Our interview with Cenk Ceylan (CC), the CEO of ARKEL, a valuable brand that was born in Türkiye and managed to become a global brand quickly.

BY: I know it for certain, but for our readers who do not know, we would like to hear from you about the history of ARKEL, its formation and its journey to this day.

CC: ARKEL was established in 1998 as a two-partner company by Mr. Melih and Mr. Çağlar. Those from the industry know that the first designs started at Minimak with the motivation of Çağlar’s father who led the technical team of Minimak Asansörleri. When the products attracted the attention of the industry, they were advised to become an independent company, and the journey began. The company continued its journey with Mr. Melih and Mr. Çağlar until 2016. Being the first domestic inverter manufacturer in Türkiye and the commissioning of Adrive in 2003 were the first steps that directed the company into an entire control system, not just a control card. The exports and certification of products also started in that period. Therefore, starting exports very early allowed ARKEL to attract the attention of investors in the following years. In 2016, Mediterra Capital, a financial investor, purchased 70% of the company’s shares. In this partnership structure, we, as professional management, started to structure the management staff in 2017, some of whom were our colleagues trained internally at ARKEL, and some were professionals coming from outside the industry. This will be our eighth year as a staff. We continue on our way with the transfer of the company to another capitalist at the beginning of this year but with the same professional management.

BY: Who is Cenk Ceylan? Let’s get to know you a little bit.

CC: I was born in 1976 as the child of a civil servant family. Therefore, we traveled to several cities, so my education was a bit fragmented. I could not finish any part of my education from primary school to high school in a single location. I studied high school at Kars Anatolian High School and graduated from Istanbul Technical University, Faculty of Electrical and Electronics in 1998. I started my professional business life at Schneider Electric. At that time, I also completed my master’s degree at Kocaeli University. After my military service, I worked as an automation engineer at Çolakoğlu Metalürji’s OP2 power plant for more than three years. Subsequently, I was responsible for automation in the energy production department of Siemens for about five and a half years. Then, I worked as the Türkiye director of Rockwell Automation, a major American brand in the industry, for 11 years.

As it was the beginning of the Mediterra investment period, they were establishing a new structure, and we came together on an occasion. To tell the truth, what attracted me the most was that whenever I did interviews in the automation industry, they asked, “You have always worked in foreign companies; what do you think about this?” And I said, “I wish these technologies were produced in Türkiye so that we could serve a Turkish company. If I found such an opportunity, I would support it without a second thought.”

The person who inspired us caught me from this perspective. When I first heard that inverters were manufactured in Türkiye as well, I couldn’t believe it. I got very excited after looking into it, and I got even happier when I met Mr. Melih. His works, the story he created and the history and future of the company caused excitement. In this process that we have left behind seven years, to be honest, we have also had very difficult years. During these seven years, we experienced a pandemic, and there were economic difficulties in the country, but the industry is such an emotional and close industry that even amid difficulties, people can motivate each other and somehow keep each other afloat.

BY: You started your duty after the sale of ARKEL to Mediterra Capital. ARKEL was acquired by Swedish INNOVALIFT last year. When did this acquisition process start and how did it proceed?

CC: As you know, Mediterra is a private equity fund and operates as a financial investor. They have several investments in Türkiye and have now started the management of their third fund. ARKEL was one of the companies invested as part of the second fund, and ARKEL’s investment process started in 2016. In this regard, I would also like to thank Mediterra. As a very responsible fund, they are extremely sensitive about the future of the companies they invest in. Therefore, when choosing new investors to whom the companies will be transferred, they act by considering the compatibility with the company. This was a choice made considering ARKEL’s compatibility with INNOVALIFT, both structurally and strategically, and the potential benefits it would provide in the future. INNOVALIFT was also quite eager and exited about ARKEL. In this way, the transfer was completed.

BY: Who is INNOVALIFT? Could you briefly describe it?

CC: INNOVALIFT is an industrial umbrella company that can be considered as the infrastructure of LATOUR Group based in Sweden. LATOUR Holding has a structure that makes long-term investments in various industries. It has an industrial and services sections. The company also operates as a manufacturer or long-term investor in different areas. Their interest in the lift industry began approximately five to six years ago when they acquired a Swedish platform lift manufacturer. Following this acquisition, it created a multi-company structure by acquiring other companies suitable for the same business model and gathered its lift companies under the umbrella of INNOVALIFT. INNOVALIFT is quite a young organization and was established as an umbrella company in early 2024. Therefore, the acquisition process of ARKEL was carried out under the name INNOVALIFT.

BY: There are eight more lift companies from countries such as Italy and the U.K. under INNOVALIFT. These also include companies manufacturing communication systems as well as floor and car buttons. Is there any possibility of collaboration or branding in the future?

CC: INNOVALIFT emerged as a natural need as the business volume and the number of companies in its portfolio increased. It does not have a strategy to merge companies or create a new brand under its own name. The main purpose of this umbrella structure is to capture the synergy between companies operating in the same industry, doing different jobs and producing different products to ensure coordination between them and bring them together. These companies continue their operations as sister companies but fully independently, in line with their own business plans.

One of the questions people are curious about for the future may be whether the ARKEL brand will change under INNOVALIFT or whether INNOVALIFT will turn into a separate brand. However, the opposite is the case. INNOVALIFT acquires each company considering their own existing business plan and never directly requests any intervention or revision regarding these plans. Since LATOUR finds ARKEL’s five-year business plan appropriate, it prefers to continue independent management and even protect current management if possible.

In this process which we, as a Group, are new to, collaborations can only be considered to provide benefits without causing even minor losses or any distress to the current structures, systems and ecosystems of all of the companies. We think that ARKEL, in particular, can make great contributions to existing companies with its manufacturing and technological capabilities, and we see areas where we can support them accordingly.

BY: Does the founder Melih KÜÇÜKÇALIK have a partnership in the new structure? Will he continue at the company?

CC: Mr. Melih is a very valuable name not only for ARKEL but also for the industry. We believe that his contribution to the industry will continue and he will remain in the industry. After the acquisition made by INNOVALIFT, Mr. Melih no longer has a share in ARKEL. However, this does not mean that his relationship with ARKEL has ended. He will continue to work with us as a consultant in the areas of management, strategy and R&D. Moreover, this consultancy will not only cover ARKEL but also INNOVALIFT when needed.

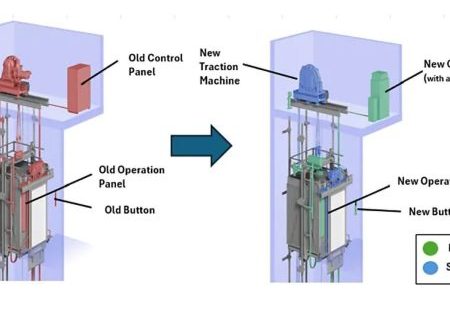

BY: ARKEL once started to manufacture gearless engines. Does the manufacturing continue or should we expect any development in this regard?

CC: We started to manufacture gearless engines around 2017, but we decided to end this in 2019. The most important reason for this was that engine manufacturing was not ARKEL’s area of expertise. As a company, we have never been an engine manufacturer. As for why we needed this product, we wanted to create a full-performance system by achieving harmony between the control systems and the engine. As a result of the trials we started in this line, we obtained quite successful results. The fact that parameters of ARKEL engines can be loaded automatically to our systems provided serious convenience in terms of both installation and commissioning. Engine quality was also quite high. We had no technical issues. However, when we looked at the manufacturing technology and structure of the engine, what we did was actually the assembly of the engine rather than engine manufacturing. From a commercial perspective, continuing engine manufacturing with this method was not meaningful for us.

BY: You have been very active in the Indian market for many years. Can you tell us about your investments there?

CC: We entered the Indian market through the channel of a dealer or distributor at the beginning. However, our activities started to become more comprehensive there after we established our own local structure in 2017. Since India is an emerging market for us, it had an important place in our strategic business plan during the Mediterra period. For this reason, we have reached a serious position in the market by strengthening our organization in India, attaching importance to localization and expanding our teams. Our ARCUBE product played a major role in the significant market share we gained in this process. We have gained a serious acceleration in the market with this product which is quite suitable for the Indian market.

At this point, we have seen that supplying the Indian market with manufacturing from Türkiye has become challenging in terms of costs and operations. We already knew that when we reached a certain scale, local production investment would be inevitable. Therefore, we decided to establish a manufacturing facility in India about a year and a half ago. Processes such as location selection and building construction took some time, but now our building is about to be completed and our machines have started to be shipped to the site. The machines will be commissioned gradually and we will start mass manufacturing as of July.

Our India operation, which has focused on sales and after-sales service until today, will be a copy of ARKEL’s entire structure created there. We have set up a manufacturing line with half the capacity of our facility in Türkiye at the first stage. India is a very important and high-potential market for us, but we have not invested in only India. The fundamental aim of this factory is to be close to the Asia-Pacific market and to strengthen our existence in the region.

BY: Can you position your market share in our country and around the world?

CC: In fact, I think it is not very healthy to make numerical statements about market shares in this industry. Because, unfortunately, associations in many countries are not even sufficiently aware of the number of lift installations, which is among the most basic data of the industry. It would not be right to give net market share figures in such ambiguous market values. However, we can talk more about the markets we have focused on and made intense efforts to date.

As ARKEL, we started our first export activities in the European market. Especially with the opening of our offices in Spain and Germany during the Mediterra period and the localization of after-sales services, we have become an important player in the European market. We already had high brand awareness and were a reputable brand in the industry, but we further strengthened our effectiveness in the markets by increasing our local support. Now, I can say that we are at similar levels of competition in the European market with brands known as our European competitors. We, as ARKEL, have started to be deemed as one of the manufacturers of Europe’s control system while respecting our competitors.

Our situation in the Turkish market has already been known. In this context, I would like to thank all of our stakeholders in Türkiye as ARKEL gained a strong position in the global market thanks to the great support from the Turkish market. In the future, we will focus more on localization efforts to maintain and further increase our current market share.

BY: You have products that can operate up to 4 m/s and 64 floors in the manufacturing of control panels. Will we see higher floor numbers and speeds?

CC: In fact, we have already achieved a higher number of stops and speeds in our product, ARMAXX. ARMAXX stands out as an advanced solution that offers much more than existing systems. With group control features, ARMAXX is a competent, innovative and unique system. It has powerful features, especially on the software side, and unlike traditional control systems, it also offers the user the opportunity to customize.

Although we have initially introduced ARMAXX as a high-end product, I suggest every segment, including the middle segment, take a look at this product. The product should not only be considered for needs such as high speed and a high number of stops. With its size advantages, stylish architecture, ease of use and customization options for low-stop and low-speed systems, ARMAXX is a solution that our lift operators in Türkiye should definitely consider.

BY: No company in our country produces automatic passenger guidance systems. Does ARKEL have any work in this subject?

CC: Yes, we are working on this. Especially, since the ARMAXX product I’ve just mentioned has a new structure and software platform, we have included the passenger guidance system in our plans as the next step in the design phase. We have initiated this project and have reached the completion stage now. We hope to launch it as soon as possible and share it with you.

BY: Do you have any work in other industries or on different product groups?

CC: ARKEL has no work other than the lift industry. We have the potential to bring our technological competency and knowledge in the field of R&D — which we have gained in the lift industry — to different industries with similar products in the future. However, this is an issue that can be totally evaluated in line with the strategic decisions to be made by our current investor and the needs that may arise in the future. We are not considering focusing on an area other than the lift industry right now. We love our industry, and our priority goal is to continue bringing innovative and attractive products into our industry.

BY: Lastly, let’s talk about your social responsibility projects. Do INNOVALIFT and ARKEL have any work in this subject?

CC: I assume that the contributions of ARKEL in the social responsibility area are appreciated by our stakeholders and associations in our industry and country. So far, we have done our best, especially in the field of training, to create technical training infrastructures and even provide direct training activities, and we will continue to do so from now on.

During the INNOVALIFT and LATOUR period, new studies will be added to the current social responsibility projects of ARKEL. LATOUR has a clear strategy and a strong commitment to sustainability, thus, ARKEL has started to shape its activities in line with these sustainability commitments. As a result, when the contributions from LATOUR are added to the social responsibility activities we have traditionally carried out, I can say that we will see a much more active ARKEL in the field of social responsibility in the future.

Get more of Elevator World. Sign up for our free e-newsletter.