Outdoor panoramic lift installed at the Shenzen International Trade Building.

by Guanglai Liu, Wei Che, Xiangyang Cao, Wei Shen, Bin Yu, Zhangcheng Le

Zhejiang Giant M&E Co., Ltd. adheres to the development history of Giant Enterprises and was founded in 1951. It began to produce lifts in 1978 with more than 40 years of experience in elevator equipment. It engaged in the elevator component business in 2005 and officially established Giant M&E Co., Ltd. in 2007. With renowned design capabilities and unique process skills, it provides panoramic cabins, decorative cabins, glass doors, fire-proof doors, home lifts and technical solutions. Some products are exported to foreign countries and are highly favored by local customers.

Below, your author introduces an outdoor panoramic lift produced by Giant M&E Co. – “Tianzun.” The lift is installed on the first building of China’s reform and opening — the Shenzhen International Trade Building, with three interconnected lifts leading directly to the revolving restaurant on the top floor.

The building was the earliest comprehensive super high-rise building in China. It is known as the “tallest building in China” and has received many state awards. When the building was put into use, the lifts came from a foreign company.

Due to its location in a coastal area, the lift running in an open shaft and years of wind, rain and sun exposure, it lost its charm. The owner then put forward a renovation demand for the lift. In an era of product supply shortages, functional satisfaction is the first element. However, in today’s fiercely competitive market, product appearance, price, quality and service are all indispensable factors that reflect product quality. The lift cabin, as a carrier of “zero distance contact” with passengers, has become key to the implementation of this project.

On behalf of the manufacturer, our company is responsible for the cabin. Soon after receiving the task, our engineers the site.

The building wall is composed of several trapezoidal geometric vertical structures with a very specific sense of volume, giving people a solemn and atmospheric feeling. The top floor is a circular revolving restaurant, which is an ideal place for tourists to dine and sightsee. The main parameters of the lift are shown in Table 1:

| Rated load capacity | 1500kg | Rising height | 132.4 m |

| Rated speed | 2.5 m/s | Shaft type | Open shaft |

| Overhead height | 6.45 m | Quantity | Three units |

| Pit depth | 2.5 m | Control method | Interconnect |

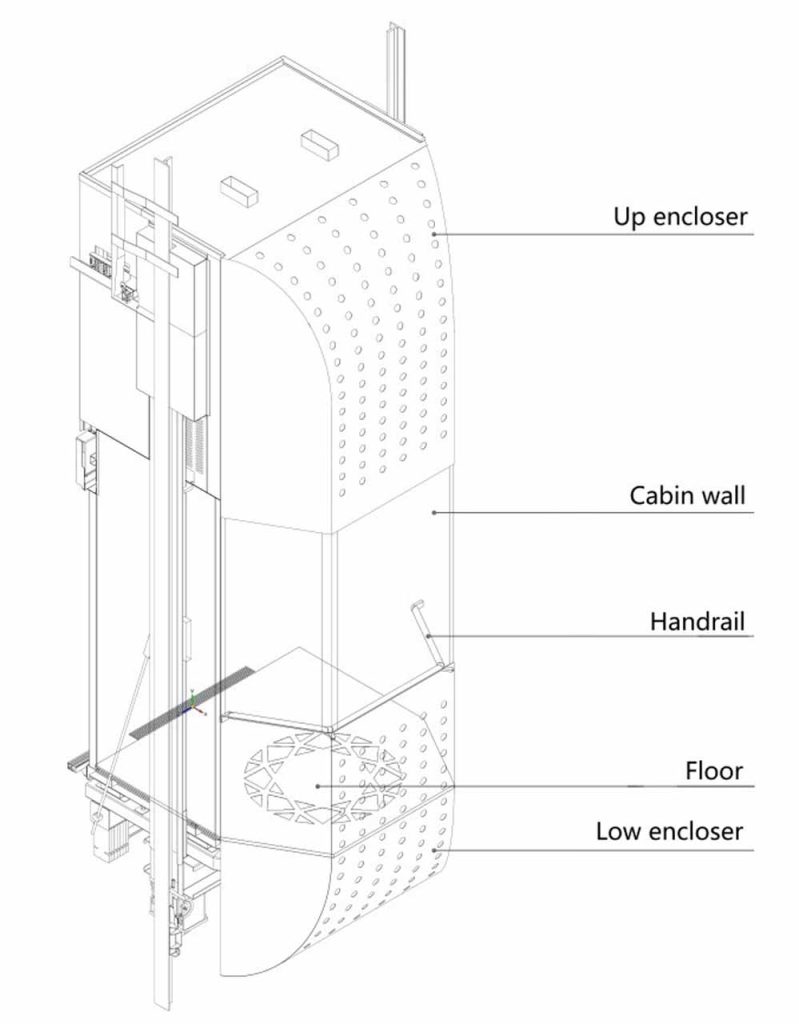

Analysis of the Old Cabins (Figure 1)

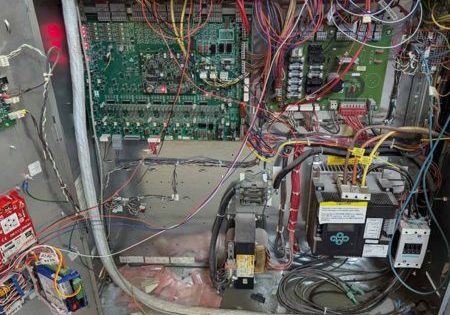

The lift follows the layout of the diamond shaft, and the outer cover of the cabin is composed of a rectangular box and two inclined triangular prism geometries. The slanted face of the up cover is made of glass. Due to long-term exposure to the outdoor environment, it is often exposed to direct sunlight, resulting in severe dust accumulation. The frames around the partition glass are fixed with frames, and the columns and crossbeams are crisscrossed horizontally and vertically. In order to prevent exposure to sunlight and rain, multiple layers of glass glue were applied, greatly affecting the experience of sightseeing and riding.

The low cover was equipped with acrylic panels that were too large in area and could not be fixed by detachable structures. Over time, they were severely deformed due to exposure to sunlight, making lamp maintenance even more difficult. Once a lamp is broken, the visual beauty of the low cover is greatly reduced. During our on-site survey, the one lamp on the low enclose of the two lifts had malfunctioned. The low ceiling did not effectively utilize the height space of the shaft, giving people a sense of oppression. There is a certain height gap between the handrail and the skirt, which may increase fear for some passengers, and the appearance is too cluttered.

Industrial Design of New Lift Cabin (Figure 2)

After on-site inspection, we wanted to minimize the disadvantages of the original lifts and put our industrial design and process expertise to the test. The overall design of the building is dominated by block surfaces, and the interior incorporates elements of a circular revolving restaurant, reflecting its elegant and luxurious characteristics. During the day, the lift cabin utilizes the refraction of sunlight to shine brightly. At night, the lift cabin runs with the help of exterior lighting, which is dazzling and eye-catching, making it a beautiful sight in the bustling urban area of Shenzhen whether day or night. A key feature of the lifts is that they run in an open shaft without a curtain wall and reach the top floor at a high speed. Therefore, the design of the lift cabin must take into account the characteristics of rain resistance, sun protection and marine climate corrosion, as well as safety and convenience during maintenance.

Our industrial designers designed cabin solutions for the project. Among them, the “Tianzun” solution, as shown in Figure 1, received the most votes and unanimous recognition. Its creative characteristics are as follows:

Source of Inspiration

The name “Tian Zun” means “Zun,” an ancient Chinese aristocratic wine vessel. Named “Tianzun,” it not only symbolizes a sedan directly inserted into the clouds, but also combines the unique business characteristics of a revolving restaurant that allows for the smooth drinking of wine. The key is that the exterior design of the lift cabin is similar to an ancient wine vessel.

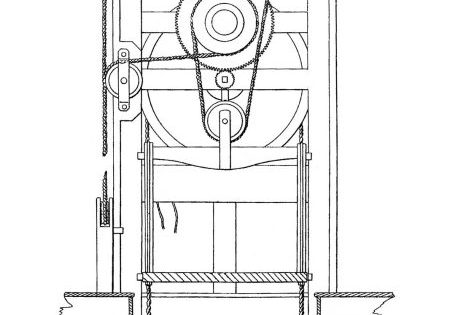

Lift Civil Layout

The goal was to completely maintain the structure without affecting the existing shaft conditions and make its appearance consistent with the exterior wall style of the building.

Design Concept

Borrowing the concept of sports cabin exterior design, the overall shape of the cabin is streamlined, which can effectively reduce airflow resistance during high-speed operation of the cabin, making the riding experience more stable and comfortable. It can also quickly divert rainwater and enhance rain and moisture-proof functions. The creative design of the cabin was designed to have a cabin sunroof, which allows passengers to have zero-distance contact with the outside world. Due to the limitations of elevator standards, the lift glass sunroof design was cancelled during the implementation process.

Cabin Design

The description of each component is shown in Figure 3.

Up and Low Encloser

In the diamond-shaped shaft, in order to balance strength and softness, the lift design cuts the up and low ends of the diamond-shaped edges through elliptical arcs to obtain two elegant outer enclosers. The material design uses mirrored stainless steel that, under the reflection of sunlight, complements the glass curtain walls of surrounding buildings, complementing the modern and beautiful urban setting. The appearance of the cover becomes the finishing touch of the entire lift design. The top cabin wall is equipped with a cavity to accommodate air conditioning, cabin roof pulleys and guide shoes, allowing maintenance personnel to work safely and comfortably while also serving as a protective fence. The low cover utilizes a semi high viewing surface to increase the height of the low skirt, resulting in a symmetrical relationship between the up and low outer enclose, making the appearance neat. The minimalist appearance is not only based on aesthetic considerations, but also on minimizing welding seams to prevent deformation, detachment and water accumulation. The up and low enclosers are welded and polished as a whole.

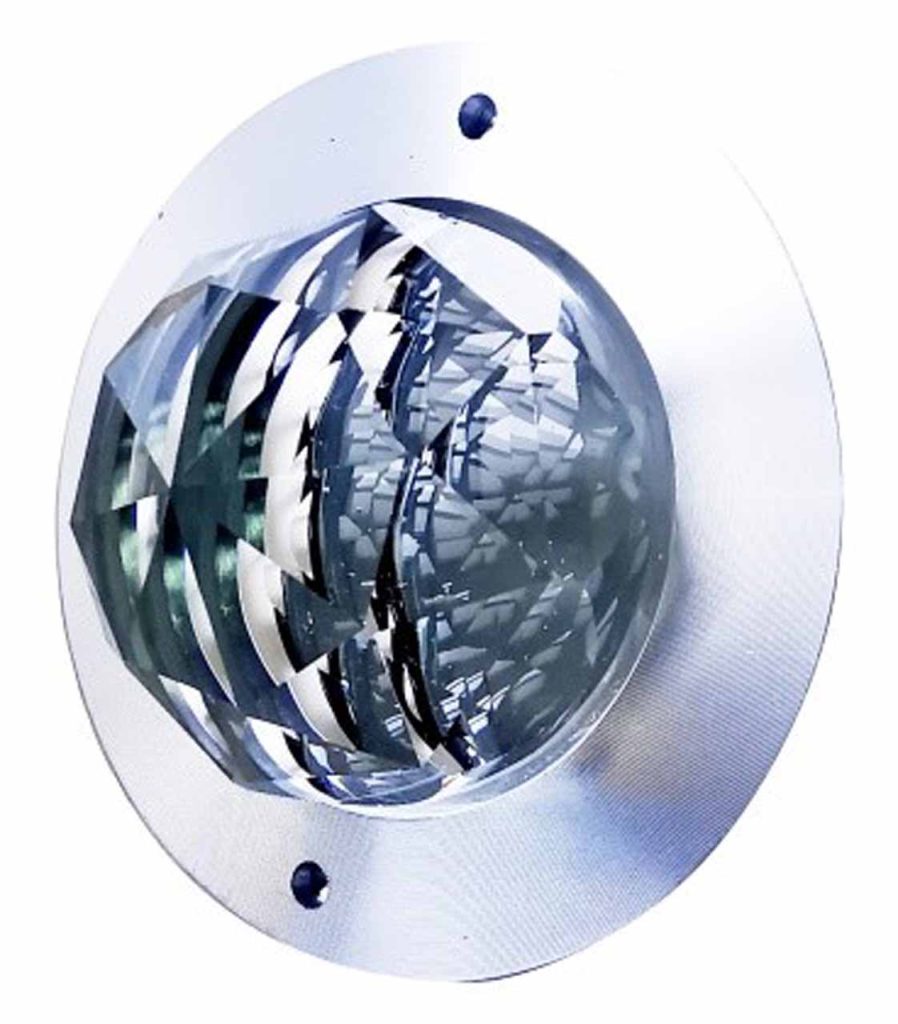

The up and low lamps have unique features, and the circular lamp column was planned to use six strip lights. However, due to limitations in technology, maintenance and project progress, it was changed to a tube light scheme. Spotlights (Figure 4) form light strips through arrays, which not only facilitates sheet metal processing and ensures substrate strength, but also facilitates waterproofing and maintenance. Even if one or two spotlights are broken, it does not affect the overall lighting effect when viewed from a distance. When the lift runs up and down, the spotlights naturally string into strips of light, giving people a feeling of flowing clouds and water. Each diamond-shaped spotlight emits a brilliant light, making the lift appear dazzling in the night sky.

Cabin Wall

The side cabin wall design draws elements from the exterior wall design of luxury specialty stores, using artistic glass and LED light strips. It increases the brightness of the cabin interior, making the entire cabin transparent and beautiful both inside and out. The outer side of the lift cabin is equipped with pre-assembled stainless steel cover plates. To make the elevator cabin more concise, an integrated rotary control panel is used on the front wall.

Handrail

The handrail adopts a new technological solution to ensure precise interface and installation. Through special surface treatment, it can quickly and automatically eliminate fingerprints and sweat stains. Raising the height of the panoramic skirt can not only eliminate passengers’ fear of heights and discomfort, but also make the handrail placement more reasonable.

Ceiling and Floor Design

The revolving restaurant is a signature feature of the building, so a bird’s-eye view of the circular restaurant became the creative inspiration for the ceiling and floor. This circular design is like a restaurant totem embedded in a hexagonal structure. The staircase design not only facilitates the maintenance and replacement of lights, but also enriches the top structure. Therefore, the exterior design of the lift cabin caters to the structural form of the building’s exterior façade. Its interior design is in line with the architectural style of the top floor of the building.

From outside to inside, this plan came together to realize the unique lift cabin design for this building. All appearance effects were achieved through clever structure and strict craftsmanship. To ensure the smooth achievement of all the above goals, engineers from technology, process, testing and quality carried out a series of factory trial production, on-site simulation and testing verification work. The key points of the project are as follows:

- Design of water-guiding and drainage schemes for the cabin wall

- Rainproof and water-guiding design of the steel wire rope and pulley on the top of the cabin roof

- Linkage with control system, drainage design for lift reaching base station

- The selection of materials for each component of the lift cabin affects its anti-corrosion, acid and alkali resistance performance

- Rainproof design of the panoramic glass in the lift cabin

- Developing waterproof lights, which meet the function of changing lights inside and outside the cabin

- The ceiling can be flipped down while also meeting the functions of changing lights and cabin roof escape windows

- On-site installation and protection of big mirror stainless steel

“Tianzun” was ultimately delivered with high quality requirements, becoming a art of the beautiful scenery of the International Trade Building and receiving high praise from customers.

Get more of Elevator World. Sign up for our free e-newsletter.