Ultrasonic Alarm System for Monitoring Distance between Elevator Counterweight and Buffers in Real Time

Aug 1, 2013

by by Ning Li, Yihui Ruan, JieFeng Li and Bin

Elevator maintenance personnel often have to climb to the top of an elevator to repair or maintain it. In order to ensure safety, EN 81-1:1998 and GB 7588-2003 have established various stipulations. When the counterweight rests on its fully compressed buffer(s), the following conditions shall be satisfied simultaneously: the car guide rail lengths shall accommodate further guided travel, expressed in meters, of at least 0.1 + 0.035 v2. The free vertical distance between the level of the highest area on the car roof, the dimensions of which comply with 8.13.2 (areas on parts according to 5.7.1.1), and the level of the lowest part of the well ceiling (including beams and components located under the ceiling) situated in the projection of the car, expressed in meters, shall be at least 1.0 + 0.035 v2. The free vertical distance, expressed in meters between the lowest parts of the well ceiling and the highest pieces of equipment fixed on the roof of the car enclosure below, shall be at least 0.3 + 0.035 v2. The highest part of the guide shoes or rollers of the rope attachments and of the header or parts of vertically sliding doors, if any, shall be at least 0.1 + 0.035 v2.

Final limit switches shall operate before the car comes into contact with the buffers. The action of the final limit switches shall be maintained while the buffers are compressed. There shall be appropriate space of the car top when the counterweight compresses its buffer(s) completely. This also leads to limited vertical distance between the elevator counterweight and buffer(s). The value seems to be permanent after the first inspection, while wire rope is essentially an elastic member, stretching or elongating when under load. It will change with the running of an elevator after a period of time, particularly for elevators in high-rise buildings. If the value is too high or low, it can be difficult for the space of the car top to meet the aforementioned requirements and to ensure the safety of elevator maintenance personnel.

This article introduces a new method to comply with the stipulations and to monitor distance between the elevator counterweight and buffer(s) in real time. Users only enter the permissible upper- and lower-limit values of the distance, which can be calculated in advance. Once the actual distance value on site exceeds the calculated value, the host in the elevator pit can send alarm messages set in advance to communicate with the host to mobile phones, prompting elevator maintenance personnel to go to the jobsite to adjust the elevator. The device, which uses microcontroller and sensory technology, has several application prospects.

Scope of Distance between Elevator Counterweight and Buffer(s)

Figure 1 shows four vertical distances on top of an elevator car. The distance between the elevator counterweight and buffer(s) shall have a maximum and minimum permissible value according to the aforementioned analysis.

For a detailed analysis of the distance, suppose H1 is 0.1 + 0.035 v2, H2 is 0.1 + 0.035 v2, H3 is 0.3 + 0.035 v2 and H4 is 1 + 0.035 v2, all of which are expressed in meters. When the elevator car is level with the floor of the highest landing, four values can be measured and labeled L1, L2, L3 and L4. The stroke distance of the fully compressed buffer(s) is h0. Figure 1 provides a view of an elevator’s complete structure. The calculated minimum value is Min(△i), and Min(△i) = L1 – H1 – h0,andi =1, 2, 3, 4.

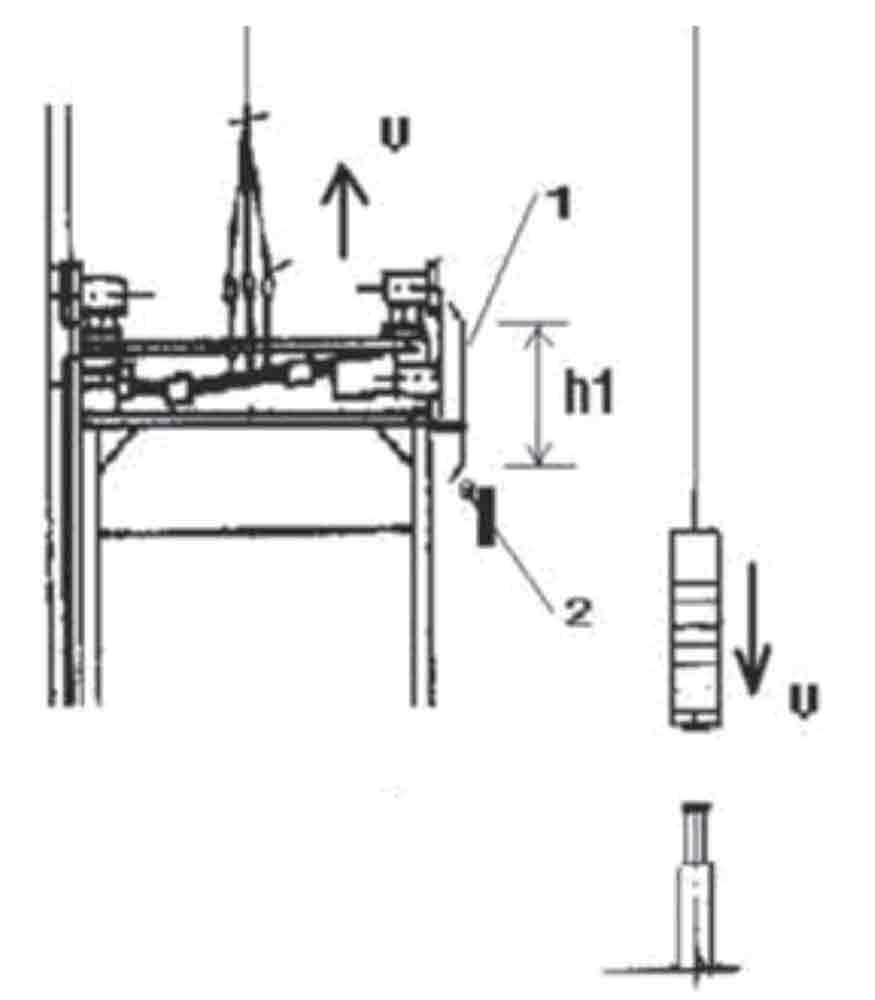

The final limit switch will be activated by the limit strike bow when an elevator runs upward. At this time, the vertical distance between the hoistway top sill and car sill can be measured and called h2. Suppose the vertical length of the limit strike bow is h1, and M = h2 + h1 – h0. The maximum permissible distance between the counterweight and buffer(s) is the smaller value in both M and Min(△i).

When the final limit switch is activated by the limit strike bow, the distance between the counterweight and buffer(s) shall be less than the distance between the final limit switch and limit strike bow, so the distance value will have a minimum permissible value h2. Figure 2 illustrates an elevator’s limit strike bow.

In an extreme case, a limit strike bow is attached to an elevator car, and the bow’s length (h3) is slightly longer than the height of the car. There is a gap between the hoistway top sill and car guard when an elevator car runs upward and overtakes the highest floor. This can make rescue operations dangerous in the case of entrapments. If the height of an elevator car guard is h3, the distance between the counterweight and buffer(s) shall be less than h3 – h0. In summary, the smallest of M, Min(△i) and h3 – h0 is the maximum permissible value between counterweight and buffer(s).

Monitoring System

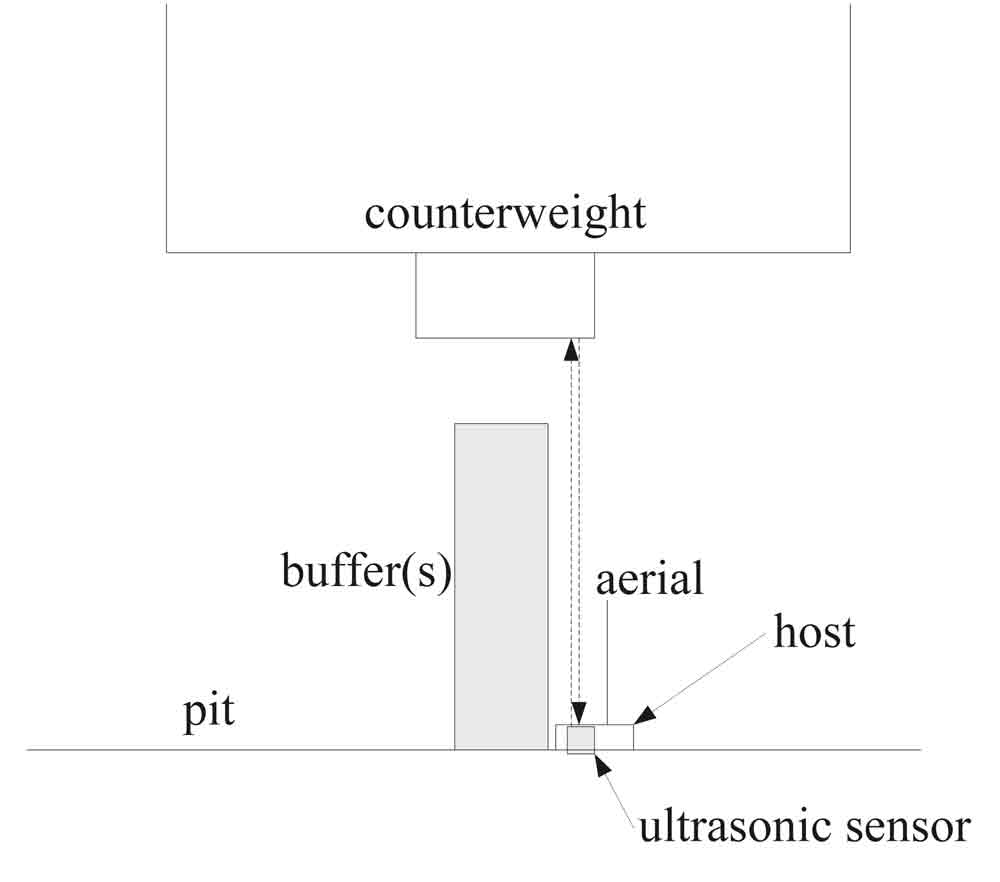

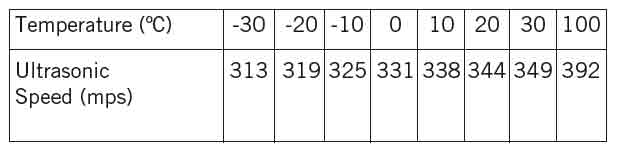

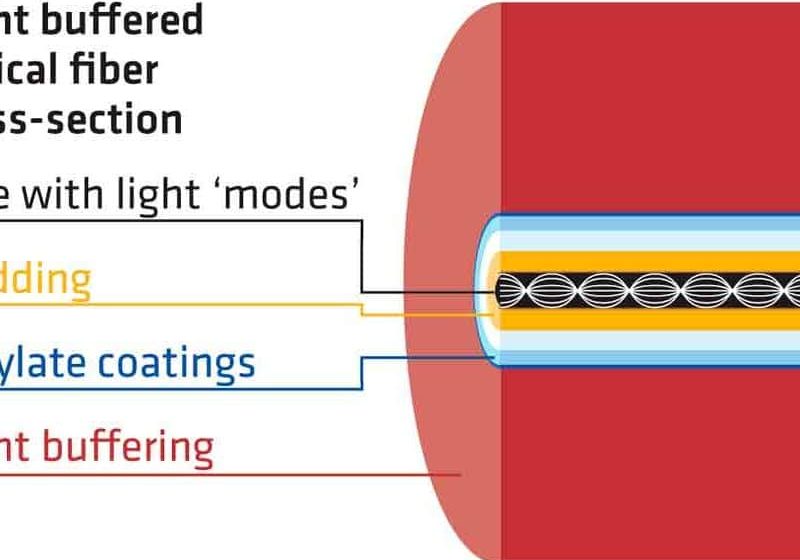

The host of this monitoring device should be put in its proper place (Figure 3). The selected ultrasonic sensor combines an ultrasonic transmitter with an ultrasonic receiver. The transmitter sends its signal through the air to the receiver. This travel time is t. The ultrasonic speed v is a fixed value at a certain environmental temperature. The relationship between temperature and ultrasonic speed can be seen in Table 1. The traveling distance is L, and L = vt.

The ultrasonic speed will change depending on environmental temperature, so a temperature sensor is used to obtain the ultrasonic speed by means of temperature compensating. The distance between the counterweight and host is L/2. The height of the buffer(s) is h. The distance between the elevator counterweight and buffer(s) is S, and S = L/2 – h.

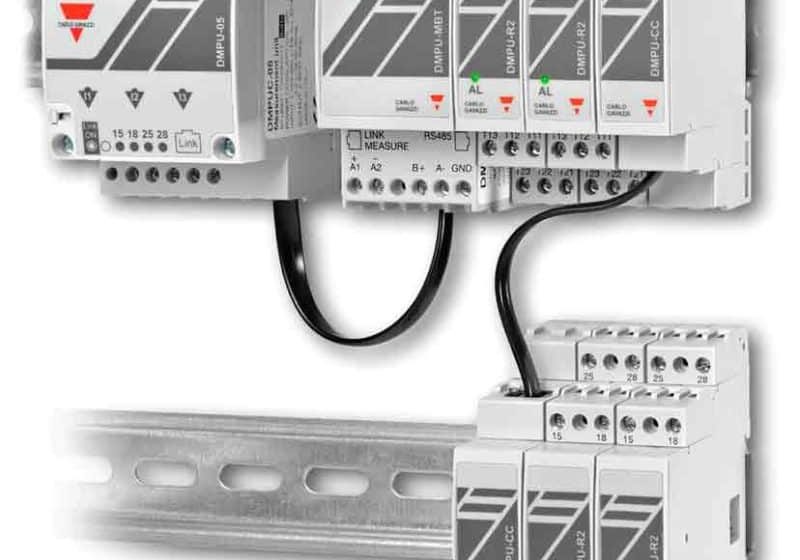

Figure 4 illustrates the hardware composition of this instrument, which is comprised of an ultrasonic sensor, a temperature sensor, a global system for mobile communication (GSM), a microcontroller, a display screen, a subscriber-identity-module card, mobile phones, etc. The microcontroller can receive signals from the ultrasonic and temperature sensors. After calculating and analyzing the data, the microcontroller sends alarm signals to mobile phones through GSM.

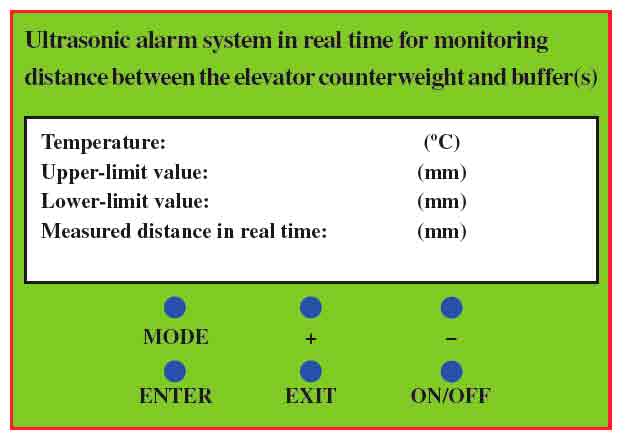

Figure 5 shows the front panel of the host. The microcontroller system and large chromatic liquid-crystal display make the operation more convenient and provide a user-friendly interface. When turning on the host, pressing and releasing the “MODE” button will cause switching between the upper and lower limit values. Pressing “+” or “-” will increase or decrease the initial value by one. Pressing and releasing the “ENTER” button will confirm the current value, and “EXIT” is used to exit the current mode. Pressing “ON/OFF” will turn the host on or off.

Conclusion

As elevator technology develops, more and more industry professionals are focusing on elevator safety. Wireless communication and electronic-information technologies will play a more important role in the improvement of elevator safety in the future. The system discussed in the article enables elevator personnel to monitor the distance between the counterweight and buffer(s) in real time, which is useful to elevator safety.

Get more of Elevator World. Sign up for our free e-newsletter.