Widening the Perspective – From Energy to Resources

Oct 1, 2017

Insight into sustainability and environmental impact

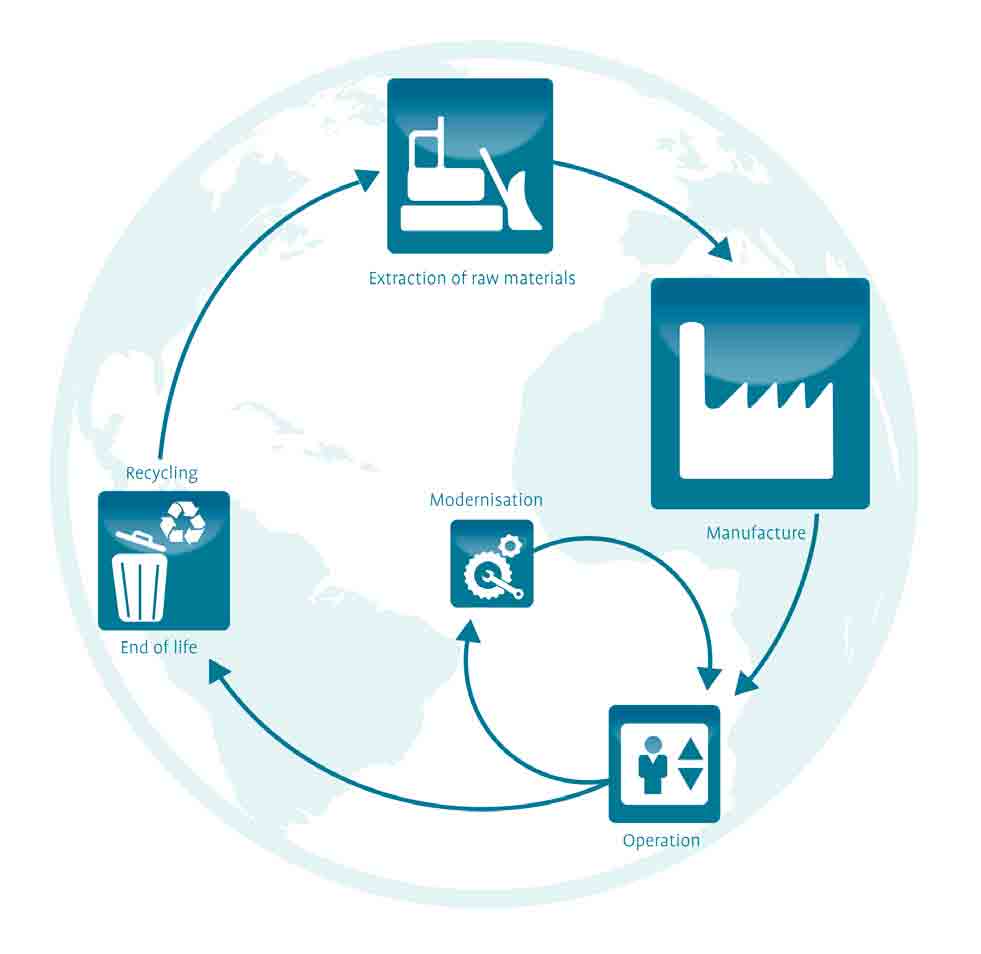

A company’s energy consumption is often used as the sole criterion for its energy efficiency. The reality is much more complex, however, and behind this limited viewpoint lies a potential for environmental optimization that is very far from exhausted. To assess a product’s environmental sustainability, we need to consider its entire lifecycle and deal with the subject of “gray energy.” Gray energy is the total amount of nonrenewable primary energy consumed by all upstream and downstream processes, including the energy consumption of all production processes used. A large, often unconsidered part of our energy consumption is (sometimes hiding) in this area. On the other hand, the ongoing energy costs for operation are often regarded as being of little importance when looking at the bigger picture. To reduce overall energy consumption by a significant amount, however, it is important to recognize and exploit the enormous potential in using raw materials efficiently and extending the service life of products.

Sustainability and Environmental Footprint: Modernization Versus the Throwaway Culture

Humans currently consume one-and-a-half times more resources as the Earth can provide. To help counteract this, the environmental footprint method serves as an indicator of environmental sustainability. By depicting the CO₂ balance quantitatively and the area requirement qualitatively, it can provide a pictorial representation of resource consumption. For example, when thinking about climate protection in the purchase of a new car, it should be considered that the CO₂ balance will not be improved by it until it has been driven 300,000 km. Even then, it is only when the new car uses at least 1 l less fuel per 100 km (6 mpg more) than the old one.

Companies committed to environmental responsibility need to recognize that the pursuit of energy efficiency is only a small part of a higher-level strategy for resource efficiency, which includes the careful and efficient handling of natural raw materials and the ratio of a benefit or result to the resources used to produce it. The idea is to “make more from less” in terms of global dealings with all resources.

The life expectancy of apartment buildings is assumed to be 60-85 years, whereas the corresponding figure for an elevator is only 15-20 years. To assess the resource efficiency or sustainability, the entire lifecycle of a building (not just the lifespan of the elevator installation) should, therefore, be taken into account. But, to be energy efficient during operation, as well, it is important to identify the right drive for the application early in the planning phase. Bucher Hydraulics offers these advisory services, from the important first step (the thorough analysis of system data) through the presentation of various possible solutions, up to the use of appropriate tools for visualizing energy requirements. The parameters essential for energy efficiency in the operation phase are the energy consumption during travel and in standby mode. Many years of experience and technical expertise on the part of the elevator partner are the key to individual modernization packages.

Sustainability With Hydraulics

When sustainability (not simply the energy efficiency during operation) is made the decisive criterion in the planning of the elevator system, all roads will inevitably lead to a hydraulic solution. A decisive contribution to the reduction of the environmental footprint can be made with easily implemented modernizations, which can be carried out several times during the lifetime of the building.

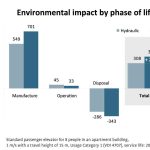

In summary, for a standard passenger lift in an apartment building, and under the conditions shown in Figure 2, we can say:

- The manufacture of an elevator system has a significantly greater impact on its environmental footprint than the total operating time.

- Due to the high material intensity and high consumption of gray energy, a complete renewal is significantly less sustainable than a modernization.

- The complete replacement of a hydraulic elevator by a roped elevator from the perspective of the operation phase on its own is well intentioned, but, from the environmental viewpoint cannot be justified.

- Figure 1: A depiction of the small impact of modernization on the environmental footprint of an elevator’s lifecycle; a modernization is more ecological than a replacement.

- Figure 2: Distribution of environmental impact: when considering the whole lifecycle, the hydraulic elevator has a significantly smaller impact on the environment than the roped elevator.

Get more of Elevator World. Sign up for our free e-newsletter.