Understanding Problems of Suspension Means

Jul 1, 2019

In this Readers Platform, an industry veteran shares ideas for addressing an industrywide challenge.

Over the last two decades, big money has been spent on elevator rope replacement, but half or more of that spending could have been delayed. New tools and software can help identify and manage issues of excessive and uneven wear of sheave grooves, as well as early failure of elevator suspension means. There are remedies/adjustments that will extend service of already compromised ropes/sheaves.

It’s hard for me to believe now, but a little more than 16 years ago, I was just starting out as a general manager of an elevator rope manufacturer. They were challenging times: times that demanded I pick up whatever I could from literature, conversations with experts and from what I saw onsite. I was quickly introduced to the vast array of problems that confront wire ropes in elevators every day. Since then, I’ve learned even more, and have begun to figure out how to break down various complicated issues into simple terms and concrete, directed actions. Here, I’m trying to avoid repeating technical writing on wire ropes that has already appeared in the pages of ELEVATOR WORLD.

MRL designs present a special challenge when it comes to observing the rope at the drive machine.

For my commentary to reach the widest number of readers, it’s best to focus on just three main areas of discussion. First, the most important thing when installing elevator ropes (described below); second, the universally accepted fact that differential loading (usually thought of as equalization) of ropes (or other suspension means) is critical; and third, that the design and/or the present condition of the elevator installation profoundly impacts the fatigue, wear and failure progression of elevator ropes. This last point is important and a big issue, because combining variables exacts a huge impact on rope performance and drive sheaves.

The Main Thing When Installing Elevator Ropes

My apologies to friends and the many people I have met who install elevator ropes: this first, important point is not intended to be critical of you. Most everyone has heard about the great competitive pressure to install elevators fast, then do the same with maintenance processes. That’s business.

For round elevator ropes, their designed and manufactured structure must be preserved during handling and installation. Nearly all rope manufacturers understand this and have added a production/closing orientation line (many colors are possible, but white and yellow are currently common) longitudinally painted along the length of the rope. Over the past decade or so, many more demanding elevator installations are utilizing 2:1 roping, double wraps, some interesting diverter sheaves (like underslung arrangements), along with smaller drive sheaves and aggressive sheave/groove profiles. There have been complete articles written about these installations.

Pulling ropes into installations like these is very demanding for the ropes and very demanding (and disorienting) on the people installing them. The difficulty of the process almost guarantees that many installations are not good — not good at all with respect to orientation of each rope before the ends are shackled (fixed at both ends). Failing to keep track of the painted line during installation on just one rope out of a set simply means that that rope will be the defining factor of that rope installation.

The impact on rope life (fatigue to estimated failure) is big. Reducing rope life by 50-75% is in line with testing and estimations on this issue. For a system with calculated rope life of only about five years (also not unusual these days), a 75% reduction in expected rope life suggests a short life of one year, three months. We are seeing this kind of result many times in many places and know others in the industry are seeing it, too.

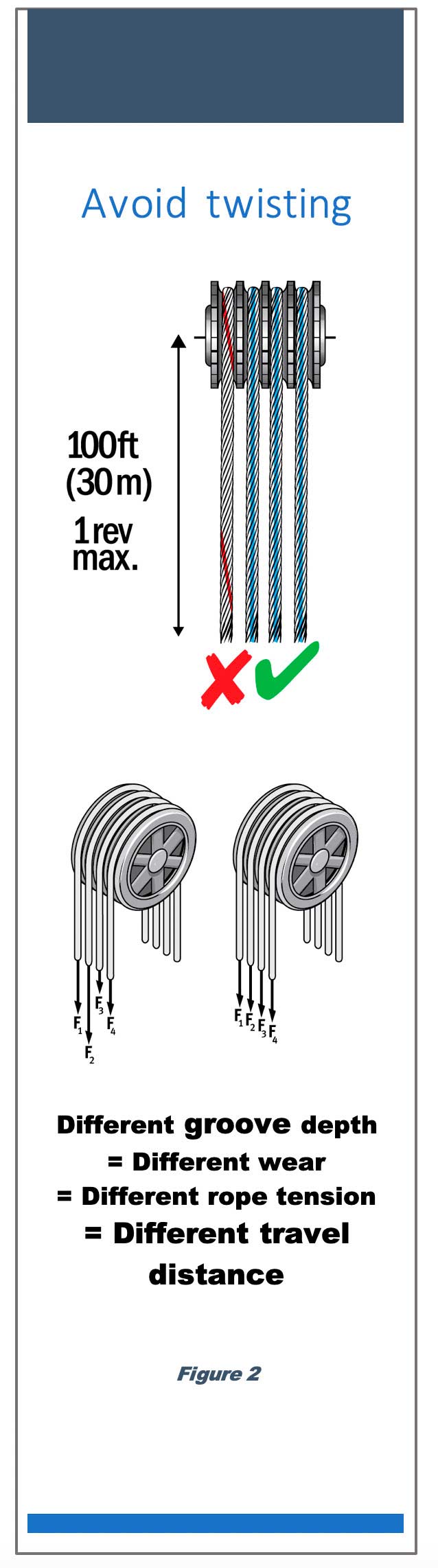

When an elevator rope is twisted out of its manufactured state (designed intent), fixed at both ends, and the elevator runs between the two fixed ends, that rope is quickly and irrevocably compromised. A simple diagnostic test can check for installation-induced rope torsion. Go to the drive machine and watch the ropes as the car is driven from the bottom floor to the top floor, then again from the top floor to the bottom floor. The rope installed must have been originally manufactured with a painted or sprayed line on it.

Observe the line as the elevator travels. A good way to do this is to take a video. Depending on the design/construction of your rope, there should be no more than one to three turns of the rope for about every 100 ft. of rope travel. Every installed rope needs to be checked. If you can see more turns than this, you have a little work to do. This task is not especially easy, but it can and needs to be done.

You must turn the shackle of each rope that is twisted in the opposite direction of the twist. Do the best you can to neutralize the twist. If you don’t, it is guaranteed that you will be back sooner — rather than later — to replace a set of ropes. Machine-room- less (MRL) systems present a special challenge when it comes to observing the rope at the drive machine. You might have to rig up a camera (consider a GoPro) so you can look for any twisting remotely.

Final words on this: don’t buy elevator ropes that don’t have a painted line on them. Make sure the rope orientation is controlled during installation using that line, and that that line is used for a final check and adjustment as soon as possible after installation. If the installing team or service team following does not do this almost immediately, the reference line on the rope can be rubbed, smeared and worn away. Then, there is no way to see and correct this problem. A set of ropes and the drive sheave will likely be irreparably damaged.

Correcting this failure alone offers a very big savings opportunity for our industry. It’s time for installation and service companies to take advantage of this relatively easy opportunity. Also, it’s time to stop thinking that your elevator rope manufacturer is the source of your problem. Basically, they all offer similar designs, and they all put ropes together in pretty much the same way.

The elevator industry has wasted a lot of time and money pursuing the false notion that the big problems with elevator rope are necessarily rope related.

The elevator industry has wasted a lot of time and money pursuing the false notion that the big problems with elevator rope are necessarily rope related. Some of the thinking has been that ropes are just not manufactured as well as they used to be; that maybe they are failing because recycled or lower-grade steel has been used in the wires or that maybe we are not properly lubricating elevator ropes.

Sorry, but all these ideas are wrong. The issue of torsional twist at installation is the overriding failure. The remaining two items to be discussed in this column will point the way for dealing with elevator installations as they are designed and/or also to the state they are in (after problems with the installation create other problems).

“Balanced” Loading of Ropes

This has been talked about for years. Based on what we knew until now, it has been called equalization. I have not found anyone who does not think this issue is important for ropes. Again, the challenge has been the problem of time to handle the task, wrapped up with the fact that practically every equalization method used in the field was not only difficult to do, but each offered only inadequate chances for success.

Again, with today’s elevators incorporating 2:1, double-wrap, underslung and smaller diameter drive sheaves with aggressive grooves, you cannot set and try to equalize (balance) ropes with just your hands (pulling and subjectively judging). Even trying to adjust tensions with a single tool (like a fish scale or a rigged-up torque wrench) is now clearly a fool’s errand. The problem with adjusting one rope at a time is that, while you are doing that, you are also impacting the load on the other ropes. Your impact is unknown. You go to the next rope, adjust it, and the same thing happens. It’s a circular process; a big waste of valuable time. Tool systems that solve this problem have been available for years.

In my early years of having to respond to early rope failure problems, I realized that effective tools were needed but were not available at the time. Making adjustments on individual ropes with something like a tensioning scale may have worked in the past, when elevator systems were less demanding and more forgiving. I have come across people who still believe strongly that they can adjust ropes effectively this way. You cannot. It’s likely that you never really could, but we got away with it then, because systems were very forgiving. I am completely convinced about this. Keep reading.

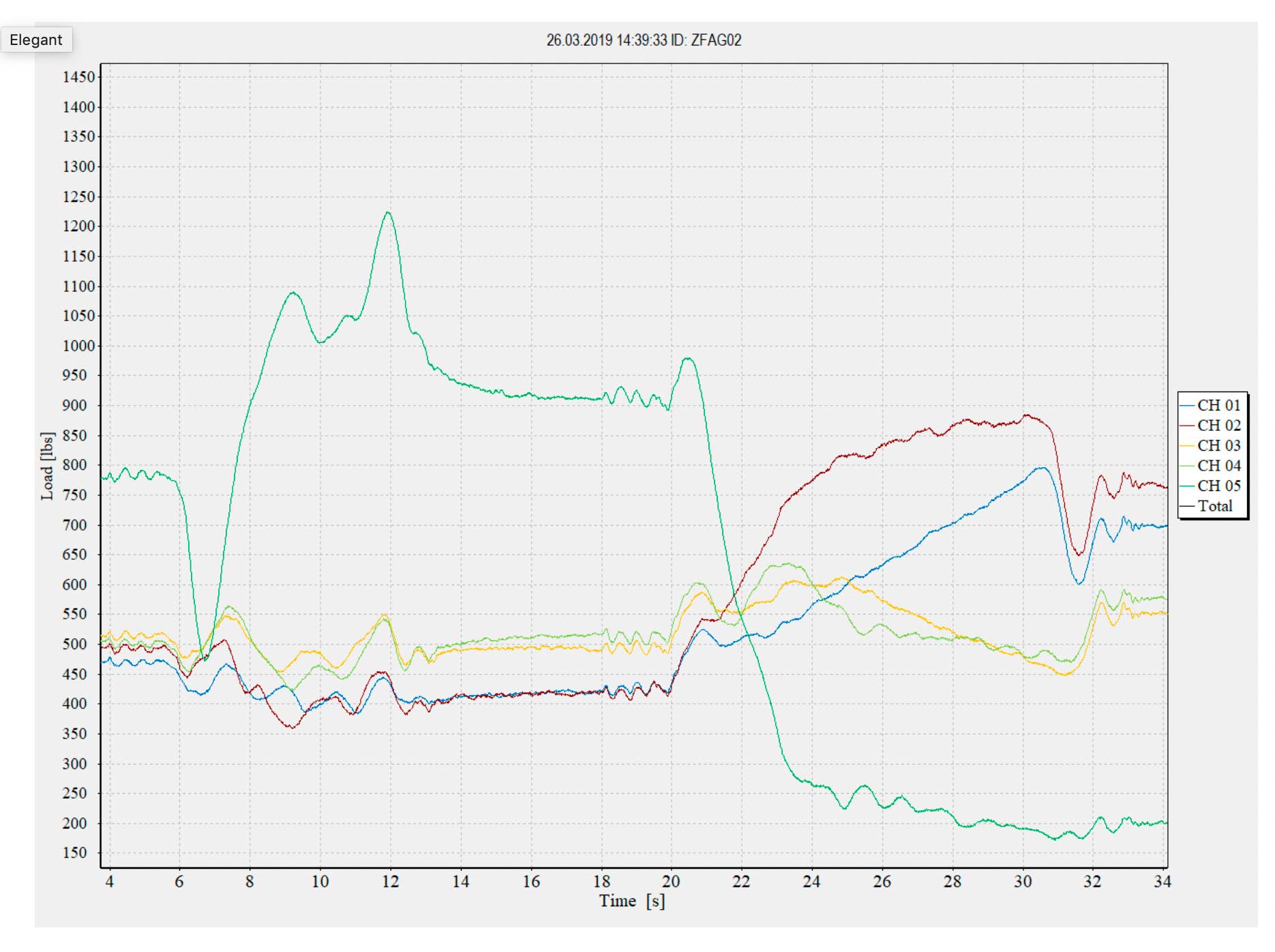

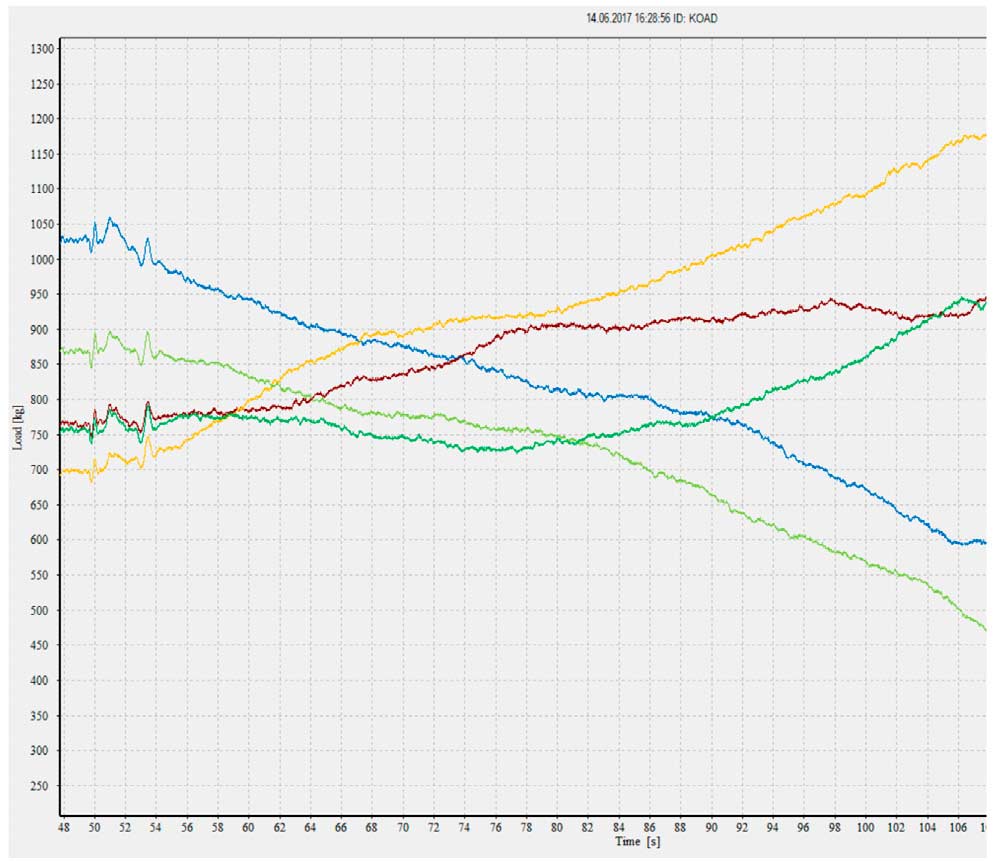

We started to develop our skills using tool systems for which one can actually see the complete and relative effects of loads on ropes. We really knew nothing about the fact that the loads on individual ropes change dramatically as the elevator runs up and down. Those who took the time began to note that whenever “equalization” adjustments were made on ropes, measuring them again could yield completely different results. It didn’t matter if you took your measurement in the same place (measuring in exactly the same location on the rope is impossible, and is confounded by the physics of steel and wires), you will get different values every time you measure. And, the different values are even more dramatic when you choose to take measurements at another place in the hoistway. This could lead to a long explanation with details about several aspects as to why; however, I will keep it brief.

Simply put, the load on individual ropes (or belts) changes dynamically. This is due to the angles created by fixed hitch points and the suspension means with its load as it comes closer to the drive sheave at a set fixed point. While the degree of the angles remains the same, as the elevator car approaches the extremes, both car/counterweight (CWT) loads increase and decrease dramatically relative to each other. In addition, those loads increase with small twists or turns as the load comes close to the hitch point. This is the key factor in this dynamic.

There is also the added effect of compensation systems (whether or not there is one — both impact relative and positional loading in different ways, but they are impacting it nevertheless). We also need to consider that any attempt to perform an equalization of the ropes may not have been done; was poorly done; or, possibly, done completely wrong.

Then, there are also the effects of a system that has worn sheave grooves (or bearings, or reduced diameter ropes because they are worn). This changes the dynamics of relative loading on the suspension means themselves. It is complicated and dynamic.

For years, we really had no idea what we were up against. Writing this, I can understand why there would be a lot of misunderstanding and frustration concerning equalization. I lived through a time when just the rope was blamed and every manufacturer, at one point or another, was blamed. For a while, each had to suffer as the scapegoat.

You can understand how easy it was to become mired in arguments and ideas. I lived it. Maybe that’s why I lost a lot of my hair, and what remains turned gray. As briefly as possible, I will explain what happened and how we came to an understanding about the relative and differential loading challenge.

Note that I am changing the terminology describing this issue. Equalization of the loads on the ropes, if you do it at the logical place (usually with the elevator car parked at its common go-to point, usually the lobby) equalization is still a worthwhile installation and maintenance function. We know that doing this is a good strategy and far better than doing nothing. Doing nothing guarantees only that you could get the worst of all possible results: shortened rope life and another confounding variable impacting the entire system, worn sheave grooves.

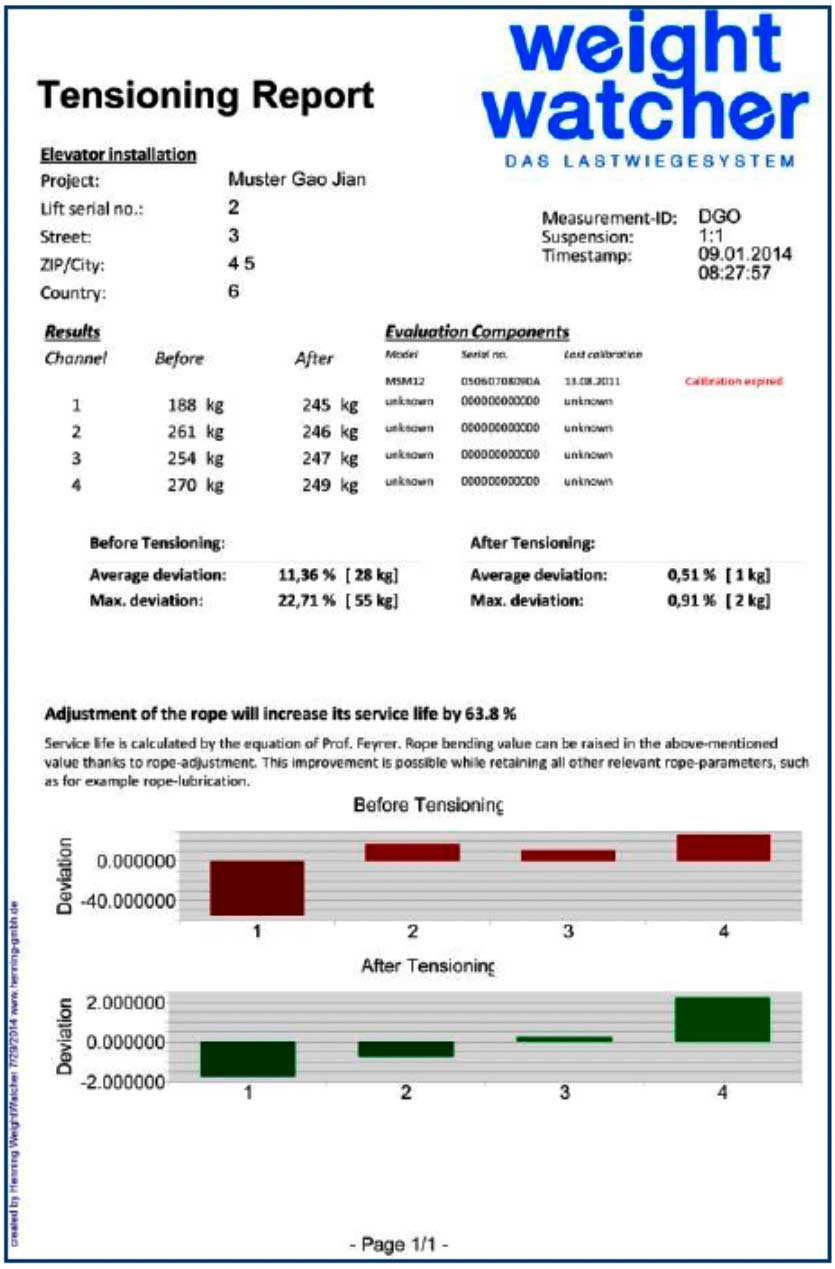

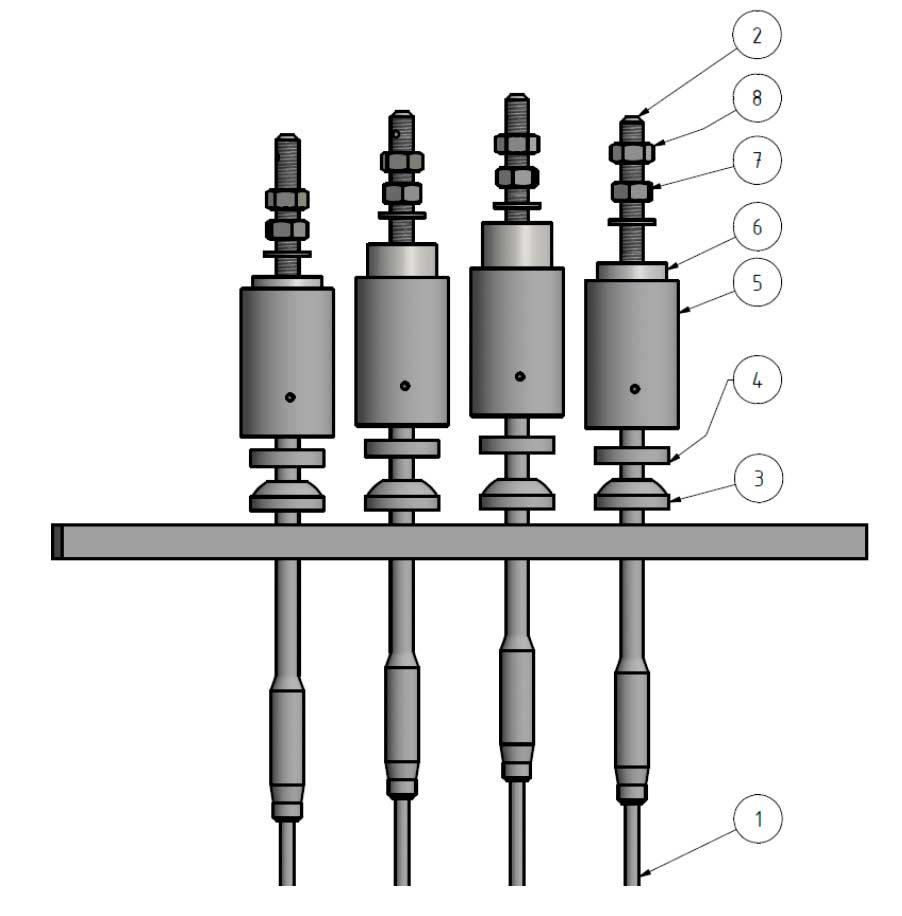

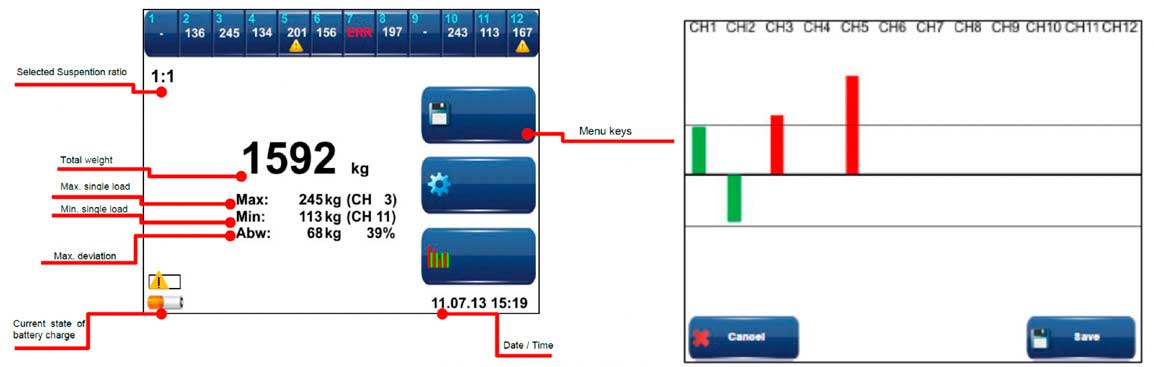

The first step to address this problem became possible only when we were finally able to truly measure relative loads on individual ropes. With this information, one can effectively complete the challenge to equalize a set of ropes (in a new installation and in one we know has not been compromised). See Figures 1, 3 and 4.

This system was designed with specific load-measurement accuracy in mind, and it was tested, proven and validated. With training, using the right rope/belt sensors and following the correct processes, this equipment/system is reliable, repeatable and internally consistent. There are now close to 1,000 users of the Henning Mobile Weight Watcher system around the world.

Those who took the time began to note that whenever “equalization” adjustments were made on ropes, measuring them again could yield completely different results.

Some smart engineers, who also understand elevators and how they work, accomplished the next big step toward understanding suspension-means problems and the full measure of the challenges that go with them. A continuous measurement software program began as an option to their control measurement unit. This option has become a standard feature, along with another formerly optional piece of software for measuring elevator load balancing (weighing CWT and car, inputting the elevator capacity). All this equipment is algorithm-based and software-focused. Measurement reports are easily produced.

The following two examples of reports show the information and data we can produce. The graphic showing a continuous measurement report is especially informative and useful — so useful that it is integral to our current level of understanding of elevators and their suspension means. We’ll discuss this a little more in the third and final part of this column. The takeaway from this discussion is that some elevators really need to be tuned or have an optimized setting of the load applied to each respective rope or belt.

Original Design and the Current State of Elevator Installation

In my time dealing with rope and suspension-means challenges, this is the area of understanding that was most needed, least understood and, often, ignored or denied. Because we have collected and studied data on elevator load balancing (and transfer), we know the important facts and principles.

A first general principle here is that there are elevator systems around the world that were designed with other needs in mind; those needs failed to consider the impact they would have on elevator suspension means. For higher-speed, mid- to high-rise elevators with round ropes, we can see that the issue of load was considered. (We now commonly have 2:1 roped systems.)

Maybe some consideration was given to the impact of smaller- diameter drive sheaves (requiring aggressive groove profiles for traction) but not to the downstream effects of such changes. All systems met the code requirement that the drive/sheave-diameter- to-rope-diameter relationship had to be no less than D:d of 40:1.

Engineers designing such systems likely knew their designs would seriously impact rope life. We see a lot of 40:1 systems in operation now. Those elevators are especially good at executing the bending fatigue of wire ropes. There’s little room left for making a mistake.

We also see MRL designs continuing to be a whipping post for some in the industry, with suspension systems that are as bad as they can be. The load profile of MRL systems (with their extra bends and turns for machines installed in the hoistway or on car tops) is starkly unlike the load exchange differentials we have seen on ultra-high-rise installations (sometimes dramatic).

The short story is that the expected rope life for these types of systems has been calculated and repeatedly proven to be only in the five-seven year range. That’s the best case, even if everything is done correctly and well. I have also seen systems where the calculated life performance is just three years and, in one case, as low as 18 months. If something is not done well (or right) with these “demanding” installations, as in my first point in this column, actual rope life expectancies can be a year or even less.

I lived through a time when just the rope was blamed and each and every manufacturer,at one point or another, was blamed. for a while, each had to suffer as the scapegoat.

Again, not to labor over the technical bits, but you must know the details of your elevator installation if you really want to understand how efficient and successful your suspension means can and will be. When we take some measurements and find the outlook is bad, we need to at least be careful (if not perfect) during installation.

A couple of other remedies should be considered. These include knowing the load profile and using that information to tune the ropes/belts (instead of simple equalization). There are also options to use more resilient rope designs. Many of the new, more demanding elevators can benefit greatly from a set of MCX-9 ropes. Experience has proven that this rope design is good for at least double — and potentially triple — the performance of that of an 8X19 sisal core commodity rope.

First and always, make sure your hoist rope is handled carefully and installed right. Admittedly, achieving a rope life of three years on an elevator where you would have gotten just one year before doesn’t sound so great. But, 10-15 years of productive life from ropes, instead of getting only five before, can make you feel much better. The owner will agree.

One more remedy for having to replace ropes too often is a permanent, dynamic and constant hydraulic adjustment system installed over the ropes. In principle, this idea has been around for a long time. An old friend and colleague, Mike Barnes from Las Vegas, designed and still builds a mobile tool for the hydraulic equalization of ropes. If you’re willing and able to do some extra work and a few calculations, you could also use this system to tune an installation. To do that, you need a continuous measurement profile.

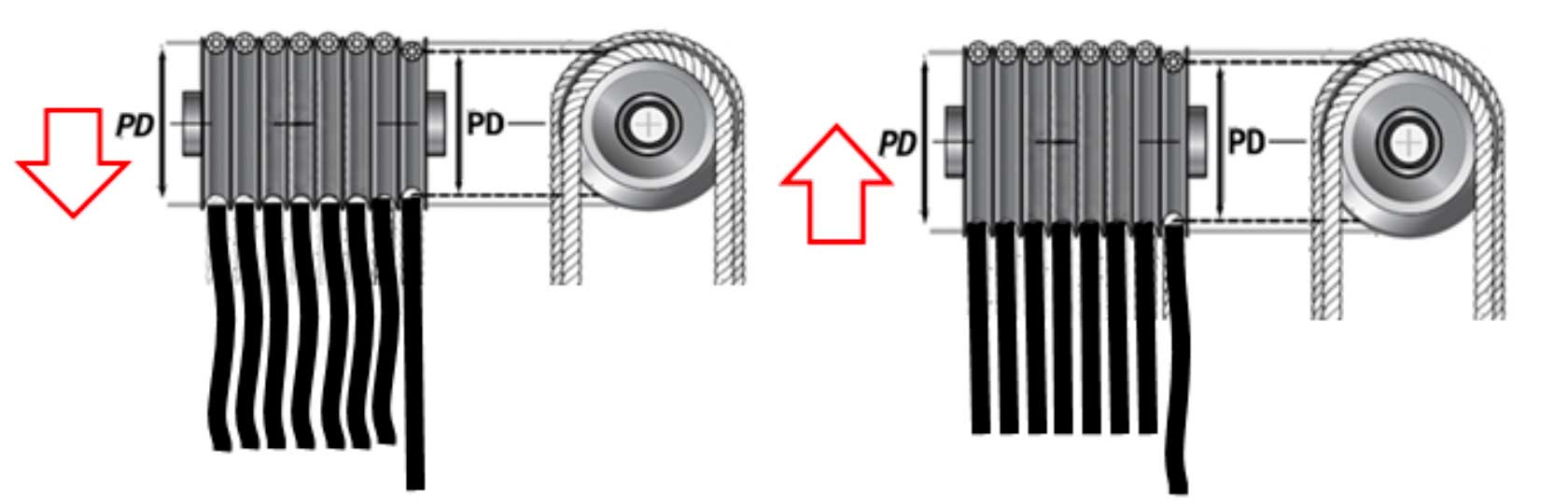

Henning has designed a system that, in principle, can lessen most (and eliminate some) negative impacts demanding elevator systems can have on rope. Figures 6 and 7 show the design principle of this new elevator component and a picture of one recently installed in Atlanta.

I hope I have left the readers of EW with not just ideas, but also solutions for an industrywide challenge. I hope these ideas and options now seem more sane than continuing to do what we have always done (like change rope suppliers)!

Get more of Elevator World. Sign up for our free e-newsletter.