U.S. Senate Handicap Accessibility Lifts

Jan 6, 2023

Custom lift specialist fine-tunes an innovative system serving top lawmakers.

Platform Lifts & Stairway Chairlifts – Washington, D.C.

submitted by John C. Linsley,

Gillespie Corp.

Introduction

Twelve years ago, Gillespie Corp. designed and built two handicap accessibility lifts for the U.S. House of Representatives Speaker’s rostrum in the U.S. Capitol in Washington, D.C. This lift system won ELEVATOR WORLD’S 2011 Project of the Year in its category and has been in operation, when needed, ever since.

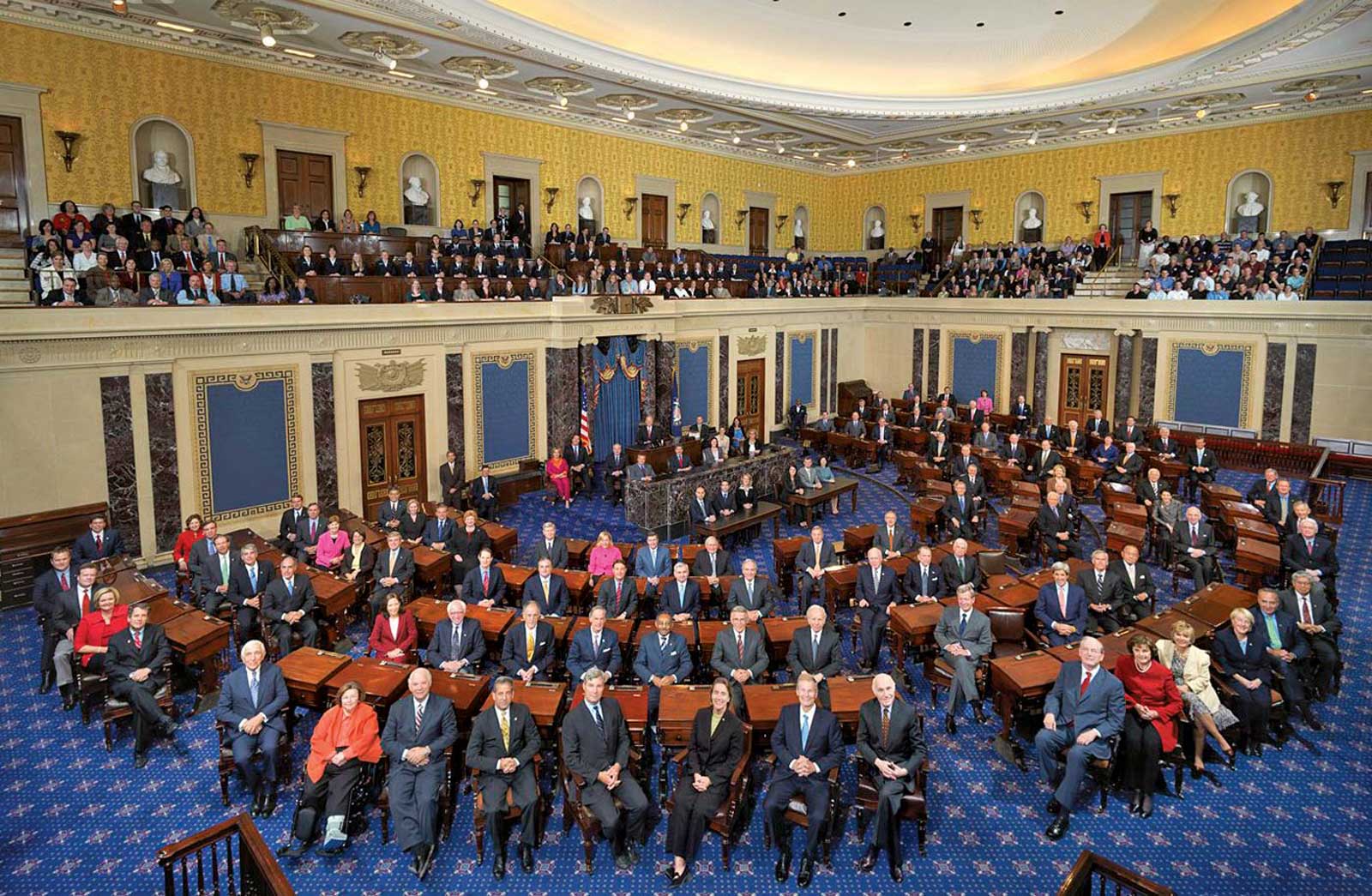

In August 2020, Gillespie was once again approached by representatives of the U.S. Capitol to design hidden handicap accessibility lifts for the U.S. Senate chamber to provide access to the vice president’s chair. This seat is normally occupied by the president pro tempore, but is occupied by the vice president when a tied vote needs to be broken or during special occasions. The physical layout of the Senate rostrum — the location from which the speaker of the house presides — is completely different from the speaker’s rostrum of the U.S. House of Representatives, so a different solution was in order.

The Challenge

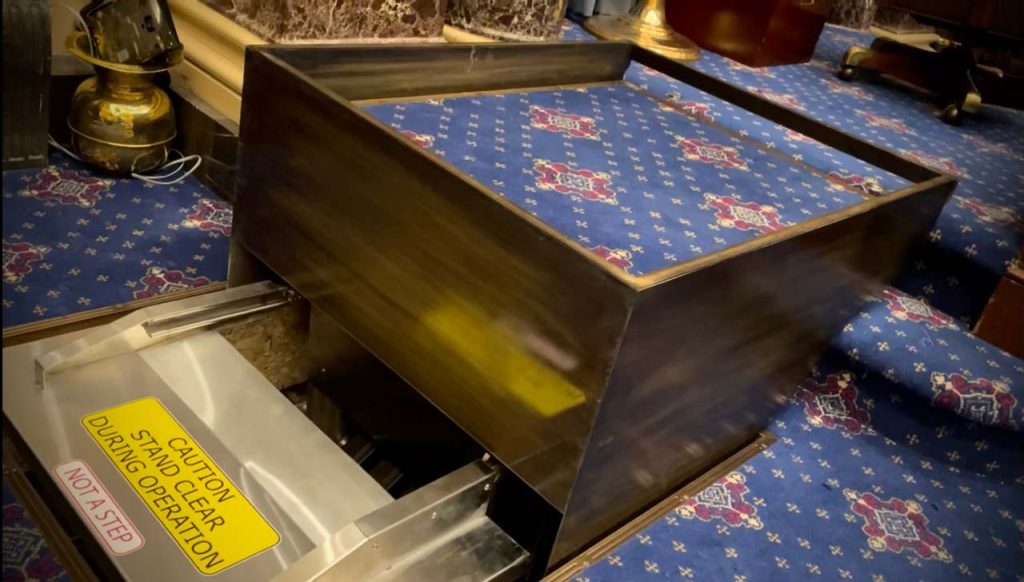

The challenge was to design two identical lifts to bring a handicapped individual from the Senate floor up to the midlevel, and again from the mid-level up to the upper level where the vice president’s desk is located. Each rise is two steps with landings in between. Normally, the lifts will be parked at their lower landings so they may be walked over with no issues. All finish work was to be carpeting and antiqued bronze. The lifts were to be attendant-operated and have constant pressure operation. When the lifts are parked at the lower position, they were to be as inconspicuous as possible. When the lifts are in the raised position, it is important the exposed areas be protected in some manner. Before any movement of the platform, it is necessary to raise curbing to prevent a wheelchair from being able to roll off. The front curb needs to be able to raise and lower independently when the lift is at the upper landing for egress and access to and from the upper landing.

Unlike the House of Representatives lifts (which were raised and lowered with a scissor mechanism and subsequently used an extendable platform section to access the upper landing), the Senate lifts were designed using curvilinear motion.

The Solution

Gillespie’s Engineering Manager John Linsley assigned this difficult job to Senior Design Engineer Yakov Mikhlin, who proceeded to model the lifts in three dimensions. Unlike the House of Representatives lifts (which were raised and lowered with a scissor mechanism and subsequently used an extendable platform section to access the upper landing), the Senate lifts were designed using curvilinear motion. This type of motion is the result of two pairs of parallel arms attached to the platform and pivoting from the lower frame, resulting in the platform itself resembling an arc as it travels up and forward, all while staying parallel with the floor at all times.

The tricky part regarding this type of motion is that geometry is all-important, as the platform is always going both up and down as well as backward and forward. It is not an easy matter to have the platform Stop the proper distance from the upper landing while also at the correct height. Change one parameter (for instance the length of the parallel arms), and one will have changed the relationship between vertical and horizontal travel.

Design and Production

Under the direction of Operations Manager Greg Thompson, Gillespie then proceeded to fine-tune the design and order all components including the controllers, actuators, bearings and materials. Both lifts were built together, although they were assembled and adjusted separately.

Gillespie found an electric actuator manufacturer that produced actuators it advertised as being synchronized. We selected three actuators to achieve the force necessary to lift the loaded platform. Plugged together, they were supposed to act as one. This did not turn out to be the case. As with all custom work, something is bound to cause problems. What was happening with the actuators was that, as you ran the lift up and down, the actuators would accumulate small differences in stroke, eventually causing one actuator to attempt to perform all the work by itself. This would thereby cause an overload failure. If they were truly synchronized, this would not have occurred.

To solve this, we adjusted the lifts so that when they were at the lower landing, the actuators would be fully retracted. This would resynchronize the actuators mechanically. They would then remain close enough in stroke during raising and lowering of the platform to avoid an overload. In addition, we installed small stacks of wave spring washers at the ends of the pistons to allow for small changes in length during travel. This turned out to work just fine. We used smaller actuators to raise and lower the side/rear curbing and the front curb independently. These actuators did not cause any issues.

Though the actuators themselves had internal limit switches, we implemented additional position switches at both travel terminuses to let the controller know the platform was fully raised or fully retracted. This was to allow raising and lowering of the curbs. The chosen switches did not have enough travel distance. As people walked over the lift when parked at the lower landing, the lower position switch would be nudged out of position. When this happened, the lift could not be used, as the curbs were prevented from raising. Only when all the curbs were raised could the lift start moving. After selecting and installing more suitable switches that had more movement and were more forgiving, this vexing problem disappeared.

Operation

To operate either platform lift, an authorized person standing within feet of the lifts turns on the units with an on/off key at the control station. Identical controls were located on either side of the on/off key, and were simply up/down constant pressure buttons and an in-use light labeled for Lift A or Lift B. Starting at the lower lift in the lower position, the lift passenger positions themself onto the platform. The attendant then pushes the “up” button, which causes the curbing to rise into position. Once the curbs are in the raised position, the platform begins to move upward and forward toward the upper step, eventually coming to a stop even and level with the upper landing. Continuing to hold the “up” button causes the front curb to retract, allowing a wheelchair to be moved out onto the landing. The lower lift could then be left in place or lowered to the lower landing and parked.

Operation of the upper lift is identical. To move the passenger to the lowermost landing on the Senate floor, the passenger, once again, gets onto the upper lift and the attendant then pushes the “down” button. The front curb raises up and the platform moves downward to the lower position. Once level with the lower landing, all curbs retract so the wheelchair can then move onto the lower lift, which then repeats this action. When complete, both lifts are parked at their lower landings and all curbs are retracted flush with the floor.

Conclusion

Gillespie builds unique elevators, lifts and cranes. We undertake the jobs that fall outside of the purview of other companies in the industry. These handicap accessibility lifts were designed and built to last for many years. Currently, U.S. Senator Tammy Duckworth is using these lifts every Monday afternoon as she performs the duties of president pro tempore. Once again, Gillespie has demonstrated its ability to face a difficult challenge and arrive at a practical solution through imagination, engineering and manufacturing capability.

Credits

Client: U.S. Capitol Building, U.S. Senate Chamber

Design and Manufacturing: Gillespie Corp., Ware, Massachusetts

Installer: U.S. Capitol Building, Architect of the Capitol, Operations Manager Greg Thompson

Engineering Team: Yakov Mikhlin, Demetri Kachulis and John C. Linsley

Fabricating Team: Pawel Bzdula, Roger Jerome, Leszek Lebida, Steve Salerno Sr. and Donald Boos

Controller Manufacturer: Virginia Controls, LLC

Metal Fabricating Vendor: Kad Industries, Chicopee, Massachusetts

Fixture Manufacturer: C.J. Anderson & Co., Harwood Heights, Illinois

Get more of Elevator World. Sign up for our free e-newsletter.