Wurtec uses input from mechanics and customers to continue to innovate new products and processes.

Wurtec’s business concept – to provide tools and elevator products today and for the future – continues with more success and many new ideas, according to Wurtec founder Steve Wurth. Wurtec began in 1985 in Toledo, Ohio, when Wurth developed field solutions for Haughton and Millar Elevator.

The company has grown steadily to its modern-day position as an established provider of solutions and products for the elevator industry, such as field tools and testing equipment. Serving multinational and independent contractors globally from its Ohio headquarters, Wurtec delivers tools, equipment and solutions to elevator mechanics.

Upon Wurtec’s founding, the mission was to provide elevator professionals with improved tools and products for the service/repair, modernization and installation of elevators and escalators. Quickly becoming a go-to source for field knowledge, Wurtec shared and compiled knowledge gained directly from mechanics on the job during site visits and customers during brainstorming sessions. From these experiences, Wurtec saw that even the best-built tool, despite being competitively priced, was useless without mechanics having the knowledge and methods to use it effectively.

Over time, Wurtec saw it could meet both independent contractors’ and OEMs’ needs across field operations. This led to improvements in the design of specific components, with the goal of improving employees’ field effectiveness. An engineering department of one slowly grew to today’s team of more than 10 engineers, who develop new tools, products and processes.

Wurtec recently expanded its geographic footprint to improve availability and access for customers across North America and throughout the world. Doing so has also allowed Wurtec to handle new products such as traveling cable, wire rope and spare parts. This has increased the knowledge base of Wurtec engineers and opened up new areas for potential product improvement and design innovation.

In the early years of Wurtec, several popular tools and products were developed that are still manufactured today. These included rail installation and alignment tools, plumb lines and tensioners, hydraulic-jack alignment kits, rail pointers and rail blocks for hanging and blocking/suspending cars. These products were highlighted and complemented by the Wurtec False Car (ELEVATOR WORLD, June 2014), a system engineered and designed for safety that has been used in mid- and high-rise projects around the world. The well-known, industry-standard False Car featured ease of assembly and use that was ahead of what was available in the market at the time.

As Wurtec moved into its second decade, it embarked on a second wave of product development and engineered products. This included a successful move into engineered electronic and electrical products. Wurtec emergency Americans with Disabilities Act communications systems, featuring improved functionality over existing ADA phones, were successful and continue to be a strong and evolving product line. Hitting a productive stride, Wurtec engineering/design and product-development teams continued to introduce products and solutions, including:

- Wall inserts with standardized hardware for use in all types of shaft construction with supporting engineering/load-rating documentation

- Pit ladders with configurable and modular design, able to be shipped via standard UPS

- Rail blocks and lifters designed to improve safety and efficiency during installation

- Sleds for installing wire rope, shortening clamps and re-roping tools, allowing for more cost-effective and safer work with wire ropes in the hoistway

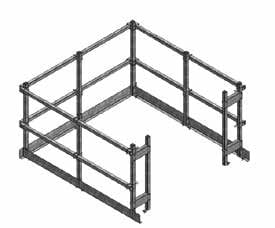

- Top-of-car handrails with modular, standardized design for easy installation and application across cars of all sizes

Wurtec’s key highlights in its third decade include load-weighing, rope-tensioning and alternative load-testing equipment and measurement tools that were brought to the market through a partnership with Henning GmbH. The addition of new distribution points improved accessibility to wire rope, traveling cable and other Wurtec products for customers across North America. The company provides technical support to customers for these products.

Among Wurtec’s latest innovations are an electronic notification device and the Beeper Box, which provides audible alerts to installers warning of the dangers of moving counterweights and installation platforms. A partnership with a microprocessor and security-savvy manufacturer from Israel led to the introduction of iCEP (EW, August 2014), a standardized, keypad-style car-operating panel (COP) interface that boasts a modern look and is easy to install in standard COP configurations.

Wurtec engineers recently released a new rail straightness testing device for inspecting the quality of rails at the time of installation. This tool ensures only quality rails are installed and avoids costly ride-quality evaluations and corrective actions later. Finally, a new high-speed capstan for faster, more efficient rail lifting during installation of higher-rise elevators has received positive reviews from customers.

Wurtec is moving into its next 30 years, and the team looks forward to continuing its mission of using industry knowledge, customer partnerships and in-house expertise to provide designs and ideas that lead to new tools, products and solutions to help customers achieve success and safety on the jobsite.

Get more of Elevator World. Sign up for our free e-newsletter.