described specific examples of a procedure for SIL-rated circuits, suspension means, doors pendulum impact tests and opening force, access to the shaft pit, as well as the strength of shaft walls. He hopes that the MR will reduce this problem, at least for conformity assessment in accordance with 2014/33/EU.

Requirements for elevators today – digitalization and sustainability using the example of the EOX elevator system, Matthias Bartsch, Daniel Stephan, Thyssen Aufzüge (Elevators):

The lecture began with a presentation by TKE, including its sustainability goals. EOX has already been reported on in detail in ELEVATOR WORLD Europe (November-December 2022), so here are just a few key words about the product: machine-room-less, belt drive, 450 to 1000 kg, 1.0 m/s, up to 15 stops, regenerative drive with standby and eco mode, 100% LED lighting in cabin and shaft, Internet of Things (IoT)-capable and AI-capable hardware, intelligent sensors, e.g., optical sensor in cabin and shaft; 7-in. TFT multimedia display with infotainment in the cabin, elevator call via cell phone app, online customer portal with daily energy report, wireless software update for digital services, cloud-based intelligent service, production in Europe with 100% green electricity, European Environmental Product Declaration (EPD).

How do we attract skilled workers? Addressing applicants in an attractive way, Nicolas Sacherer, Permoser + Partner:

The number of applications and the quality of applicants are declining. At the same time, applicants’ expectations are rising. By 2025, there will be a shortage of nearly 400,000 skilled workers across all sectors in Germany. Efforts will increase sevenfold to close the gaps in a company. Therefore, there is an “employee market.” For companies, this means taking the same approach to customer acquisition by persuading and negotiating. Managers must also become active internally and prioritize the issue accordingly.

Sacherer gave three tips for finding employees more quickly:

- Get away from comparability, i.e., away from text-based and interchangeable job advertisements toward exciting, thoroughly personal insights into the job, workday and working environment. Such videos do not have to be of Hollywood quality. Costs: mid four-digit amount.

- Address stable candidates who are willing to change jobs and who cannot be found on job exchanges. Instead, use cell phones and social media such as Facebook, Instagram and LinkedIn. Use paid advertisements to gain followers instead of being active yourself. Costs: €30 (US$32.45) to reach 10,000 people in the region per day.

- Get away from cumbersome application processes. Only ask for essential criteria at the beginning, e.g., vocational training. Duration for candidates: maximum 2 min, i.e., no cover letter and/or CV. Then call within 24 h including asking for documents.

Although the quality of applications via headhunters and recruitment agencies is (still) better, the number, costs, level of awareness and overall better results speak in favor of social media recruiting, even ahead of job exchanges, newspapers and employment agencies.

Sacherer listed what you need for such campaigns at the end of his presentation: Attractive photos/videos, edited pictures, a promotional text, a landing page with quiz, a Facebook business manager and credit card and a telephone guide.

AI — basics — potentials — risks, Prof. Alexander Jesser, Heilbronn University of Applied Sciences, Embedded Systems and Communications Engineering: Jesser sees Information Technology (IT) in a state of upheaval. He described data as “the oil of tomorrow.” He began with definitions:

- Digitalization creates the data foundation for digital transformation, i.e., new business models.

- AI includes machine learning (ML) or intelligent software and its networking. He cited Amazon and Zalando as examples from the retail sector, SoundCloud and Spotify for music, Airbnb for hotels, Uber and car2go for mobility and Jawbone, Runtastic and Myfitnesspal for sport/health.

According to Google search terms, interest in ML, AI and big data has been growing significantly over a long period. The cloud was one of the triggers. Since November 2022, ChatGPT has dominated interest by a wide margin. Surprisingly, most requests come from the Philippines, Peru, Algeria, Japan and Nepal.

AI is nothing new. The term “AI” appeared around 1950, ML around 1980, deep learning based on neural networks and more computing power around 2010. AI is just a different methodology for algorithms and processes. A limit to AI is not yet visible or definable.

Jesser gave the following examples: finding faces, recognizing faces (68 face landmarks), coding faces (126 measurements), and training faces, e.g., emotions, female/male. The recognition rate is currently 90% at high speed. The examples of confusion risks such as confusing a Chihuahua dog with chocolate chip muffin were quite amusing.

Ethical questions need to be clarified. His example of autonomous driving: How does AI decide when reacting when it has to choose between injuring people on the crosswalk versus swerving into an obstacle and injuring passengers? Who is liable for the decision? As further examples, he mentioned so-called deepfakes, e.g., when the face of an actress appears in a porn movie, or DeepNude, when women are undressed without consent.

When will robots be more intelligent than humans? In 2024, the intelligence of bees and mice will already be surpassed; we are working on the cat. Human intelligence is envisaged for 2029, at least in some areas.

Neural networks are based on brain structures. Input values are weighted and added up and subjected to multiple yes/no decisions. Multiple superimpositions result in neural networks. During training, the weighting can be changed iteratively to achieve the best possible approximation. Training is a large computational effort that takes time and for which many different input data must be available. There is no 100%, but a very high probability that the result is correct. Jesser described ongoing projects such as switching on street lighting for moving cars, predictive maintenance, lung scans for detecting COVID-19 infections and vehicle electrical systems.

Safety first? Occupational health and safety on elevators from the perspective of the various stakeholders, Udo Niggemeier, ASIB Niggemeier: Employers are natural and legal persons and partnerships with legal status who employ people, such as elevator installers, but also many operators if they use elevators commercially for employees, such as cleaners. Employers must identify and assess risks, define/implement measures, review them regularly and keep them up to date to prevent accidents. In doing so, he follows the triad in occupational safety: risk assessment, work instruction, tuition.

Risks for employees arise from differing areas, activities, qualifications and experience, among others. Actors such as elevator attendants, emergency rescue personnel, service personnel and even fitters are therefore at different levels of risk, which leads to correspondingly different measures.

There are one to two fatal accidents per year in Germany involving elevators. Niggemeier would therefore like to see a central accident register, consideration of occupational safety in standardization and interpretation of rules and regulations, setting an example and raising awareness of risks.

Preservation of a historic paternoster Kehrhahn system at Kampnagel, Patric Wagner, Imbora Aufzugdienst (elevator service), Jan L. Dumno, freelance elevator historian:

The first paternoster in continental Europe was built in 1884/85: The Dovenhof Building, on the corner of Branstwiete/Dovenfleet in Hamburg, Germany. After various detours and mergers, the Kehrhahn company developed into today’s TKE. Kehrhahn No. 70312, a demonstration paternoster with the special feature “Every cabin is different” was installed at Kampnagel (ironworks, large machines, cranes) in Hamburg. Key data of the installation: Commissioned on January 16, 1954, 12 cars for two persons, six portals (stops), 0.285 m/s, decommissioned in approximately 1981. An application for monument protection has been submitted.

The aim is to restore it to working order while retaining the original parts as much as possible. All cabins were in need of restoration partly because parts were missing, and they had to be lifted out of the shaft with a crane. The drive/technique was operational, but the drive shaft was cracked, making it necessary to rebuild and replace it. The electrical system was not suitable for approval and had to be completely renewed and modernized in the process.

Functional safety and cybersecurity — How does the automobile industry do it? Georg Schwab, AVL Software and Functions:

The increasing number of electrical (hardware) and electronic (software) functions in vehicles over the last 30 years has made it necessary to systematically develop safety mechanisms in compliance with recognized, manufacturer-independent standards. With the increasing networking of vehicles with their environment and over-the-air software updates, cybersecurity also had to be taken into account. Product safety protects people from technology, while cybersecurity protects technology from people.

Schwab presented the approaches and methods used in the automobile industry to inspire a transfer to elevators. The driver for cybersecurity is the responsibility for the joint avoidance of risks for users from the planner/developer to the manufacturer to the testing institute, i.e., over the entire life cycle of a system.

Cybersecurity on elevators – implementation of the TRBS 1115 Part 1, Katrin Schwickal, TÜV SÜD Industrie Service:

Risks must be regulated if the legislator deems a risk to be sufficiently high. Cyber attacks — including those on elevators — are an increasingly likely scenario and can lead to risks. Safety for users, therefore, means ensuring safety and security. Thus, there is a need for the new Technical Rule for Operational Safety (Technische Regel für Betriebssicherheit) TRBS 1115-1 Cybersecurity for safety-relevant measuring and control equipment to specify the BetrSichV based on European Directives.

Elevator components and their environment must be recorded, the effects assessed, cybersecurity (CS) measures defined, implemented and maintained. The process is considered horizontally and all components vertically to capture all risks.

In accordance with EK ZÜS resolution B 002, from April 1, the documentation submitted by the manufacturer or operator for handling cyber threats will be checked for plausibility by the ZÜSs. Schwickal also expects a more far-reaching obligation by including cybersecurity in ISO 81001:2024. Cybersecurity is already named as relevant in the draft: Lift components that can be connected to external systems must meet the requirements in ISO 8102 20:2022.

Get more of Elevator World. Sign up for our free e-newsletter.