Trust, Value and Communication

May 1, 2024

This Readers’ Platform spotlights three family-run companies.

In North America, most installation, repair, service and inspection of elevators, escalators, moving walks and other conveyance equipment is done by elevator constructors employed by large, multinational corporations. With a presence in every state in the U.S. and every province in Canada, companies such as Otis, Schindler, KONE, TK Elevator, Mitsubishi Electric and Fujitec give building owners and managers access to a broad, diverse workforce of trained, highly skilled elevator constructors to meet the needs of their projects. But, big companies may not be a good fit for every job or every situation. For people who own or manage buildings within a smaller geographic radius, it may be preferable to work with companies where a trouble call or request for specialized work is answered directly by the people running the company.

ElevatorInfo, a news and information hub developed by the Elevator Industry Work Preservation Fund (EIWPF), recently spoke with representatives of such companies — small, family-run companies that are signatories of the International Union of Elevator Constructors (IUEC). They told us about what they believe sets them apart. Three of their stories are below.

TriStar Elevator

Brandon Jackson, vice president of TriStar Elevator, headquartered in the Nashville, Tennessee, suburb of Columbia, said:

“(With) a company like TriStar, which is an independent, you get specialized care. I feel we do better with our goals in customer service. We answer the phone; we respond to emails. This is a service-based company, a service-based trade. When we can take that elevator off of that property manager’s mind, they can worry about the rest of their building. When we can take that elevator installation off of the project manager’s mind, we’ve done our job.”

TriStar’s crew of 14 elevator constructors installs and services residential and commercial elevators, escalators and other conveyance systems in Greater Nashville and across the middle-Tennessee area. While Jackson started his career as an elevator constructor years ago, the decision to launch a new elevator company as a family business with his wife, Stacey (the company’s owner), was fairly recent. “We started this four years ago,” she said. “It’s very hard, but it’s very rewarding as well.”

Customers are not the only ones who benefit from the personalized connection TriStar upholds — the connection also extends to its employees. “We look at each one of our employees like they’re a family member,” Jackson said, continuing:

“When we hire somebody, we want them to succeed. Being able to provide that kind of workplace for them, that’s important to me, knowing that every day they’ve got a company that wants them to work safely and go home safe. And we have the resources to make that happen.”

Because TriStar is a signatory company of the IUEC, its apprentices and mechanics complete a U.S. Department of Labor registered apprenticeship through the National Elevator Industry Educational Program (NEIEP) — the same training program as the technicians employed by the major signatory OEMs. In fact, many of the elevator technicians TriStar employs began their careers at one of the industry’s large companies. They said they made the switch to an independent because of the positive workplace culture such companies provide.

“Working for TriStar — and just in Nashville — is wonderful,” said TriStar mechanic Michael Halfacre. When ElevatorInfo asked him why, he said it is because of TriStar’s family-oriented culture, responsiveness and focus on jobsite safety. “If you have to call somebody, they answer,” Halfacre stated. “TriStar ensures we have a safe jobsite by giving us everything we need to make it safe.”

Evolution Elevator

Similar to the mindset at TriStar, Lou James, managing partner and co-owner of Evolution Elevator & Escalator Corp., along with his wife, Carla (the company’s primary owner); brother, Chris; sister-in-law, Rosemarie; and brother, Thomas, said that being a family business makes for stronger connections and better communication within the company and with customers. Evolution installs, repairs, services and maintains conveyances in some of the biggest and busiest metropolitan areas in the U.S.: NYC, Miami and the surrounding areas. “We service everything — escalators, moving walks, elevators, dumbwaiters, handicap lifts, you know, soup to nuts,” James said. “If it’s in vertical transportation (VT), we take care of it.”

James is a firm believer that communication among all members of his team is key to the company’s success. “Communication’s at the forefront,” he said, emphasizing that it is also vital to working safe, adding:

“We have a number of procedures that we follow. We communicate with each other, not just the office talking to the techs, but the techs talking back to the office, the techs talking to each other. That’s really, really important because this is going to be the difference between a possible injury to us or the riding public, or the key to getting ahead of a potential problem.”

An emphasis on collaboration is also a core value of the company. This is put into practice at Evolution, as it doesn’t separate the management of the company from the work it does in the field. As an IUEC member who brought with him his experience as a career elevator mechanic, James regularly swaps out his management hat for a hard hat and jumps in to work on equipment when necessary. He’s still on the rotation for late-night trouble or entrapment calls.

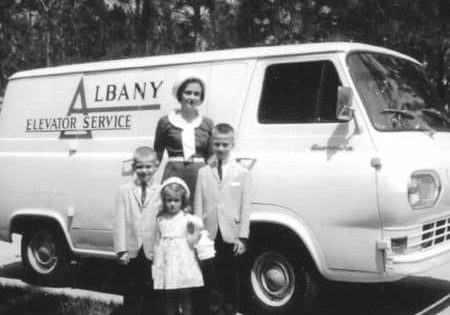

Quality Elevator Co.

Quality Elevator Co. Inc. is another example of a thriving family-run elevator business. Under the leadership of Jim Snider, executive vice president (EVP), Quality has grown to become one of the largest independent elevator service contractors in the Maryland, Virginia and District of Columbia region. For Snider, joining the elevator industry was a family tradition. After graduating from high school and beginning training as an electrician, he became an IUEC Local 10 elevator installer at a small company that was eventually acquired by Schindler. In the mid-1980s, Snider passed the NEIEP Mechanic Exam and transferred to Quality Elevator, a local/regional independent company that had been started by his father, Gene Snider, and another local elevator constructor, Jack Higgs. Jim Snider spent most of his career as a field mechanic before transitioning to a management leadership position.

Because he came from an elevator family and spent many years turning wrenches in the field, Jim Snider has firsthand knowledge of what it takes to become a good elevator mechanic. During our interview, he emphasized the importance of “going above and beyond,” explaining that ensuring the workforce is properly trained is one of the smartest investments a company can make. “We invest heavily in training, and the union really helps us out with that,” he said. “They have an excellent educational program.”

ElevatorInfo connected with Jim Snider again at the annual 2024 Elevator Contractors of America (ECA) conference, a gathering where independent elevator companies from across the U.S. come together to learn and share information and experiences. ECA’s mission is “to foster and promote the elevator industry by obtaining uniformity, harmony and certainty in the relationships between employers and employees.” During a question-and-answer session toward the end of ECA’s final day, one of the presenters asked the group why building owners and managers would want to hire an independent company over a large corporation with an international presence. The answer? Trust, value and communication. As exemplified by the work of the three elevator companies profiled in this article — TriStar in greater Nashville; Evolution in the New York, New Jersey and Miami areas; and Quality in the region surrounding Washington, D.C. — it became evident that family-run businesses are the perfect fit for customers who seek personalized service and connection.

About ElevatorInfo

Get more of Elevator World. Sign up for our free e-newsletter.