“The Next Generation Secures Our Future Life”

Apr 5, 2023

Otis lead discusses the technical, economic and human future.

In December, Udo Hoffmann (UH), Central Europe Market Group lead and chairman of the Management Board of Otis Germany, based in Berlin, Germany, talked to your author (USB) about the “big picture” with a focus on trends in the elevator business in Europe.

USB: Mr. Hoffmann, could you please start with telling our readers about your personal and professional background.

UH: My paths at Otis have taken me to a variety of positions in several countries. My current job involves traveling a lot in Europe. Today is my last day in Berlin for another 17 days. I am constantly exchanging ideas with interesting people within my Market Group — be it in Warsaw, Poland, Vienna, Austria, or beyond. Nevertheless, I always make time for my wife and my daughter.

I was born in Eastern Germany. My father was also in the elevator business. I did my apprenticeship as a toolmaker already in the elevator industry. Later, I studied mechanical engineering and worked in construction — at Otis, of course.

Only once, I worked for a few months in another company. At INSEAD in Fontainebleau near Paris, I acquired the additional skills and tools for business administration tasks and built up and expanded my international network. Otis offers a lot, especially for employees. One could say, “Over the course of the years, we have invested in each other.”

USB: Today, we are talking about the “big picture” with a focus on trends in the elevator business in Europe. Could you please start with highlighting what moves our industry today — technically, as well as economically?

UH: Three things determine the business: firstly, the service portfolio. It is large in Europe, with Germany as a key player. Secondly, solutions for existing buildings. The population is getting older and older and is using buildings longer and longer. This is a “stomping ground” for innovations.

Thirdly, digitalization. In smart cities, elevators will no longer just go up and down a shaft, but they will connect people within and between buildings in a completely new way. We can already travel horizontally. But with the rise of digitalization, we will be able to use hundreds of millions of elevator data, drawing conclusions from them, and linking them in a meaningful way. In a department store, for example, we will measure traffic flows. People are already, nowadays, online more and more. So, one has to combine the data with their electric cars, for which thousands of charging stations are built in parking garages and private homes. Where will people work in the building and how will they get there? How will the last mile be designed? To answer these and many more questions, we can use the data from elevators.

USB: We can always learn from history. You have been in the industry for more than 40 years — what do you see as the biggest change in the past decades? And what was the lesson learned?

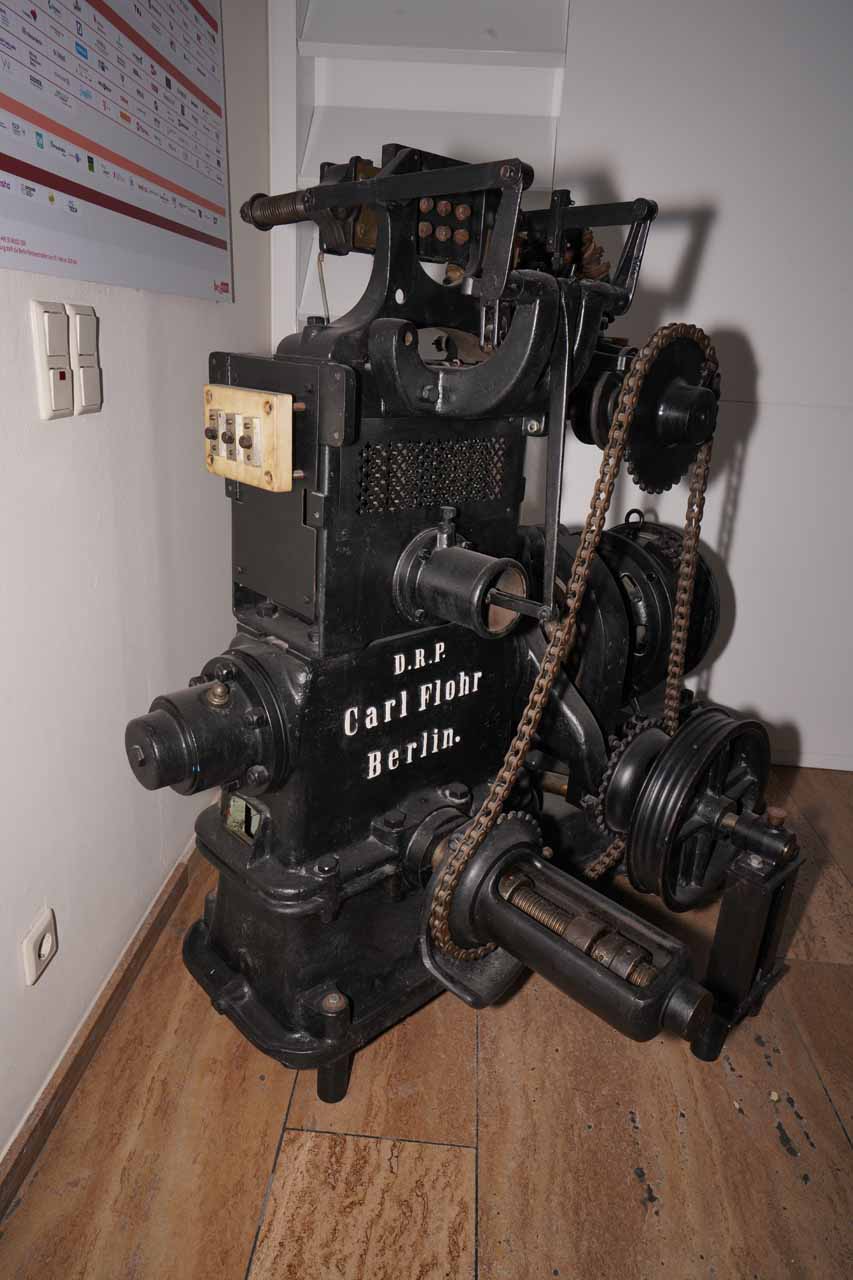

UH: The elevator business has always been a people business. Therefore, we are continuously in touch with people such as architects, technicians and, of course, passengers. And what were the results of this exchange? Larger drive machines, for example, with 500 to 900 mm traction sheave diameters. Or overspeed limiters with electrical and mechanical parts that no longer even exist today because digitalization has been a game changer. The innovations are jumping faster and faster to meet customers’ expectations.

USB: As digitalization is one of the biggest technical trends, which topics are you dealing with at Otis?

UH: We’ve been going digital for a long time. The key words here are availability, transparency and remote services. Today, a remote release of entrapped passengers is already possible in some cases. I would like to add a second trend here, which we must not forget under any circumstances: the reduction of our carbon footprint.

USB: In 2021, you launched the Gen360 platform. What are its technical features? How are these innovations received by the customers?

UH: One example of our advanced digitalization is certainly the Gen360 platform, where you can already intervene remotely in the control system. Sensors and cameras record data and images. Architects, in particular, benefit from its design with a low pit, which comes into play in underground garages, for example. Maintenance can be done in the car thanks to a foldable platform so that technicians no longer have to go up on the roof. This also allows for a reduced headroom.

The Gen360 platform has now been on the market for almost one and a half years and is already a preferred choice of customers. We have just signed a framework agreement with Goldbeck Immobilien (real estate) for its use. With the Gen360 platform, one aspiration is to learn from the data and share this data for building operations. The benefits of both sides can be tied together in this way. This is also where our eView screen comes in. For example, the operator can connect with passengers via two-way video.

The Gen360 platform is becoming one of our central products. Its IoT capabilities are currently still in demand and used differently by customers. However, demands in this area will continue to increase. A lot of data is already available today, but many customers are not yet aware of this. Ideas for linking data are increasingly emerging, and new solutions and business models are being developed.

USB: Another big challenge you mentioned — or trend as you called it — is sustainability. Otis publishes its second environmental, social and governance (ESG) report at the end of March. What is your concrete contribution to this topic?

UH: We take sustainability very seriously. Also, occupational safety and environmental protection play a major role for us. We work on these issues every day and invest in them. For example, we record what is produced when and where in order to optimize production processes and delivery routes; thus, we opened a new factory in Spain last year. For another example, we installed solar power panels on the roofs. Our factory here in Berlin is powered by 100% green electricity. Digitalization and remote services also help us to save energy. And not to forget our ReGen™ drive technology that — when combined with our efficient elevator machines — reduces energy consumption up to 75% vs. conventional elevators without regenerative drives.

USB: Let’s move from the technical to the economical side. What is the importance of the European market from the point of view of a global elevator manufacturer?

UH: From a global perspective, Europe is a key region for Otis. Globally, we generated around US$13.7 billion in sales in 2022. As I mentioned, service is a big part of the business, and our portfolio in Europe is huge. It is also a strategic territory for innovation: Europe is a mature market with customers and passengers constantly pushing us, especially on the environmental side.

USB: What are the impacts of the COVID-19 pandemic?

UH: I can’t praise enough how quickly our organization and IT enabled remote working. People arranged quickly with the new situation; teams were fully functional. Business has continued. Simply impressive! At the peak of the pandemic, some customers were concerned about letting our service technicians into their building. But with masks and testing, we got a handle on that, too. The pandemic showed the robustness of our service model and the resilience of our business: People were moved on without realizing the tremendous effort of the Otis staff in the background — also and especially during the pandemic.

The pandemic has been a driver for innovation, too, as the need for hygienic solutions in public space has never been that strong ever before. This was reason enough for Otis to offer such solutions as, for example, germ-killing blue-violet LED light in elevators and for handrails of escalators or touchless “buttons” to call the elevator or choose the floor.

Otis offers a lot, especially for employees. One could say, ‘Over the course of the years, we have invested in each other.’

USB: What impact has the energy crisis due to the war in Ukraine had?

UH: We have been transparent with our investors in how we are addressing headwinds in energy and materials costs. In general, there are currently different disruptions in business operations, but this is — at least in our case — not due to Ukraine. It’s important for me to add, that Otis continues to work in Ukraine. The service there continues to keep people vertically mobile.

The crisis has highlighted the responsibility we all have to reduce the ecological footprint of our products and activities. We have seen an increased interest from our customers on the subject. And even if elevators have been energy efficient for a long time and by design, modernizing or offering new efficient products allow us to contribute to a better management of energy resources.

USB: What short-term outlooks do you already see for 2023?

UH: Digitalization is taking the next step for us with connecting more and more elevators to our IoT solution Otis ONE. We have prepared ourselves for many changes in the communications network, especially in Germany. I also see the decline of COVID-19 as positive — or at least, we are getting used to it. The German government has set the target to build 400,000 new homes in 2023. That means thousands of opportunities for new equipment. We will continue to invest — we feel strong! We are not afraid of the future; on the contrary, we see opportunities. All market players have opportunities. Let’s stay positive and invest our brainpower in the question: How can we achieve our specific targets?

USB: One central question of the industry in the future, which we did not mention yet, is human resources related. How are we to find qualified staff? What can and what should industry do?

UH: Young people approach things differently. The attention span is decreasing. The speed of change is increasing. Young people have different values and ideas, and we as an industry have to deal with that differently. We have to be at the pulse of time; jobs have to be more interesting and more varied. Young people don’t stay in the same company for 40 years, like I did. Today, it is too late to recruit young talents when they are about to finish school. We have to introduce people to the elevator industry at an earlier age. Getting talent is hard work. We must and will train young people ourselves with apprenticeships and dual study programs. This is an investment that will pay off. The next generation secures our future life.

I also discuss this topic with my wife and daughter. Elevators are also still a male domain; but this is not a law of nature. We strive to have diverse teams that show high commitment and inspire great ideas to flourish. By 2030, we want to have achieved gender parity across Otis’ global executive positions. That revitalizes our company.

One example of our many activities to recruit and nurture young talent is our third annual student challenge, “Made to Move Communities.” The aim of this worldwide program is to spark an early interest in Science, Technology, Engineering and Math (STEM) as well as in mobility.

USB: Last, but not least, something personal: When you enter a lively discussion about a topic close to your heart, what would it be about?

UH: I would probably share my learnings from more than 40 years of professional life: You should always keep your feet on the ground and never forget where you come from. You should always look forward instead of back. Family is important. Change drives us forward; challenges drive us forward — you just have to be open to it. So, do what you enjoy; stay where you have fun; then, work evokes high spirits!

Get more of Elevator World. Sign up for our free e-newsletter.