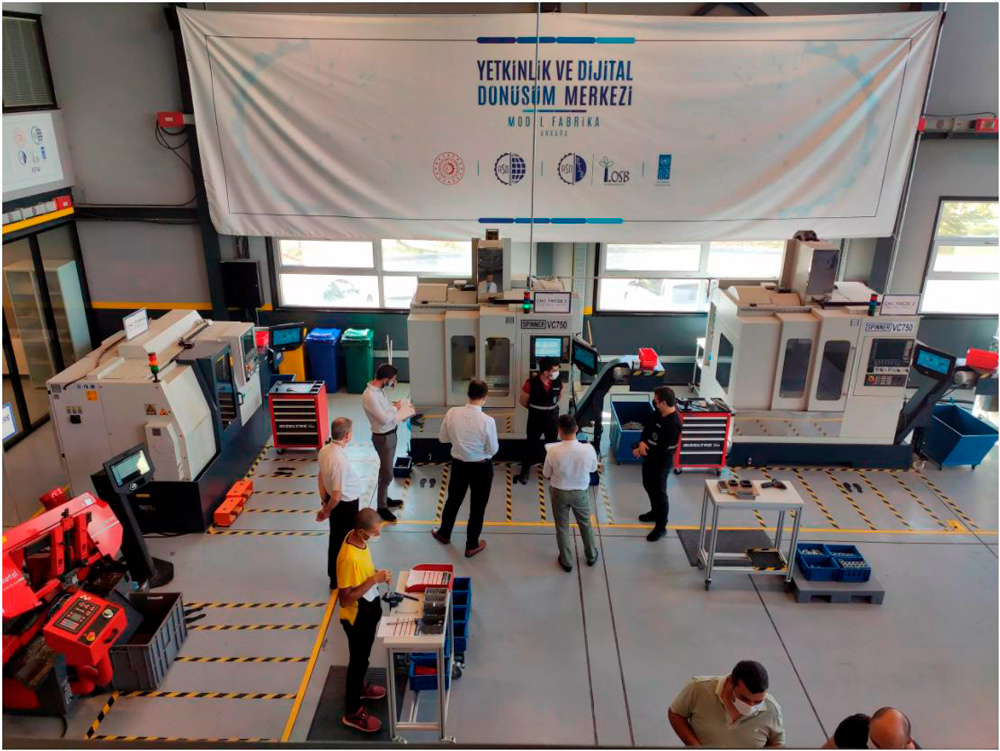

Last month, “ASO Capability and Digital Transformation Center” (ASO Model Factory), which was founded with the cooperation of the Ministry of Industry and Technology and the Ankara Chamber of Industry, in order to increase industrial efficiency and to accelerate digital transformation, held a meeting for the launch of the fifth Learn & Transform Program. A model factory will be established within one year in order to increase the efficiency of the enterprises in Kocaeli, which is an industrial city.

ASO President Nurettin Özdebir made a speech at the event held at ASO Continuing Education Center (ASO-SEM), underlining that there is an important efficiency problem in Turkey. Özdemir stated that a model factory is a “learning-by-doing” platform, and said: “Within this topology, we saw that model factory project was appropriate in order to understand and perceive the business simply and owned the project. We will be faced with a highly devastating competitive market in the near future. First, we need to do lean manufacturing in order to add Industry 4.0 to it. But, it seems that many enterprises have lots of ground to cover lean manufacturing. We have the opportunity to get ready for the devastating competition in tomorrow’s world and to be a real industrial society.”

Road Map for the Digital Transformation of the Industry is Prepared

Deputy Minister of Industry and Technology Mehmet Fatih Kacır stated that they have prepared the Road Map for the Digital Transformation of the Industry, which will be announced soon, in order to draw the frame for the things that will be done in the coming period.

919 Top Priority Products are Specified

Kacır stated that they specified 919 technological products, which are mainly imported by Turkey, for the Technology Oriented Industrialization Thrust Program. He said, “These products are the ones we import and spend 60 billion dollars on a yearly basis, with a current deficit of 50 billion dollars. Our target is to produce these products domestically and nationally as soon as possible.”

Model Factory will be set in Kocaeli Within a Year

In his statement for AA correspondent, Kocaeli Governor Seddar Yavuz said that a model factory will be establish in the city with the support of the Ministry of Industry and Technology. Yavuz said that they plan to manufacture high-tech products at the model factory. Thus, in addition to manufacturing, an important step will be taken in order to train qualified employees who are needed in the sector.

Yavuz said the Ministry has prepared a timetable, and the model factory will be incorporated and opened — within one year at the latest — and added, “Kocaeli is a city that uses high technology. We have SMEs. Purchasing these machines is difficult for the small and medium-sized enterprises. More importantly, we will also manufacture the prototypes of any products we aim to manufacture. Therefore, we will also perform their tests. Performing their tests is more important than manufacturing products. Many companies will also have the chance to test the products they manufacture.”

First Model Factory was Established in 2018 in Ankara

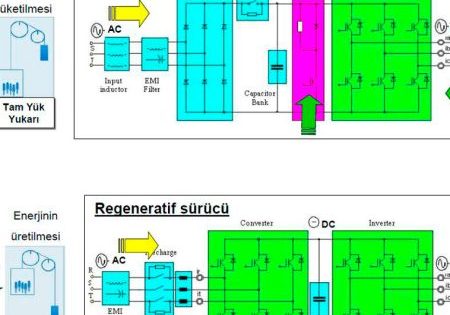

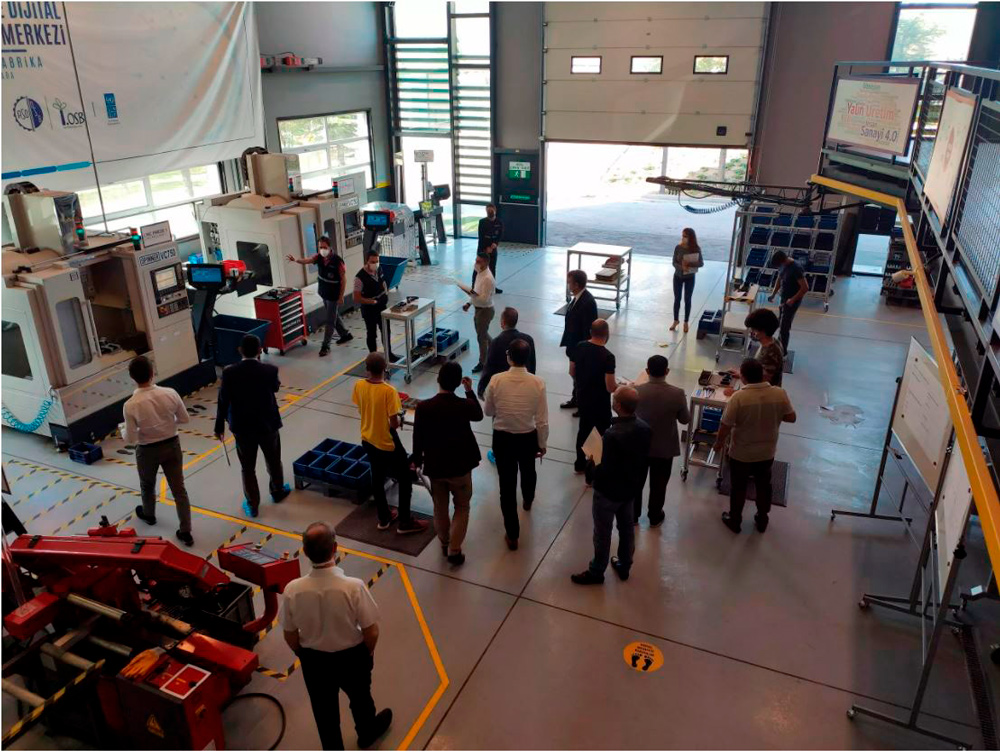

At ASO Capability and Digital Transformation Center (Model Factory), which was established on December 2018 with the aim of increasing industrial efficiency and accelerating digital transformation, training and consultancy services offered by using experiential learning methods and teaching operational excellence principles in a real production environment that offers freedom to make mistakes.

Model Factory offers applied training at the rate of 65 percent and corporate training at the rate of 35 percent. Experiential learning principles are adopted.

31 Percent Increase in the Efficiency of a Company in the Başkent Organized Industrial Zone

According to the results of the fifth Learn & Transform Program, the problems including delivery delays experienced by the companies located in Başkent Organized Industrial Zone, their high work in process inventories, and undefined and complicated production areas, were solved, while 31 percent increased in efficiency, 60 percent decreased in production flow time, and 27 percent saving in space were achieved. In another company with 29 employees, problems like mass production, too much buffer stock and delivery delays were solved, which provided 117 percent capacity increase, 38 percent savings on space and 66 percent decrease in products per man-hour.

Get more of Elevator World. Sign up for our free e-newsletter.