The Impact of Pre-Stretching on Elevator Ropes

Jul 1, 2019

In this Readers Platform, the authors examine whether factory-stretched ropes deliver desired results.

Introduction

This article summarizes the main findings of scientific investigations carried out on different types of elevator ropes regarding their performance in the areas of stretch and elasticity considering pre- stretching and sheds a light on pre-stretching in comparison to the stiffness-optimized and low-stretch product options from the current Gustav Wolf product portfolio.

As your authors showed in Elasticity Behavior of Elevator Ropes (ELEVATOR WORLD, July 2015),[1] increasing building and traveling heights, high-usage levels, modern system designs, etc., are increasing the demands on the physical properties of suspension ropes in elevators. The trend toward saving costs and energy by reducing the size and weight of moving masses with regard to dynamic loads (e.g., drive and rotating parts) and static loads (e.g., the cab or car enclosure) further moves the operating point of modern suspension ropes into lower load ranges of the rope. An important consideration, in addition to the rope minimum breaking force and service life (or bending fatigue performance), is the stretch and elasticity behavior of a rope under load. Rope stretch and elasticity are directly related to the compressive deflection of the cab under load and thus have a significant impact on the behavior and performance of the elevator installation, as well as the subjective perception of the passenger on system comfort (e.g., car movement during loading and unloading, releveling of the cab and offsets of hoistway landings/cab sills).

Furthermore, many designers and users of elevator ropes are confronted with the choice between pre- stretched and non-pre-stretched elevator ropes, especially when it comes to ropes with a natural or synthetic fiber core. Some rope manufacturers recommend pre-stretched elevator ropes, and some do not. Others offer low-stretch elevator ropes. But, what exactly does pre-stretching mean, and what is the effect of it? Are there alternatives?

Methods of Pre-Stretching Ropes

According to Draka Elevator,[2] pre-stretching is defined as pre-loading ropes in a way that the main rope elements, such as core fibers, the core, wires and strands can settle/set under load prior to installation. The process step of pre-stretching can take place during or after the rope production process, whereas the effects of pre-stretching during rope production are negligible, as the factor of time involved is too short to get any benefits in terms of the setting process.

Improving elongation behavior by pre-stretching natural fiber core ropes requires a very high time factor; for this reason, some producers offer post- production, pre-stretched elevator ropes. But, even if ropes are pre-stretched after the production process, the effect can be assessed to be little to none. Though the speed is slower than during rope production, the time to achieve meaningful lower stretch is insufficient, because of a permanent setting of the rope. Natural fiber core ropes for elevators with effective long-time pre-stretching would be too costly. Under realistic conditions, ropes change reels a few times before they are installed on elevators. First, they move from production to master reels and usually from master reels to smaller warehouse reels for distribution. At the end, they are cut to length and wound from warehouse reels to small reels or coils, ready to be installed.

During such handling, strands and wires change position and tend to lose any benefit of a pre-stretching process. This is another reason why the effect of pre-stretching ropes is extremely small or absent.

Nowadays, experienced manufacturers of elevator ropes use suitable materials and production methods to minimize the permanent and elastic elongation of elevator ropes and to optimize the rope stiffness in the loading point. The results are elevator ropes with the property of “low-stretch,” which nominal data in terms of elongation show an improved performance compared to most ropes offered as “pre-stretched.” ISO 4344 indicates the maximum tensile force applied during both the pre-stretching process and the process steps.

The Effects of Pre-Stretching

The final rope modulus is not a quantitative value constantly available immediately after installation of the rope. Instead, the rope structure is subject to a settling behavior; after the settling has taken place, specific rope stiffness is constantly present in a certain load range. Figure 1 illustrates a rope elastic modulus between 2% and 10% of the minimum breaking strength as a function of the number of axial load cycles. All elastic moduli were related to the final adjusting value of the respective type of rope so that quantitative differences regarding the modulus of elasticity of the rope types evaluated at this point are deliberately not considered.

It can be seen that, qualitatively, the fact that a rope has undergone a pre-stretching process shows only a minor influence on its behavior in terms of reaching or achieving the saturation of its axial modulus of elasticity. Although the initial modulus in the first loading cycle does show an increase of approximately 18% due to pre-stretching, both curves approach each other very rapidly, depending on the number of loading cycles. Between several load cycles from z = 10 to z = 80, a difference in elastic modulus of approximately 2-2.5% can be assumed. From several cycles of z = 100 onward, no significant difference in elastic modulus could be detected.

Obviously, the rope’s inherent setting phenomenon, in which the components of the rope compress under load, has taken place, being shown in the dependence of the adjusting modulus of elasticity as a function of cycles of axial load. Furthermore, this has taken place despite any prior pre-stretching processes. However, this process can be seen as a short-term phenomenon that reaches saturation soon after installation. When looking at Figure 1, it is evident that no difference in the final modulus of elasticity could be achieved by means of pre-stretching, as both samples achieved the same value in their saturation phase.

The aforementioned laboratory test results could also be validated in true-scale elevator field tests. As shown before, it should be noted that for ropes with synthetic fiber cores (SFCs), the setting behavior can be more pronounced, so a longer setting period may be necessary.[1] Of course, the results shown in Figure 1 are dependent on the actual cyclic load applied in testing or in the actual application, and may vary quantitatively but not qualitatively.

Pre-stretching is sometimes deemed to reduce (but not eliminate) the amount of permanent elongation of newly installed elevator ropes, the aim being to eliminate the need for them to be shortened after installation. Figure 1 indicates that, as regards the amounts of permanent and elastic stretch, no significant difference is realized through pre-stretching, aside from the performance in terms of rope modulus.

Conclusion

As shown before,[1] suspension ropes with natural and synthetic fiber cores initially exhibit a significantly reduced rope stiffness and, therefore, modulus (about 50-60% of the final modulus) and approach their final stiffness slowly, compared to ropes equipped with mixed or full steel cores, which are naturally settled due to their construction. However, fiber core ropes may exhibit advantages when it comes to robustness of elongation and elasticity, considering rope twist and other installation- or application-specific aspects.[5] Parallel-laid elevator ropes with mixed or steel cores are especially delicate and tend to untwist easily during installation if not handled correctly. With this exception, parallel-laid ropes show a fairly good elongation behavior.

When considering the application of natural fiber core ropes, particular attention should be given to the actual performance of the rope in terms of elongation and modulus. This is highly dependent on the quality of the fiber core, and its components and manufacturing process.[2] The fiber core supports the strands when the rope is under load. A good natural fiber core stays firm and will not get compressed by the strand pressure, thus preventing excessive rope stretch. A good natural fiber core has a significant influence on reducing rope elongation and provides a stable modulus performance. For this reason, rope manufacturers with in-house core production can integrate and control the production within their own quality systems.

Often, the term “pre-stretched” is used for a rope that is actually showing significantly reduced and, therefore, low elongation and increased rope modulus performance. As shown in Figure 1, it can be stated that the effects achieved through pre-stretching are negligible under realistic conditions of use and do not replace the above-mentioned aspects with regard to a “low-stretch” fiber core. In fact, investigations have shown that “low-stretch” fiber cores from well-known manufacturers in all cases had a lower structural elongation than ropes with the “pre-stretched” predicate.

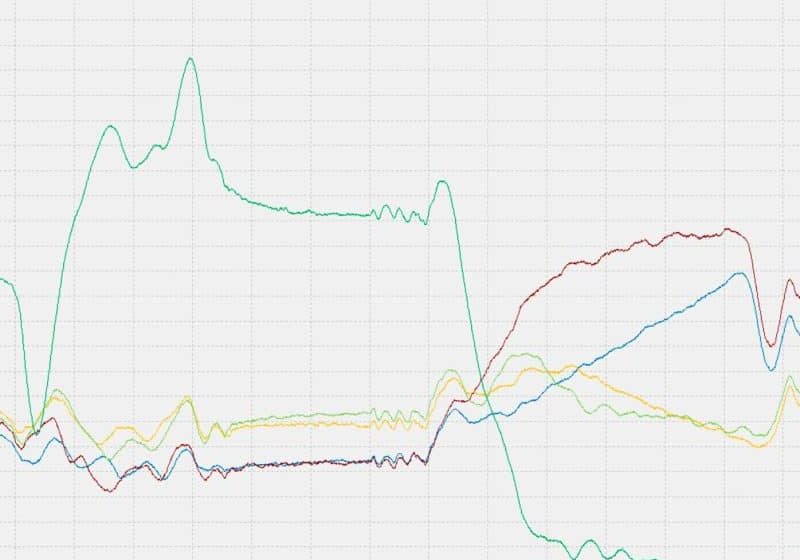

Ropes with natural fiber cores exhibit commonly a lower axial modulus of elasticity and stiffness than ropes with a mixed (fiber and steel) core or a full steel core.[1] However, for ropes with a fiber core, this characteristic may be increased. On the one hand, this can be reached by a flattening (compacting) of the outer wires/ strands, as carried out with the Gustav Wolf CompactTrac (ELEVATOR WORLD, March 2006)[3] or with a substitution of the natural fiber core by a high-modulus, high-strength synthetic fiber core as with Gustav Wolf ’s HyTrac (EW, July 2012).[4] Figure 2 summarizes the performance of Gustav Wolf ’s rope types in terms of the rope’s axial stiffness, minimum breaking force and bending fatigue lifetime to better provide for application-oriented use.

With the “Trac” series, Gustav Wolf has developed a new generation of elevator ropes. They should be considered for the ever-increasing demands on elevator systems and, in particular, for high-rise installations.

- Figure 1: Longitudinal modulus of elasticity in the work area of elevator ropes depending on the number of cyclic applications of axial load and rope permanent and elastic elongation

- Figure 2: Performance of Gustav Wolf ropes in terms of ropes’ axial stiffness, minimum breaking force and bending fatigue lifetime

References

[1] Franz, A., Stahr, K. “Elasticity Behavior of Elevator Ropes,” EW, July 2015, Vol. 60, Issue 7, p. 86-92.

[2] Draka Elevator. “Pre-Stretched and Low-Stretch Elevator Ropes,” Tech Tip 16, 2012.

[3] Wolf, E., Franz, A. “Rope Development for Elevators,” EW, March 2006, p. 122-126.

[4] Franz, A. “Development of Hybrid Rope for Elevators,” EW, July 2012, Vol. 60, Issue 7, p. 90.

[5] Gustav Wolf. The Rope Handbook, Revision 2, September 2017.

Get more of Elevator World. Sign up for our free e-newsletter.