How recent ASME code updates and industry safety best practices are helping mitigate elevator hoistway hazards

by Kevin Brinkman

It happened in an instant.

In a video captured and shared online in 2021, three friends wanted to check out the flash flooding happening outside their apartment building in Omaha, so they got in the elevator and headed to the lobby. Unfortunately, the elevator stalled before they got to the lobby, and it started filling with water. As the water rose higher in the car, they climbed on the elevator handrails and called for help. Another friend was able to get to the lobby and, in neck-deep water, pry the hoistway doors open, allowing the three friends to swim out of the elevator and get to the building’s stairwell.

While flooding of elevator pits and water entering the cars may not be a common occurrence, there have been incidents during natural disasters where elevator cars have descended into a flooded hoistway. Fortunately, American Society of Mechanical Engineers (ASME) A17.1/CSA B44 Safety Code for Elevators and Escalators (A17.1), as well as the related codes developed by ASME, provide requirements for the design, manufacture, installation, maintenance, testing and inspection of elevators. These requirements are vital to protect the millions of people who rely on elevators every day to get to their home, workplace or other functions. The code also includes many provisions designed to help protect the men and women who keep those elevators running.

The 2022 edition of the code introduced new hoistway-related requirements to address the use of elevators in emergencies. New requirements were added to provide flood detection operation for elevators installed in a flood plain. These requirements are designed to detect a flooded pit and restrict elevator operation so the car or counterweight cannot descend below the maximum flood elevation. Another change allows the installation of emergency responders radio coverage equipment such as antennas into the hoistway to facilitate better communication for emergency responders who may need to use the elevators in an emergency to fight a fire or evacuate building occupants.

While code development is an important tool for improving elevator safety, there are other factors in play to ensure the safety of industry personnel.

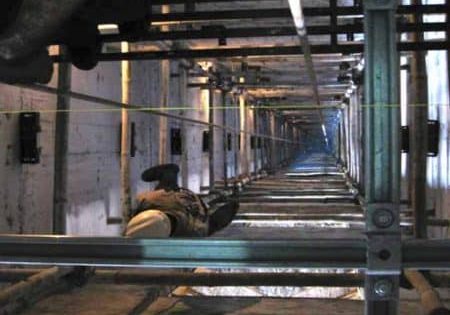

When work is being done in a hoistway, ensuring all industry safety practices are implemented is a critically important tool to mitigate hazards. Several recent code changes have focused on enhancing the safety of elevator personnel. One such change is the addition of full hoistway lighting. The code previously required lighting in the work areas in the pit, on top of the car and in the overhead if equipment was located there. The new requirement is for 50 lux (5 footcandles) throughout the hoistway. The lighting must turn on automatically during hoistway access and inspection operations. Switches are also required to be able to manually turn on the lights. Full hoistway lighting increases awareness of potential fall hazards when accessing the car top and of approaching objects anytime the car is moving. Additional lighting is helpful when performing maintenance or inspection throughout the hoistway. The lighting can also be used to satisfy the lighting requirements for fire service access elevators.

Standards for pit ladders were also improved. One change removed the exception to reduce the width of the ladders. The narrower width would not allow elevator personnel to have both feet on the same rung. This is important to allow a person to change their footing when stepping onto or off the ladder. Another change added a means to prevent the elevator car from moving if someone is on the pit ladder. The means can be sensors on the ladder itself or a guard with a means to detect when it has been removed. The new means provides additional protection if someone inadvertently fails to activate the pit switch prior to entering the pit.

NEII Leading the Way

While code development is an important tool for improving elevator safety, there are other factors in play to ensure the safety of industry personnel. Most elevator companies have their own safety programs with well-defined practices and procedures. National Elevator Industry, Inc. (NEII) and its members also work in conjunction with ELEVATOR WORLD, the National Association of Elevator Contractors (NAEC), and the National Elevator Industry Educational Program (NEIEP) to update and publish the Elevator Industry Field Employees’ Safety Handbook, which provides industry best work practices, including working in the hoistway. Updates are being made to the current (2020) edition of the Safety Handbook, and the new edition, scheduled for release in 2025, will include the latest technology and safety procedures.

Company safety programs and the Safety Handbook focus on practices and procedures for industry personnel. However, other trades often work around elevator hoistways during construction or modernization projects. NEII has developed a Hoistway Safety Initiative to educate other trades about the hazards in and around elevator hoistways. NEII’s Safety Committee developed construction site signage on best practice recommendations, including not using the hoistway as a trash chute, and awareness of the potential of falling objects, as well as slip, trip and fall hazards.

Hazards associated with elevator hoistways present a challenge, but NEII is leading through code development, industry best practices and education to mitigate those risks, starting with the safety codes. The code-development process is ongoing, and there are several changes being evaluated for future editions of the code, as well. Several of these are expected to be included in the upcoming 2025 edition, and others will take more time to complete. Hoistways will remain a key focus in code development: A safety challenge the industry is committed to addressing.

Kevin Brinkman is the senior director of codes at NEII. He has more than 33 years of elevator and lift industry experience, previously serving as vice president of engineering for ThyssenKrupp Access and National Wheel-O-Vator, as well as serving as an elevator consultant. Brinkman joined NEII in 2015, focusing on code development and adoption along with the safety of elevator workers and the riding public. He serves on several influential code development committees in his position and is a member of the ASME A17 Standards Committee for the Safety Code for Elevators and Escalators. Brinkman serves as chair of the ASME A17 editorial committee. He also serves on the International Code Council/ANSI A117.1 Committee, National Fire Protection Association 5000 and 101 technical committees and is involved in the International Building Code process.

Get more of Elevator World. Sign up for our free e-newsletter.