The family-run business focuses on employees and opportunities.

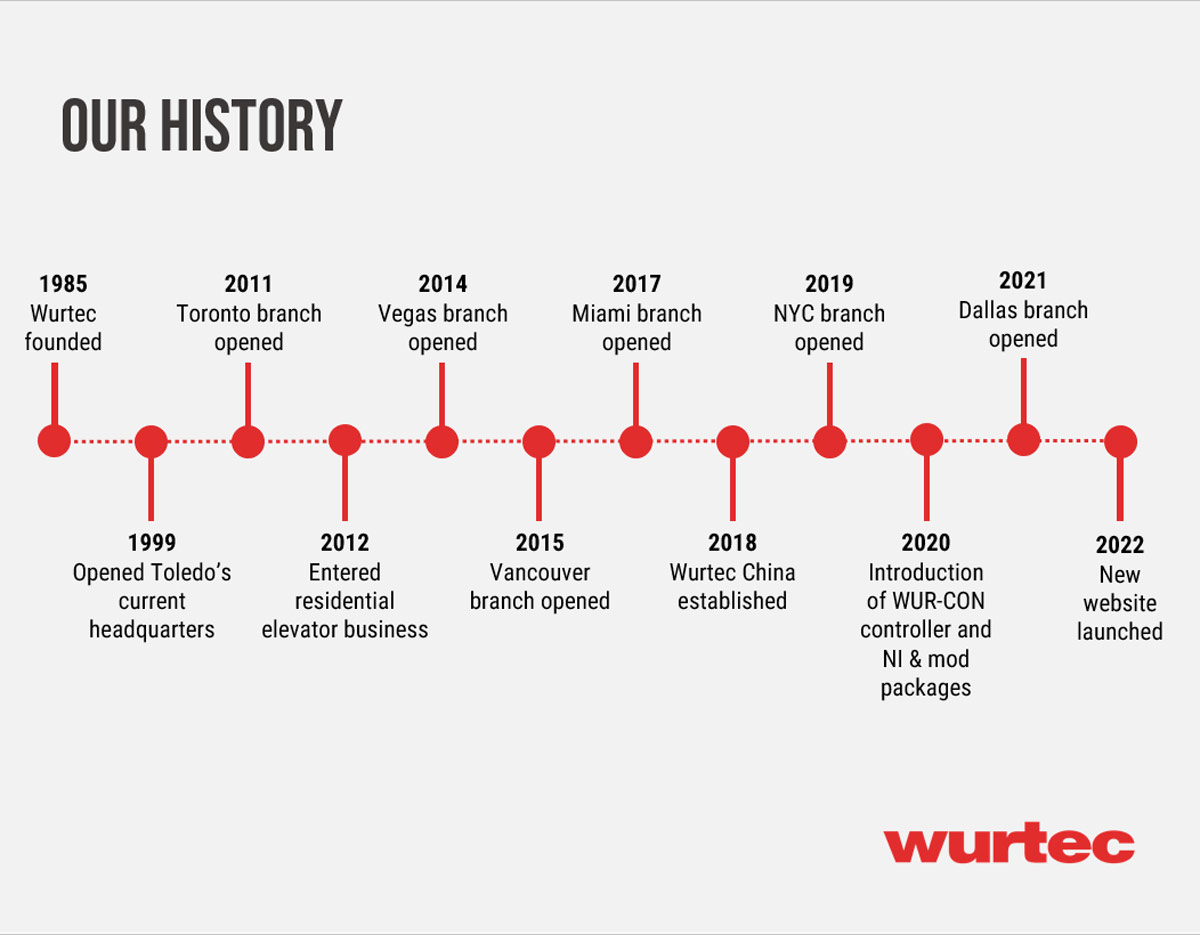

Wurtec was founded in 1985 in Toledo, Ohio, selling elevator tools and has since grown into a provider of complete elevator packages with seven additional locations across North America and beyond: Dallas, Las Vegas, Miami, New York, Toronto and Vancouver. Halfway through a 10-year strategic plan, Wurtec has a goal to hit and has pulled together the team to make this happen, looking for opportunities for growth and expansion along the way.

Your author (TBM) recently traveled to Toledo, to have a conversation the Wurtec leadership team and CEO Steve Wurth (SW) about the company’s background and growth, employee culture, current product offerings and running a family business.

TBM: Tell me a little bit about Wurtec and its progression from tools to what you offer now.

SW: Wurtec is a very opportunistic company. We really don’t know how to say “no” here. When we see opportunities, we tend to try to fill that void. We started out with tools. After the Americans with Disabilities Act (ADA) [of 1990] was passed, we saw an opportunity to get into emergency telephones. Then, there was another opportunity to get into what we call distributed products, like the harnesses and stuff that you can buy at the store, and then we just continued to grow.

In 2011-2012, a lot of things happened: We started our first branch, seeing an opportunity to get our products closer to our customers. We also bought a small residential elevator company out of Detroit, and that catapulted us into who we are becoming, which is a provider of elevator packages.

Customer service is also a big differentiator for us. We’re doubling down on treating our customer the old-fashioned way with customer service.

— Steve Wurth, Wurtec CEO

TBM: In the last 10 years, you have added a number of branches. What’s the thought process behind that?

SW: We’ve had a fair amount of success with getting our products closer to our customers, especially with cutting wire rope and traveling cable and servicing our rental fleet of false cars and climbers. This has reinforced our idea that branches are wanted and needed by our customers.

Wurtec always looks for a differentiator. It was easy to be different in the tooling line because we had the only tool around. When we sold only tools, the need for a branch was a lot less. When we started getting into more commodity-type products, then the differentiator became having branches and bringing the product closer to our customers.

Customer service is also a big differentiator for us. We’re doubling down on treating our customer the old-fashioned way with customer service. We believe that the path is through customer service, quality products and building steady, long-term products instead of trying to spin something up and make it look good tomorrow.

The other differentiator for us is our people. We place a high value on the people that work here. We work hard at it. I’ve always understood that having a strong culture is important. I just didn’t know how to describe it until we started using Entrepreneurial Operating System (EOS) in 2013. They convinced us that the way you describe your culture is by using core values, so we picked our core values in 2013, and they’re our DNA now. We use our core values to hire, reward and fire people. That’s who we are. We’re a team of 120 people (globally) that effectively all have those core values.

It shows in the fact that six out of the last seven years we’ve won the award for being one of Toledo’s top workplaces. It’s because we do care about our employees. We treat them well, and we treat them with respect. We try really hard to communicate with them. We try really hard to practice those values every day and provide consistency in the messaging. Our Core values do not end internally, we carry those values outside of the organization, and they are the driving force of how we work with our vendors and, most importantly, our customers.

The job of the leadership team is to create a strategy and a direction. Then, through those core values and proper communication, we try to get all 120 people rowing in the same direction. And we feel like if we can do that, we can really move the boat through the water. We’ve grown quickly since 2013, partly because of this and building energy behind the organization so everyone understands the vision we’ve created. We’ve got the right people on board.

I absolutely believe in our strategic plan. In my DNA, I am a long-term thinker, so I’m in this for the long haul. We have the luxury of being able to be patient with some of our projects and visions because we have time to build them.

TBM: How did you create your strategic plan?

SW: EOS has helped us a lot, and the leadership team has developed it. Before, we had a monetary goal, but we had no idea how to get there. We’ve still got about five years to chase down our 10-year goal, and now it’s well defined. We have multiple paths to our ultimate goal. We have created a lot of opportunity, and a lot of opportunities have come to us because of who we are as a company and the customer service we provide. It’s fun right now. It’s a good time in the industry. The organization is attracting a lot of attention. We’re getting people calling us now instead of having to chase everyone down.

TBM: How has the experience been in running a family business?

SW: Even in just having a successful family, there are challenges. You can only imagine when you take that challenge and then, the family also runs a business. It makes it an even bigger challenge. Like a lot of things in life, if you’re very intentional about it, it makes it easier. Our family is very intentional about both having successful families — No. 1 because I think that’s the foundation of a successful family business — and then having a successful business. When the family is healthy, it’s easy for the business to be healthier.

TBM: Tell me a little bit about your current product offerings.

SW: Rail installation and alignment equipment are the cornerstone of who we are, and then, hoisting is part of that. A lot of what we do is getting the elevator and rails and equipment up in the building or up in the hoistway. Those are tools because they never become a part of the elevator. When we say elevator components at Wurtec, it means it does become a part of the elevator, so, obviously, wall inserts, ladders and top car handrails.

Because of the ADA, we started building our own emergency equipment. The engineering team has also developed Wur-Com, a product that supports the new code requiring text/video communication.

A new venture for Wurtec is selling elevator controllers, and you’ll see more and more from us on this. We worked with a European company for almost two years to get the main piece compliant with A17, and now we’re building a full controller around it. Currently, we are building controllers for hydraulic elevators, and we have one designed for our winding drum residential elevator. The foundation of that product would allow us to go into traction cars if and when we choose. That’s a new product for us that’s beginning to, no pun intended, gain traction in the marketplace.

Our family is very intentional about both having successful families — No. 1 because I think that’s the foundation of a successful family business — and then having a successful business.

— Steve Wurth, Wurtec CEO

When we started to sell the controller, we found that people didn’t want to just buy controllers. They wanted to buy complete elevator systems, so in order to get our controller out in the marketplace we’ve started selling complete elevator systems. This is one of our products that is more reactionary than intentional. Admittedly, much of the system we buy from other people, but our team provides the full engineering package. We engineer the whole system so it works together, and we sell it as a system. We’re starting to get more and more success with that. And right now, we’re dabbling just in hydraulic elevators.

All of our branches are added-value branches or mini warehouses, if you will. We warehouse a lot of our products in each branch. Some of the biggest added-value operations that we perform there are cutting wire rope, cutting traveling cable and then recertification of our false cars.

We also have a long list of distributed products. We feel like our role is to provide customers with what they want, so we don’t do a lot of exclusive agreements. With customers, we have found that everybody wants what they want. We want to be the supplier that will give them what they want.

We’re high on standards, quality and certifications. We work to a lot of different standards. We believe in manufacturing as much as we can of our own products, but we want to be the last one that touches the product before it goes out the door. So we do final assembly on everything we do.

As far as our design software, we are probably leaning more toward the sophisticated side of being an engineering team, so we use a lot of animations in our design process and FEAs (finite element analysis), which are a computerized way of testing a product before we physically test it. We spend a lot of money on software so our team can be as fast and nimble as possible.

That’s who we are as a company. We have some pretty aggressive growth plans in our strategic plan, and the good Lord willing, you’re going to see bigger and better things out of us in a few years.

Get more of Elevator World. Sign up for our free e-newsletter.