Your author highlights his company’s role and factors driving the initiative.

Many companies are expanding manufacturing across India. Increasingly, we see elevator companies assembling entire elevators in India. This is partly driven by a growing vertical-transportation (VT) market. The elevator business is expanding here, and there comes a point when any market is large enough that it makes sense for a manufacturer to build a factory within India. Domestic manufacturing is also partly driven by the government’s “Make in India” campaign. Improving India’s domestic manufacturing base is certainly a worthy goal, and, overall, the initiative is making great strides. But there is a big difference between the final assembly of a product like an elevator and manufacturing the components that comprise it.

One big problem facing the “Make in India” initiative is the ongoing public perception that products manufactured abroad are of higher quality. In many sectors, this perception is out-of-step with reality. Part of the problem for Indian manufacturers is the need to meet international norms and standards. If such standards are not met, Indian-manufactured products will always be less appealing than those of the international OEMs. Even if they are perfectly capable, Indian manufacturers are often perceived as being unable to meet international standards. The government can really make a difference on this issue.

What Can the Government Do?

Government initiatives are good, but India is still well behind in meeting international elevator standards. IS 14665 is being replaced by IS 2021 (a modified version of ISO 8100-1:2019 and 8100-2:2019), which is on par with international standards, soon. Indian manufacturers need to follow these standards when they manufacture and sell domestically. To make a real difference in the industry as a whole, however, standards must be made mandatory by the government. And it’s about more than just safety. We need quality standards, too. In Europe, for example, elevator products require the approval of many authorized bodies. We should have similar bodies here for elevator products certified by the government. Currently, if an Indian elevator OEM wants a component that definitely meets international safety and quality standards, it knows this will be the case if it buys it from a European manufacturer. If it buys it from an Indian manufacturer, however, it has to research which international standards it meets. The rigorous application of standards at the government level would be the best way to deliver domestic and international confidence in Indian elevator component manufacturing.

What Can Manufacturers Do?

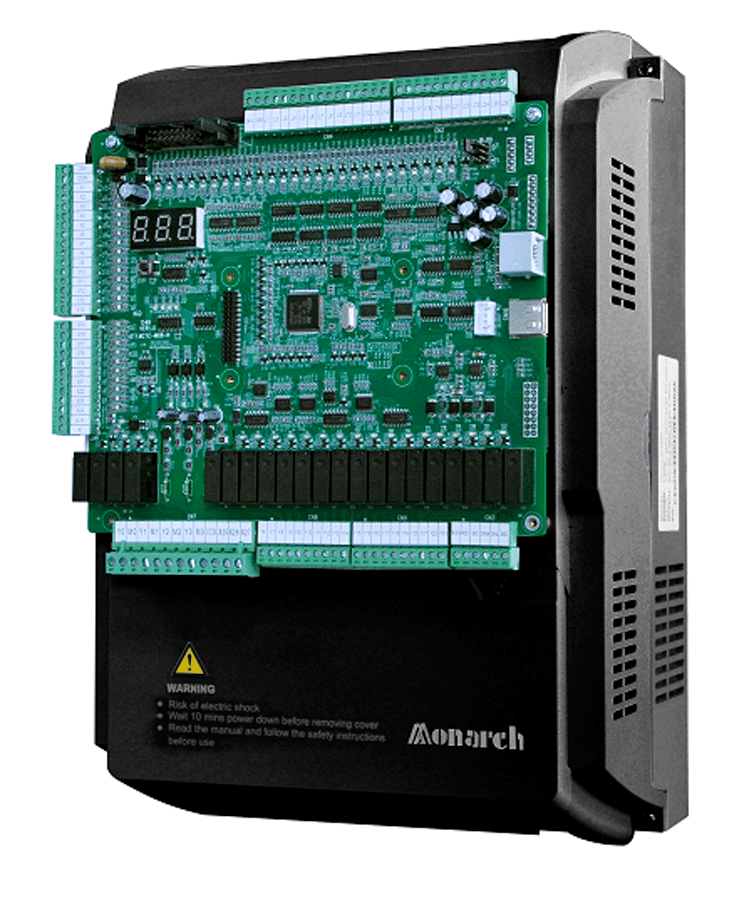

It is not all up to the government. Our company, Inovance, entered the Indian market in 2012, and we immediately recognized the importance and relevance of “Make in India.” We are responding to it in every way we can. One of our early actions was to set up local R&D facilities. We complemented our Indian R&D teams with local strategic managers (such as myself) to monitor the needs of the Indian market. This resulted in Inovance developing India-specific products like the NICE1000+ integrated solution for elevators (ELEVATOR WORLD India, 3rd Quarter 2020), which is EN81-1-A3 ready and designed by our local teams.

The rigorous application of standards at the government level would be the best way to deliver domestic and international confidence in Indian elevator component manufacturing.

India is one of Inovance’s largest and most important markets. As we grow our market here, we will be able to invest more in manufacturing. We have already increased cab building locally.

Realism is important too, though. For me, “Make in India” doesn’t just mean that everything bought in India should be made in India, because India benefits greatly from importing high-tech products. It is unrealistic for every country to make everything, so many sectors have a few suppliers that supply the whole world. With time, some of these suppliers will be based in India.

To return to elevators, Inovance was one of the earliest to bring gearless technology to India. Ten years ago, most Indian elevators were geared, and Indian elevator companies lagged in the controller area. They couldn’t produce the right controller to control a gearless application. The selection of gearless machines was limited and priced significantly higher than its counterparts. Innovation has driven the market forward considerably. Now, almost 50% of Indian elevator OEMs use gearless technology. Ultimately, more and more foreign-manufactured innovations like this will be manufactured domestically as their market share in India grows.

India needs to find its niches. I would like to see a strong and globally confident Indian manufacturing sector in which Indian manufacturers dominate certain niches and develop a large international export base. This takes me back to my initial point about standards. For Indian companies to compete globally, the country must establish a reputation alongside Europe and North America as being at the forefront of high quality and safety.

This article incorporates views expressed by your author during a panel discussion on the challenges and opportunities of procuring “Make in India” components held on March 20 during India’s inaugural virtual business conclave-cum-expo for the VT industry, Global Lift & Escalator Expo 2021 Virtual.

Get more of Elevator World. Sign up for our free e-newsletter.