Managing risk in the post-pandemic office

Almost a third — 31% — of Brits want their professional life to return to exactly the way it was prior to the pandemic, shows a YouGov poll on behalf of Indeed. With offices and cities gradually opening up, Sheridan Lifts, a family-owned U.K.-based independent lifts company, provides lift safety and hygiene tips for those returning to work.

General government regulations imposed with respect to offering employees an environment as risk-free as possible refer to minimising everything that’s unnecessary, from visits to contact, frequent hygienisation of oneself and communal areas, and social distancing.

An Institute of Workplace and Facilities Management poll, however, shows a general distrust in terms of attitudes from workers, as almost a third of respondents (30%) do not believe either their bosses or offices are prepared for ensuring a safe return. In fact, 41% doubt how realistic maintaining social distancing is, while nearly half (49%) believe cleaning standards will be hard to enforce and maintain, and only 37% feel protected by their employer.

Chris Chadwick, service director from Sheridan Lifts advises:

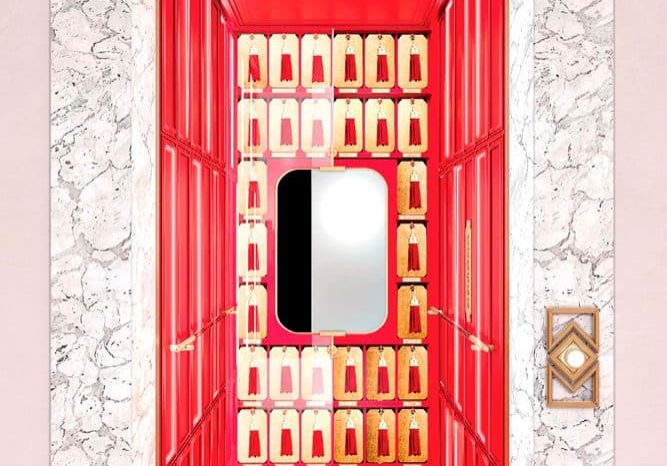

“If a business is about to re-open following the easing of U.K. pandemic restrictions, and the company has a lift in the building, it might be time to examine the existing lift-maintenance agreement. Are you getting value from it? Are you experiencing too many call outs? If so, it could be time to test the market. This also applies if a business has a lift that has possibly been out of action or de-commissioned for some time, as these can be modernised, and the aesthetic appeal of the lift car can be enhanced.”

Maintenance Requirements

According to the Lifts and Escalator Industry Association (LEIA), lift owners/duty holders are still liable if a proper lift maintenance agreement is not in place to ensure user safety. This means that the paperwork has to be up to date for the lift to be compliant, and delayed checks should be carried out or, conversely, they should be booked early to stay aboveboard.

Wear and Tear

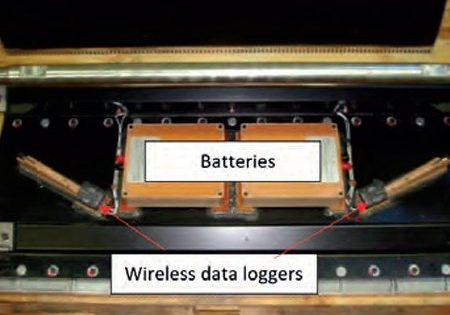

Equipment should only be put back in use after a shutdown but once a full analysis is done as, depending on the mechanism of the lift, certain parts can degrade after prolonged standby periods and might require replacing. Lifts that run more often with fewer people are bound for accelerated wear and tear.

Traffic flow

Planning ahead is key to risk management. Traffic flow should be constant by providing access to stairs, and an adequate number of lifts should alternate between workers. Ideally, one-way routes should be available in both cases, and peak times identified so that an appropriate number of users can go in one lift car at any one time. This can also be ensured with extra signage: labelling the maximum number of people permitted to ride at one time is highly advisable, as is adding floor indications if the car is spacious and instructions become unclear. While some consider changing door dwell times, this should only be done with the help of lift specialists, as they can also determine how to maintain accessibility for those with disabilities as well.

Visible and Clear Instructions

Simplification of all movement processes is a must, and this can easily be achieved by minimising the effort or time required in following instructions. Some recommendations would be removing obstacles and distinctively marking the disembarking area, as well as separating it from the boarding queue. This will ensure minimum contact, which could be cut down further with a plexiglass between the two if the space allows.

Cleaning

While constant cleaning of all inside surfaces is highly recommended, any use of excessive liquids (implicitly cleaning supplies) might damage the equipment. Alternative solutions, such as touchless buttons and lift-decontamination protective coatings on touch-points, are advisable (and cost-effective, as layering has a lifespan of approximately 30 days), as well as increased airflow.

PPE and Extra Measures

Apart from being an airborne virus, COVID-19 is also transmitted via touch, as it lives both on surfaces and on the skin. While it is generally advisable not to touch lift buttons or other touch-points directly, that, too, can damage the equipment when done excessively. A better alternative is washing and sanitising the hands regularly, which could be achieved by installing dispensers at the beginning of the boarding queue and right before entry in the lift car. Additionally, everyone riding the lift should wear masks and face coverings, and temperature checks should be provided to further reduce the risk of transmission.

Get more of Elevator World. Sign up for our free e-newsletter.