by Vincent H.K. Chow, C.W. Chan, Gary K.Y. Cheung and James C.Y. Lau

This paper was first presented virtually at the 12th Lift & Escalator Technologies Symposium in September 2021 and printed at the symposium website at liftsymposium.org.

Keywords: electrical and mechanical services department, Hong Kong, lift safety, aged lifts, regulator, facilitator, promoter, lift modernisation subsidy scheme, special maintenance

Abstract

Hong Kong is one of the most densely populated cities. There are around 70,000 lifts in operation to transport millions of people in the built environment of the territory. The safety of lifts is dependent on proper periodic examination and maintenance. With rapid technological advancement, modern lifts are equipped with more comprehensive safety devices than the aged ones. Lift modernization could transform aged lifts to deliver more versatile services with enhanced safety, reliability and ride comfort. The Electrical and Mechanical Services Department (EMSD) of the Government of Hong Kong Special Administrative Region (HKSAR) of the People’s Republic of China acts as the “regulator,” “facilitator” and “promoter” for electrical and mechanical safety in the HKSAR. The EMSD has been actively introducing multidimensional measures for uplifting the safety of aged lifts, thereby enhancing public safety. While paying attention to the progress of lift modernization works, the EMSD has stepped up the surveillance of aged lifts and requested the responsible persons and registered lift contractors to step up the maintenance of aged lifts. At the same time, the government has made available financial assistance with appropriate professional support to building owners in need to modernize or replace their aged lifts. In the long run, the EMSD will consider mandating measures for lift modernization by making reference to relevant experience in other jurisdictions, enacting and enforcing similar ordinances in Hong Kong, as well as taking into account the impact on the community and the trade. This paper will share the experience, effectiveness and challenges faced when implementing measures to enhance the safety of aged lifts in Hong Kong.

1. Lift Safety in Hong Kong

Hong Kong is a densely populated city packed with skyscrapers and high-rise buildings, where social activities rely much on its sound and reliable vertical transportation (VT). There are around 70,000 lifts operating diligently to transport millions of people from floor to floor among buildings of which 8,500 blocks are high-rise and about 500 are skyscrapers.[1]

1.1 Lifts and Escalators Ordinance in Hong Kong

The safety of lifts in Hong Kong is regulated by the Lifts and Escalators Ordinance (Chapter 618) (LEO), which was put into operation on December 17, 2012, to replace the repealed Lifts and Escalators (Safety) Ordinance (Chapter 327). The EMSD, as the regulator, enforces the LEO through various means, such as conducting risk-based audit inspections, carrying out prosecution and disciplinary proceedings, promulgating codes of practice as well as registration of contractors, engineers and workers. In addition to being a regulator, the EMSD also acts as “facilitator” and “promoter” for improving lift safety in Hong Kong.

1.2 “Guidelines for Modernising Existing Lifts”

When a lift is put into service for the first time, its design must comply with relevant safety standards prevalent at the time of installation. The latest design requirements are stipulated in the Code of Practice on the Design and Construction of Lifts and Escalators 2019 Edition (Design Code) adopting the requirements of EN 81-20/50. Since the roll-out of the Design Code in 1993, several amendments of the Design Code were made to bring the safety requirements in line with the prevailing international safety standards and meet with technological advancements to make lifts safer.

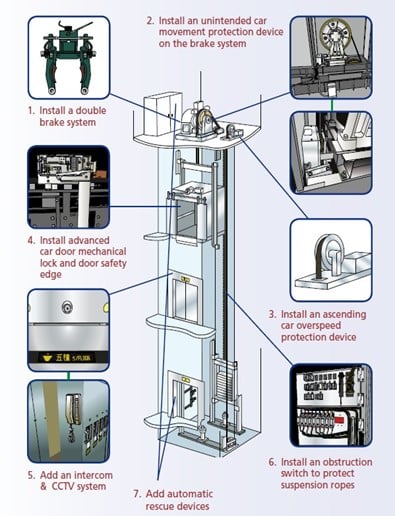

In view of this, the EMSD promulgated in 2011 the “Guidelines for Modernising Existing Lifts” to facilitate owner of lifts to implement enhancement and modernization solutions to make their existing lifts safer, more efficient and reliable and provide better ride comfort. The Guidelines adopted requirements from EN 81-1:1998+A3:2009,[4] introducing seven application solutions for enhancing existing lifts. The first four solutions (namely installation of (i) double brake system, (ii) unintended car movement protection device, (iii) ascending car overspeed protection device, and (iv) car door mechanical lock and door safety edge) were considered essential and were recommended to be taken with priority, whereas the remaining three solutions (namely (v) installation of intercom and CCTV system, (vi) obstruction switch to protect suspension ropes, and (vii) automatic rescue devices) were recommended to be considered according to the actual situation or individual need (Figure 1).

1.3 Aged Lifts and Incidents

As of the end of 2020, there were about 70,000 lifts in Hong Kong, with over 41,000 lifts (about 60%) aged over 20 years and about 45,000 lifts (about 65%) not equipped with all four essential modern safety devices (i.e., double brake system, unintended car movement protection device, ascending car overspeed protection device, and car door mechanical lock and door safety edge). Reported lift incident records in Hong Kong revealed that most of the lift incidents were related to passenger behaviors (Table 1).[2] For those few incidents related to lift equipment fault, most of them were due to poor leveling.

Main Cause of Incidents |

Number of Incidents |

||||

2016 |

2017 |

2018 |

2019 |

2020 |

|

Passenger Behavior |

411 |

449 |

387 |

358 |

225 |

Lift Equipment Fault |

11 |

8 |

15 |

6 |

11 |

Injuries to Lift Worker |

6 |

5 |

2 |

3 |

2 |

Total |

428 |

462 |

404 |

367 |

238 |

Table 1: Reported lift incident records in Hong Kong (2016-2020)

However, there were a few lift incidents causing serious injury to passengers or even fatality.(1) All of those lifts were installed more than 20 years ago, and the serious incidents could well be avoided if those lifts had been equipped with the four essential modern safety devices mentioned before.

In response to the above, especially for the two serious lift incidents involving unintended car movement that resulted in serious passenger injury and death in 2018, the government rolled out a series of measures in June 2018 to enhance the safety of aged lifts.

2. Step Up the Maintenance Works of Aged Lifts

The LEO requires that lifts must undergo periodic maintenance by registered lift workers (RWs) at least once a month(2) and be examined by a registered lift engineer at least once a year to ensure the safe operation of the lifts. As short-term measures to uplift the safety level of aged lifts, the EMSD stepped up the surveillance checks of relevant maintenance items to ensure the quality of the inspection and maintenance works carried out by the registered contractors and introduced special maintenance for the aged lifts in June 2018.

2.1 Surveillance Inspections of Maintenance Works

The EMSD increased its manpower to step up the surveillance checks on the maintenance and examination of aged lifts which have not yet been modernized, i.e., not yet equipped with the four essential safety devices. The number of inspections increased from the earlier level of 11,000 inspections per year to about 29,000 inspections per year, and about 55% of the inspections were concerned about maintenance works.

2.2 Special Maintenance

The EMSD revised the “Code of Practice for Lift Works and Escalator Works”[3] in 2018 to require aged lifts, which have not been equipped with unintended car movement protection devices, ascending car overspeed protection devices or double braking systems, to have “special maintenance” conducted twice a year, unless alternative requirements have otherwise been specified by the manufacturers.

The scope of special maintenance of an aged lift includes:

- Disassembly maintenance of the braking mechanism for the lift machine brake.

- Measure the braking distance by performing no-load brake test to ensure compliance with the lift manufacturer’s requirements.

- Check grooves of traction sheave in the lift traction machine to ensure they are in accordance with the lift manufacturer’s specifications.

- Perform no-load traction test for the lift and measure the leveling accuracy to ensure the traction and leveling accuracy are in compliance with the lift manufacturer’s requirements.

- Check the mechanical locks and electrical contacts of all lift landing doors to ensure they are in safe working order.

The special maintenance is meant to enhance the reliability of the critical components of aged lifts which have yet to undergo modernization. To ensure quality, the EMSD conducted more than 5,000 inspections for the special maintenance works done by registered contractors in 2020.

There was obvious improvement in the performance of aged lifts following adoption of special maintenance and the increased inspections. The irregularities found per inspection dropped by about 50% from the third quarter of 2018 to the first quarter of 2021. On the other hand, the EMSD took the initiative to share statistics and summary of inspection findings regularly with the trade to enhance awareness and drive for continuous improvement in lift safety. The transparency and facilitation have brought greater collaboration with the trade to tackle the safety concerns of aged lifts for the common good of society.

3. Lift Modernisation Subsidy Scheme

The EMSD always takes on the role of “promoter” to publicize improvement and enhancement options and solutions for better lift safety. In 2011, “Guidelines on Modernising Existing Lifts” was published and distributed to lift owners, the trade and other stakeholders, recommending that owners modernize their aged lifts. For further expediting lift modernization, the government launched a HKD4.5 billion Lift Modernisation Subsidy Scheme (LIMSS) over seven years starting from the financial year 2019-20 to provide financial incentives and appropriate professional support to building owners in need to carry out lift modernization works, thereby enhancing the safety of their aged lifts.

3.1 Needs of Aged Lifts Owners

While it is always the primary responsibility of lift owners to keep up and improve the safety of their lifts and to comply with the legal requirements, lifts installed in buildings are commonly used by visitors and the general public, and so enhancing lift safety would benefit the community at large. From publicity events and communications with aged lift owners, the EMSD recognized that some owners may face difficulties in carrying out modernization works due to problems of finance, technical knowledge, organization ability, etc. In view of these difficulties, the EMSD has partnered with the Urban Renewal Authority (URA) to implement the LIMSS, where the URA in Hong Kong allows a very experienced statutory body to undertake, encourage, promote and facilitate urban renewal of Hong Kong, with a view to addressing the problem of urban decay and improving the living conditions of residents in old districts.

3.2 Core Elements of LIMSS

The LIMSS is a new initiative in Hong Kong. The development of LIMSS has directed to the correct focus. The LIMSS comprises the following five core elements:

- Care-based: In view of the ratable values reflecting the condition of buildings and lifts, the LIMSS focuses on providing subsidies to building owners in need by targeting aged lifts at private residential or composite buildings with relatively low average ratable values.

- Safety-based: Priority is accorded to lifts with higher risk, such as lifts having statutory improvement orders or lifts which have not been installed with the safety devices of the prevalent safety standards.

- Resource-based: Having struck the balance between the availability of resources and attractiveness of the financial incentive to building owners, the LIMSS subsidizes 60% of the cost of the modernization/replacement works, subject to a cap of HKD500,000 per lift. Additional subsidies are to be provided for elderly owner-occupiers aged 60 or above, subject to a cap of HKD50,000 per domestic unit of buildings having had the lift modernization.

- Capacity-based: Having regard to the capacity of the industry to avoid inflating market prices and affecting works quality due to the additional lift modernization works, the LIMSS would roll out in an orderly manner to modernize approximately 8,000 lifts in batches over seven years starting from 2019-20.

- Streamlined procedures: As the URA is now undertaking various subsidy schemes for building rehabilitation and fire services improvement works, the government has partnered with the URA in delivering the LIMSS to maximize synergy and facilitate participation by the public.

3.3 Scope of LIMSS

a. Retrofitting of the following “essential safety devices” under the scheme (the first four solutions in the “Guidelines for Modernising Existing Lifts”):

i. Double brake system;

ii. Unintended car movement protection device;

iii. Ascending car overspeed protection device; and

iv. Car door mechanical lock and door safety edge.

b. Addition of the following “optional safety devices” (the last three solutions in the “Guidelines for Modernising Existing Lifts”):

i. Intercom and CCTV system;

ii. Obstruction switch; and/or

iii. Automatic rescue device.

c. Lift drive replacement and associated works where it is technically necessary or more cost-effective in order to install the “essential safety devices” and “optional safety devices” specified above (Figure 2).

d. Owners are granted the flexibility to opt for installation of specified safety devices or carry out complete replacement of their lifts.

e. Subsequent follow-up services during defect liability period for the related safety devices above, but exclusive of routine maintenance services (it is emphasized that the LIMSS is not intended to subsidize lift maintenance services as which should be the sole responsibility of the owner to ensure that lifts are in a proper state of repair and in safe working order).

Free consultancy services would be assigned to the applicant. If the applicant opts to appoint their own consultant to coordinate the lift modernization works, the relevant consultancy fee will be subsidized.

3.4 Technical Assistance and Other Associated Support

Consultants are assigned to participating buildings for pursuing lift modernization works and technical advice services. The services include scope assessment, cost estimation for budgeting purpose, tender document preparation based on standard tender document templates, tendering through e-tendering platform, tender evaluation, works supervision and contract management associated with the lift modernization works.

It is inevitable that building owners’ access would be affected during lift modernization works, especially for buildings with a single lift or with floors served by only one lift. As such, under the LIMSS, the URA has also engaged non-government organizations to provide outreach social services to needy residents, such as the aged and the disabled, of these buildings in order to minimize inconvenience caused to them by the lift modernization works. Such outreach social services include delivery of meals, procurement of daily supplies and provision of stair-climber services, temporary accommodation, etc.

Two rounds of applications for the LIMSS were launched in March 2019 and January 2020. Very encouraging results of applications for more than 8,200 lifts were received, meaning that the launch of LIMSS has correctly addressed the need of building owners.

4. Facilitation and Promotion of Lift Modernization

Equal weight has been given to coordination of the trade and industry and promotion to the public for smooth implementation of the lift modernization scheme, such as LIMSS.

4.1 Attraction of New Blood to the Industry

In accordance with the LEO, all lift works are required to be carried out by RWs or any person under the supervision of an RW. RWs are specialized technicians for carrying out lift works including installation, commission, maintenance and repair works. It was foreseeable that launching of the LIMSS might increase the demand for RWs.

To alleviate manpower shortage in the trade, the EMSD partnered with the Construction Industry Council (CIC) to expand the coverage of the Intermediate Tradesman Collaborative Training Scheme (ITCTS) launched in 2017. Under the scheme, trainees are recruited on a first-hire-then-train basis and primarily trained on-site. This is a six-month training, jointly provided by the CIC and lift companies, consisting of two parts. The two parts are, respectively, a 12-day initial training, giving the trainee general knowledge of background and skills required for performing lift works, and an on-site practical training where the trainee will perform actual works under the guidance of their employers. To ensure the quality and progress of the training, the CIC regularly conducts site visits to the workplace and inspects training progress of trainees by prior arrangement with the trainers. Toward the end of the scheme, trainees will have to complete a certification test to ensure their knowledge and skillsets are up to the requirements before granting certification test bonus. Employers will also receive an employer completion bonus after that.

Trainees, who have completed the ITCTS, will be eligible to join the Advanced Construction Manpower Training Scheme-Pilot Scheme (ACMTS-Pilot Scheme) and proceed on their career path in the trade. The scheme has successfully helped attract young newcomers to the industry, alleviating the manpower demand.

4.2 Promotion of Lift Modernization

Since the release of the “Guidelines on Modernising Existing Lifts” in 2011, the EMSD has started promoting lift modernization via various means for lift owners to uplift the safety standard of aged lifts. To synergize with the launch of LIMSS in 2018, EMSD conducted a series of publicity activities. As revealed in the announcement of public interests, the proper safeguard for aged lifts is not personal protection equipment but, instead, lift modernization (Figure 3). The message of lift modernization, delivered in a laymen’s tone, was direct and easily understood by the general public.

In addition to the television and radio announcements, posting advertisements on newspapers and buses, etc., the EMSD has also delivered and participated in numerous public briefings, seminars, owners’ meetings, district council meetings, etc., (Figures 4 and 5) to promote lift modernization and lift safety.

4.3 Facilitation To Upkeep Lift Safety with Technology

As one of six smart areas under the “HKSmart City Blueprint” induced by the government since 2017, the “Smart Government” concept has guided the EMSD to have more initiatives on adoption of technology for enforcement of legislative requirements as well as facilitating the trade to use innovative technologies on their daily works. The EMSD launched the E&M InnoPortal(4) (F6), which lists the service wishes of various government departments, public organizations and the electrical and mechanical trades, and invites the I&T sector, including start-ups and universities, to propose relevant I&T solutions for matching. Up to June 2021, more than 750 I&T solutions and 350 I&T wishes were collected for matching, and over 130 trial projects were started and completed in the past few years. One successful matching between I&T solutions and wish items on the portal is the development of an e-logbook of lifts and escalators.

In Hong Kong, it is a statutory requirement for responsible persons(5) to keep and maintain a logbook for their lifts. The logbook must be in the specified form, containing information such as: (i) description of the lift, (ii) name and contact details of registered contractors who undertake maintenance works and (iii) particulars of every incident of the lift concerned. Responsible persons are required to keep track of the entries of the logbook to ensure works by registered contractors are accomplished and on schedule.

There are approximately 26,000 conventional paper-bound logbooks in Hong Kong. Some responsible persons may pay less attention to the statutory requirements for the upkeep of logbooks, leading to unnecessary sanctions or warnings, while other responsible persons may find paper-bound logbooks cumbersome to trace and summarize different maintenance logs and occurrences for monitoring and ensuring timely execution of lift works. Thus, a new way of logging and analyzing the data has been proposed by the EMSD.

For facilitate stakeholders to better manage, analyze and monitor lift works, the EMSD has proposed developing a common electronic platform, viz., digital logbook, to replace the paper-bound logbooks. The digital logbook will be accessible on both mobile devices and desktop computers, adopting a newly designed user-interface, offering user-friendliness and easy information access to responsible persons and trade personnel. It can also strengthen the government’s monitoring/regulatory control as well as encourage compliance and enhance works quality. The system, capable of uploading images, audio and video of lift works carried out, will aid incident investigations and equipment fault analysis. The works and entries recorded for each lift generated every day will be analyzed for insights leading to setting performance indicators for quality assessment, better strategic regulatory moves and policies for healthy trade developments. Automatic alerts will be dispatched to responsible persons and registered contractors, reminding them of the statutory activities and the relevant submissions that are due and safeguarding stakeholders from contravening the legislative requirements. All in all, the digital logbook, combined with big data analysis, will facilitate all trade parties in working hand-in-hand to enhance lift safety.

5. Conclusion and the Way Forward

Looking at the long run for addressing the safety issues of aged lifts, the EMSD has been studying the feasibility of mandating measures for lift modernization. The EMSD will make reference to relevant experience in other jurisdictions, the enactment and enforcement of similar ordinances in Hong Kong as well as take into account the impact on the community and the trade in formulating the resolution proposal. In this connection, EMSD will consult the public, legislators and the trade in due course.

Recently, the EMSD has conducted a benchmarking study to review 10 overseas jurisdictions (i.e., Germany, Belgium, France, U.K., NYC, California, Tokyo, South Korea, Singapore and Shenzhen) on regulatory measures about aged lift modernization. The study results reveal that financial subsidy and mandatory risk assessment of modernization are two major measures to drive upgrading or replacement of aged lifts. The EMSD would further explore the possibilities of adopting similar measures in Hong Kong.

References

[1] The mysterious world (2021) Top 10 Cities with Most Skyscrapers 2021 [Online]. Available at: https://themysteriousworld.com/10-cities-with-most-skyscrapers [Accessed May 31, 2021]

[2] Electrical and Mechanical Services Department (2021) Reported Lift Incident Records. [Online]. Available at: https://www.emsd.gov.hk/en/lifts_and_escalators_safety/publications/contractors_performance_rating/reported_lift_incident_records [Accessed May 31, 2021]

[3] Electrical and Mechanical Services Department, Code of Practice for Lift Works and Escalator Works (2018 Edition). Available at: https://www.emsd.gov.hk/filemanager/en/content_805/CoP%20on%20Lift%20Works%20and%20Escalator%20Works%202018%20Edition%20(Eng).pdf [Accessed May 31, 2021]

[4] British Standards Institution (1998) Safety rules for the construction and installation of lifts — Part 1: Electric lifts. BS EN 81-1:1998+A3:2009. London: BSI.

Footnotes

(1) There was a fatal case in 2018 due to uncontrolled car movement of an aged lift.

(2) In actual practice, most responsible persons require registered lift contractors to organize RWs to perform periodic maintenance for their lifts twice a month.

(3) Full API of LIMSS available online at isd.gov.hk/eng/tvapi/19_eg91

(4) The E&M InnoPortal inno.emsd.gov.hk/en/home

(5) According to the Lifts and Escalators Ordinance (Chapter 618) in Hong Kong, the responsible person for a lift is defined as (1) the owner of the lift; or (2) any other person who has the management or control of the lift.

Also read: Future Modernizations

Get more of Elevator World. Sign up for our free e-newsletter.