ThyssenKrupp supplied escalators and elevators to this Warsaw office and commercial building.

Wolf Marszałkowska is a high-end office and commercial building located in Warsaw, Poland, and became operational in June 2010. The name of the building is derived from the street it is located on – Marszałkowska Street. Designed by Kuryłowicz & Associates Sp. z o.o., the building is 43 m high and offers more than 11,000 m2 of office space, and 3,300 m2 of commercial space. Owner and investor Wolf Immobilien Polen S.A. is known for its invo lvement with high-standard projects featuring up-to-date technical solutions.

Vertical Transportation

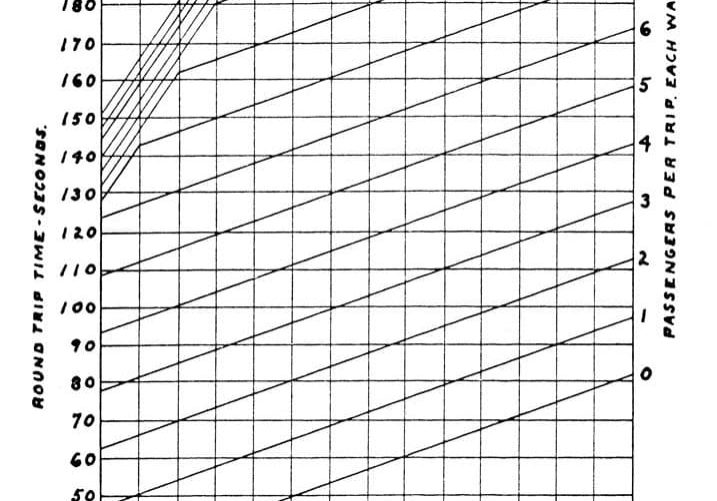

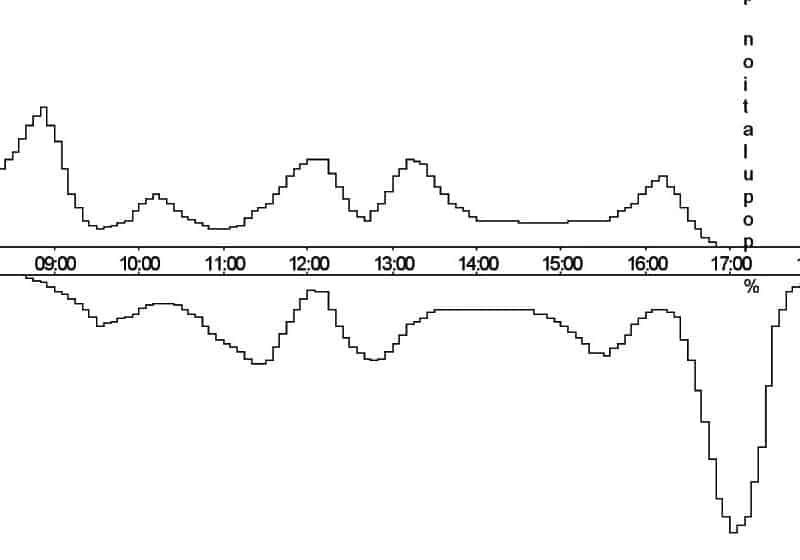

ThyssenKrupp Elevator sup-plied six Velino Extra escalators and eight elevators. The elevators serve 17 floors (five under and 12 above ground). For the most efficient work, the lift installations were divided into groups. Four machine-room, gearless lifts with speeds of up to 3.5 mps were in-stalled in the main building, and two Evolution lifts with speeds of up to 2.5 mps were installed in the second core of the building. In addition, two secondary lifts with standard control systems were installed in other parts of the building. Two of the elevators are firefighter lifts and are fully compliant with the EN 81-72 standard.

The six Velino Extra escalators are located in the main atrium of the building, with two situated in front of the main entrance, connecting the ground floor with the office lobby two floors above. The latter two are cladded with concrete plates that are fixed directly to the truss. All six escalators are equipped with advanced control functions – variable voltage frequency drives, energy-saving options, remote control and monitoring integrated with a building management system.

At the design stage, the architect was able to estimate the proper weight of the cladding, which allowed for the designing and production of the truss before choosing a designer and final contractor. This helped deliver equipment to the construction site at the appropriate stage. Special construction of the truss also allowed the architects to choose cladding type from a wide range of materials. Initially, the use of alabaster or another type of stone was considered, but due to their fragility, the final decision was to use prefabricated panels of rein-forced architecture concrete. Installation Process

The escalators were delivered in two pieces in June 2009, immediately after the main concrete structure of the building was completed. Installation of each part of the escalators was coordinated by eight people. The operation was performed at night to minimize the number of people working in the building and to re-duce traffic problems on one of Warsaw’s busiest streets.

The equipment was assembled inside the building and protected by multiple layers of foil, OSB plates and tarpaulins. This protection was crucial due to the number of construction workers close to the units and potential of rain coming through the open roof and façade. The layers were removed and the final cladding installation started after construction work on the roof was completed in October 2009.

Due to the heavy loads, it was necessary to install the plates evenly so the construction was even and symmetrically loaded during the entire process. The cladding installation was completed in January 2010. Special lighting was installed at the bottom of the cladding and a strip of LED backlights were placed along the escalator handrails.

Get more of Elevator World. Sign up for our free e-newsletter.