The need for each country to have a directive for lifts and safety components is outlined.

There are many options and ways to meet Essential Health & Safety Regulations (EHSRs) for lifts. Some countries only use lift standards to meet EHSRs without a lift directive (LD); as a result, most modern technologies and innovations are unable to enter these markets. This causes limitations for manufacturing components such as guide rails, suspension means and machines. Notified Bodies (NBs) do not involve any evaluation according to an LD for the same reason. This can introduce limitations for design, manufacturing and inspection. Therefore, there is a need for having an LD in each country.

Introduction

With technological advancements growing rapidly, the need for keeping EHSRs growing as swiftly is very important. If regulations and standards are not agile enough, they will slow industry development. To achieve this agility, while ensuring passenger safety, the need for an LD rises. It enables countries to:

- Develop, design, manufacture and install any type of lifts covered by the LD

- Introduce innovations and technologies not yet included in lift-related standards

- Deviate from prescriptive harmonized standards to introduce more innovative and competitive solutions.

- Reduce the involvement of third-party certification bodies and reduce cost and concept-to-market time

- Develop a competent R&D and engineering organization, with necessary freedom and related responsibilities, to innovate and introduce safe solutions and products into markets.

Scope

LD Scope

LDs cover lifts permanently serving buildings and construction sites, installed in these situations:

- New buildings

- A building being used or already being used before the order for the lift was placed

- Existing hoistways in the replacement of existing lifts

- Lifting appliances with rated speed greater than 0.15 m/s

- Safety components for lifts

Lifting appliances with speeds less than or equal to 0.15 m/s fall under the Machinery Directive.

Lift Standard (EN 81-20: 2020) Scope

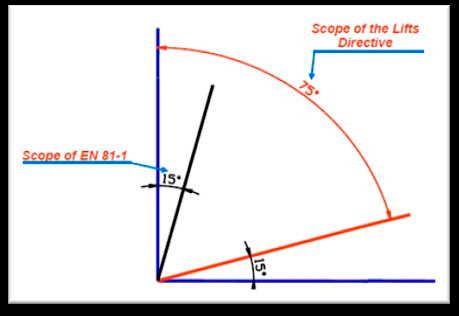

The scope for EN 81-20: 2020 is new passenger or goods/passenger lifts, with traction, positive or hydraulic drives, serving defined landing levels, having a car designed for the transportation of persons or persons and goods, suspended by ropes, chains or jacks, and moving between the guide rails inclined not more than 15° to the vertical.

Comparison

Compared with EN 81-20: 2020, the scope of an LD is very extensive.

Negative Effects of Standard Regulations and Obligations Without a Directive

Negative Effects on Development Advancements

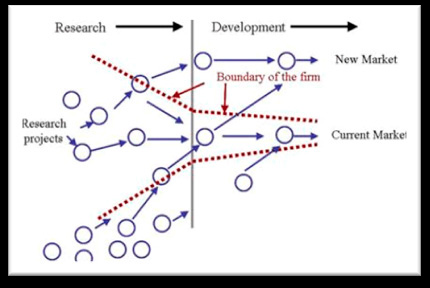

Considering the whole industry market without active organizations and companies, massive research and studies are required for industry developments. These studies are then bounded by firms and guidelines and proceed to development. Some studies are inevitably removed during this process.

It has been proved that numerous amounts of research and studies in all industries are necessary for a few, rare developments. If there is a boundary of firms, regulations and standards, all research conducted by stakeholders and knowledge enterprises in the elevator industry will plummet significantly. Therefore, there would never be an appropriate infrastructure for innovation in the industry.

Not Recognizing Similar Lift Equipment

Due to limitations in standards’ scopes and diversity of similar types of equipment, using the standards alone and as the only rule for everything will fail to cover the possible types of equipment that can be in an LD’s scope. Additionally, elevator systems have been installed in different periods for different uses, which has created too many regulations and standards for different elevator uses. An LD could cover all of that without limiting innovation and ideas. On a global scale, for countries in which standards and regulations are mandatory, the potential would be destroyed. By contrast, standards by the International Organization for Standardization are formed by including all members’ opinions.

Also due to limitations in standards’ scopes, there are usually too many editions of standards to cover all usages and aspects of the elevator industry, and these editions are rereviewed. Due to enormous numbers of standards with only a limited scope and the quick pace of technological advancements, it is safe to say that standards are usually far behind technology.

Why Are Standards Behind Technology?

Technology changes and advancements come quickly, and the elevator industry is no exception. These advancements can create new parts and components, breakthroughs and pieces of equipment that can lead to significant advantages, such as better energy efficiency, the use of fewer materials, more convenient construction, and systems with greater user-friendliness.

Examples can be found in the suspension system, such as the use of belts instead of steel ropes, a reduction in steel rope diameter or not regarding the rule, “No sheave diameter shall be less than 40 times the rope diameter.” Standards, such as the most recent edition of the European Norms standard, still prohibit such technologies. It is predicted that, in future reviews, these cases will be considered.

Why NBs Cannot Do Their Essential Jobs

One of the most important duties of an NB, in relation to standards, is risk assessment due to discrepancies in design, manufacturing and installation. These discrepancies should be evaluated according to directives. However, doing so without the directives (only using the standards) can result in many new designs and solutions with the same or even higher safety levels being rejected.

Conclusion

If each country required a general body of rules with a variety of uses, using strict standards alone would cause issues as described in this article. On the other hand, new technologies and advancements may not provide sufficient safety. That is why NBs are essential in the industry, and directives are meaningless without them.

Get more of Elevator World. Sign up for our free e-newsletter.