R&D at APEL, IIT-Bombay

by Sriram Rangarajan and Vivek Agarwal

Traction Elevator Drive, an Introduction

The biggest buzz around the world at present is the electrification of transportation. The moment we think of “Transportation Electrification,” the first thing that comes to mind is the electric vehicle (EV). While the common perception of EV is the electrification of road transportation vehicles such as bikes, auto-rickshaws, cars and buses, little do we realize that the elevator is also an EV utilized for the vertical transportation of passengers and goods. In fact, the basic working principle of elevator and conventional EVs is the same, as they both rely on the “Traction[1] Principle”: traction between the road and the wheel in case of conventional EVs and between the pulley (sheave) and the rope in case of elevators. In both cases, the ride comfort of the passengers depends on how smoothly the speed of the traction motor is controlled, and that’s where a power electronic converter plays a vital role.

The actual speed of the motor can be varied in a smooth manner if the magnitude and frequency of the fundamental component of the applied voltage can be varied smoothly. The power electronic converter provides such flexibility to condition the voltage applied to the motor in a desired manner by appropriately controlling the gate pulses given to the switches of the converter. The gate pulses are determined by the closed loop speed control algorithm that controls the actual speed of the motor.

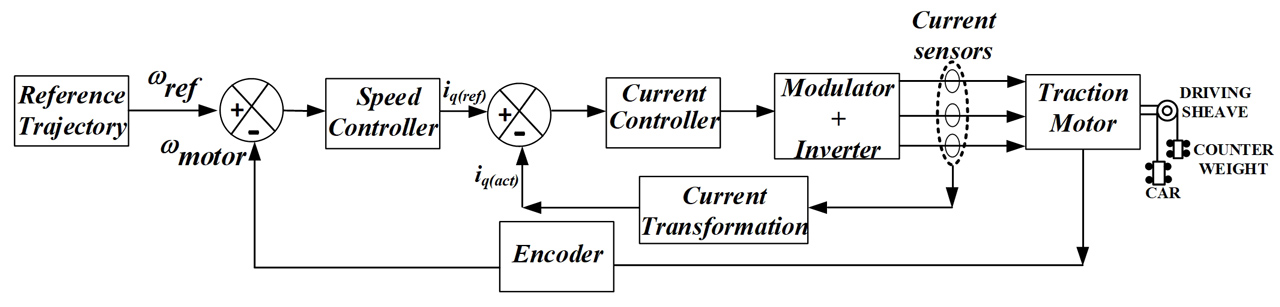

Due to the advent of high-performance processors/controllers and sensors, traction motors are nowadays controlled through sophisticated closed loop speed control schemes such as Field Oriented Control (FOC) and Direct Torque Control (DTC). This system, consisting of the traction motor, power electronic converter and the controller, along with the necessary feedback signals, is known as the “Traction Drive.” The control block diagram of FOC-based typical variable-voltage, variable-frequency (VVVF) elevator drive is shown in Figure 1. Since the drive varies the magnitude and frequency of the fundamental component of the voltage applied to the motor, these drives are commonly known as “VVVF Drives” in the market.

Over the years, significant R&D has taken place in the field of traction elevator drives, thanks to the R&D teams of leading elevator industries and academic research groups.

Past and Ongoing Research Activities at APEL, IIT-BOMBAY

Past Research Activities

Over the years, significant R&D has taken place in the field of traction elevator drives, thanks to the R&D teams of leading elevator industries and academic research groups. Various new converter topologies, new motor technologies, novel optimized reference trajectory generation techniques and novel position/speed control schemes have been developed. At Applied Power Electronic Laboratory (APEL) at the Indian Institute of Technology Bombay (IIT-Bombay), we have been working along the same lines in the field of traction elevator drives for over a decade and significant contributions have been made in terms of patents, publications in high-quality journals/conferences, consultancy projects and active participation in global expositions.

Our past research activities include the following:

- Loss-optimized trajectory generation for induction motor-driven geared elevator systems, which leads to low energy consumption compared to conventional trajectory generation techniques,

- Novel power electronic converter topologies to interface the super capacitor with the DC link of the elevator systems so that the regenerative energy could be trapped efficiently,

- Novel Power Factor Correction (PFC) topologies to minimize the Total Harmonic Distortion (THD) in traction elevator system.

Ongoing Research Activities

Active Damping for PMSM Driven Elevators

In recent times, the Permanent Magnet Synchronous Motor (PMSM) has become more popular than the induction motor for elevator systems. PMSM elevators are more compact, energy efficient and involve less maintenance. PMSM has made machine-room-less (MRL) elevators a reality and more than a mere thought. Nevertheless, the flipside is that they have some performance issues, such as increased probability of occurrence of low frequency longitudinal vibrations and instability under v/f control, to name a few. Our ongoing research activities are focusing on enhancing the performance of such systems. Due to the fact that PMSM elevators are gearless, their load-to-motor inertia ratio is quite high compared to that of the geared induction motor-driven elevators. Also, in order to reduce the torque rating of the motor, PMSM elevators incorporate higher roping ratios, which increases the number of pulleys in the system. The high load-to-motor inertia ratio demands a comparatively higher bandwidth speed controller, and the higher number of pulleys may increase the probability of pulley anomalies such as eccentricity, degradation, etc. Since there is a finite compliance (compliance of rope/belt, which acts as a spring) connecting the traction motor to the elevator car and counterweight, an elevator has multiple longitudinal vibrational frequencies, i.e., resonant and anti-resonant frequencies due to the spring-mass action. The higher bandwidth speed controllers for systems with high load-to-motor inertia ratio and eccentric pulleys/sheaves are always a concern, as they could provoke such longitudinal vibrations in the system. Sometimes, even small torque ripple of the motor may excite the resonances in the system. Also, the modern elevators are going for V-groove and undercut U-groove sheaves that could lead to faster degradation of ropes and sheaves, which may also excite vibrations.

Currently, we are working on addressing such vibration issues in gearless PMSM elevator systems. We are developing novel active damping techniques to mitigate the low frequency vertical/longitudinal vibrations in such systems. The term “Active Damping” implies that the damping is achieved without the presence of any passive damping elements in the elevator system. This is possible because the converter can be controlled to inject the current component responsible for generation of damping torque in the motor. To do this, we have worked extensively on modeling and controlling the complete elevator system. We are in active collaboration with NIDEC Motor Corp. (U.S.) and BRUGG Lifting (Switzerland) to validate the effectiveness of our modeling and proposed control schemes in their system.

Unlike induction motor-driven elevator systems, which can be operated with the v/f speed control technique, as well as with FOC/DTC, PMSM elevators have inherent stability issues if operated with v/f technique due to lack of damping.

The conventional methods of damping the low frequency longitudinal vibrations in elevators rely on either passive damping elements such as helical springs and resilient elastomeric material or on active/semi-active hitch control that demands an extra actuator, power source, sensor and controller. Our proposed active damping techniques can get rid of the aforementioned passive damping elements and do not demand any extra actuator and sensor. Since the proposed technique can provide variable damping, it can provide excellent ride comfort by damping the vibrations under any kind of disturbances explained previously. It must be pointed out here that, as the elevator system becomes more and more compact, components are becoming lighter and flexible; hence, high-performance vibration damping techniques are a must to maintain high standards of ride comfort.

v/f Technique for PMSM Driven Elevators

Another aspect of research on which we are focusing is reducing the tuning complexity of PMSM-driven elevator systems. Unlike induction motor-driven elevator systems, which can be operated with the v/f speed control technique, as well as with FOC/DTC, PMSM elevators have inherent stability issues if operated with v/f technique due to lack of damping. One of the major advantages with the v/f technique is that it involves fewer tuning parameters than FOC and, hence, simpler tuning algorithms could suffice for v/f technique. Even for low-rise elevators, PMSM demands FOC that could have otherwise been easily operated with the v/f technique in case of an induction motor. At present, sophisticated self-commissioning drives are available for PMSM elevators, which can determine the closed loop controller parameters (proportional and integral gains of the speed and current controller). We are researching novel v/f techniques for PMSM-driven elevators that could stabilize the system and maintain ride comfort within the prescribed ISO 18738 standards. We believe that, with this technique, the number of tuning parameters could be brought down to one-third compared to that of FOC-based, PMSM-driven elevators. This increases reliability, offers simplicity in tuning and brings down commissioning time.

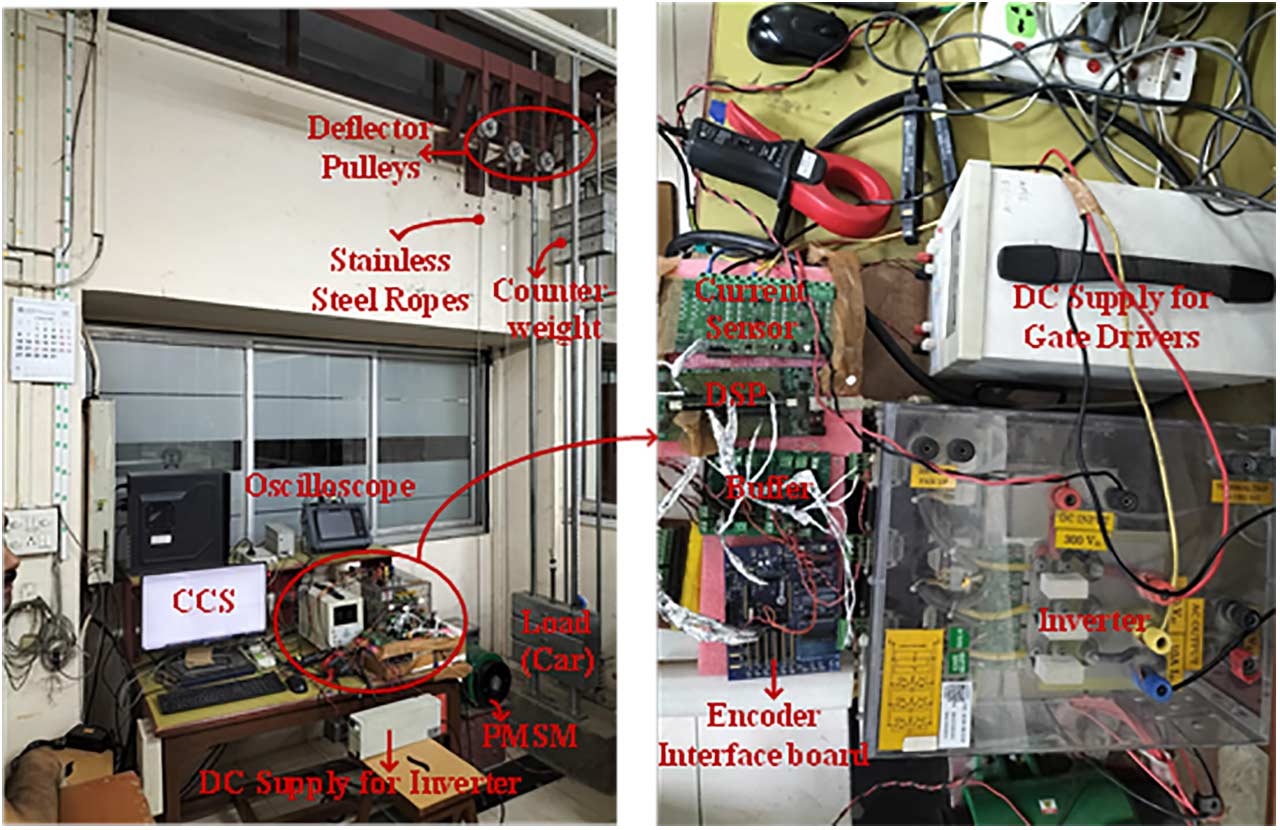

To validate our research, we have developed a laboratory prototype of a PMSM driven elevator system at APEL, IIT-B as shown in Figure 2. The current sensing, buffer circuits for gate driver and Sin/Cos encoder interface card, closed-loop controller algorithms in DSP and the mechanical set up to vary the carload (from 0 kg to 150 kg) and counterweight (from 0 kg to 75 kg) are indigenously developed. PMSM is procured from Bharat Bijlee Ltd., Mumbai. The Sin/Cos encoder interface card is procured from iC-Haus, Germany. The developed prototype is bottom driven and has been designed to study both longitudinal and transversal rope vibrations.

References

[1] Traction relies on the friction between two surfaces.

[2] Control loop of only the current component responsible for torque generation is shown here.

Get more of Elevator World. Sign up for our free e-newsletter.