Well-Connected

Sep 3, 2021

JLPL GM shares insights on the significance of providing VT for the Sir M Visvesvaraya Terminal at Bengaluru.

India continues to invest in developing urban infrastructure to take on the urbanization challenge and make cities more livable and smarter. In the Union budget of 2021, the government of India allocated Rs2.33 lakh crore to support its long-term transport infrastructure plans out of which Rs1.10 lakh crore alone was allocated to railways as a capital expenditure.

The railway system had to efficiently use the land in Bengaluru for a project that would support future population levels, and address the transportation and connectivity needs of not just the urban population but the daily population into the city, as well.

This push in infrastructure growth by the government has led to the rolling-out of some unique and aspiring projects that are planned to support and withstand the continuously growing needs of the rural and urban population.

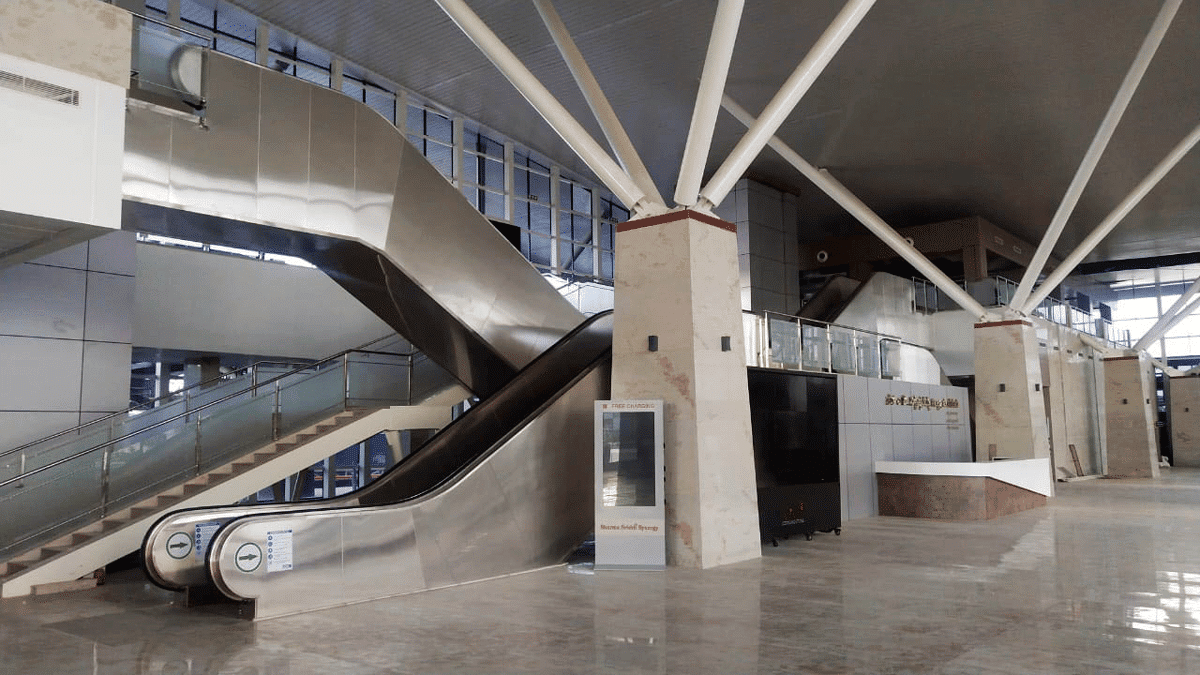

One such project is the Sir M Visvesvaraya Terminal in Bengaluru near the Baiyappanahalli Metro Station, which is similar to the Kempegowda International Airport. This facility is India’s first fully air-conditioned railway station.

The National Commission on Population (NCP) in India predicts that by 2036, about 38.6% of Indians (600 million) will live in urban areas. The UN, too, highlights that India’s urban population size will nearly double between 2018 and 2050, from 461 to 877 million. Therefore, the railway system had to efficiently use the land in Bengaluru for a project that would support future population levels, and address the transportation and connectivity needs of not just the urban population but the daily population into the city, as well.

This terminal is designed to be aesthetically rich in line with modern infrastructure and support daily travel needs. It eases the congestion between the present KSR and Yeshawantpur railway stations and distributes the flow of travelers among the three stations.

To efficiently manage the movement of people within the terminal, Johnson Lifts Pvt. Ltd. (JLPL) was selected to provide elevators and escalators for this project. JLPL installed two lifts of 20-passenger capacity, with stainless-steel mirror finishes and glass doors, as well as four heavy-duty escalators.

The JLPL team engaged with the railway team while the project was still on the drawing board, consulting the designers and architects on the optimum vertical-transportation (VT) solution. The efforts of this collaboration can be seen, as the solution provided by JLPL complements the terminal infrastructure. This has simplified people-movement across levels instead of the complex challenge that would otherwise have been posed at a busy terminus.

There were many reasons JLPL was selected for this project, including:

- four global-standard manufacturing units that create world-class lifts and escalators

- experience completing VT projects for:

- Large government infrastructure projects across India, such as metro stations, airports, railway stations, bus terminals, smart cities, office buildings, etc.

- Apartments and individual homes

- Commercial complexes, malls and hotels

- Corporate offices

- Hospitals and educational institutes

- 54 branch offices across India, the Middle East, South Asia and East Africa and 174 service centers pan India

- Highly experienced and trained teams

Much of JLPL’s experienced staff has been with the company for more than three decades. These veterans guide younger employees to help ensure company strength and longevity.

Safety of the equipment is the top priority, and it is the key parameter around which all processes are developed.

AT JLPL, all departments, from front-end sales and manufacturing to delivery, safety, installation, service and support, are brought together for every step of a new project. The activities during the course of a project are driven by set procedures, time-tested processes and optimal timelines. Safety of the equipment is the top priority, and it is the key parameter around which all processes are developed. Unique projects like these need to have a design-and-built approach. JLPL’s organizational setup (R&D, manufacturing, project management and aftermarket) helps the company provide efficient solutions.

The company has a network of service centers across India, which is key to the aftermarket performance (safety as well as reliability) of the equipment. The company has also developed systems and processes using technology to its advantage to solve critical issues, such as minimum down time, spare availability, etc.

The 43,650-ft2 location of JLPL’s National Service Stores (NSS) at Chennai is connected to all the branches, enabling the inventory of spares to be monitored online. We have 174 service centers and six training centers across India, and all branches have their own service store for which the service spares will be catered by the NSS. In addition, NSS is also equipped with an in-house inspection-cum-repair center.

Some of the notable services provided are:

Quick Response Service: JLPL works with Mobile Store Vans for quick dispatch.

Smartphone Service: We have introduced our Quick Service app, where jobs are pushed to the service engineer’s smartphone and materials can be ordered. Customers sign off on the satisfactory conclusion of the job on the smartphone, too.

This project was a one-of-its-kind in the country. The core strength of JLPL is adhering to timelines and fast turnaround on installation, testing and/or servicing. Our focus for every VT project is providing smooth, noiseless, vibrationless, comfortable rides, with traveler safety being the most important factor.

Get more of Elevator World. Sign up for our free e-newsletter.