Wire Rope Tension

Sep 1, 2015

Importance, measurement and maintenance are addressed.

Since the invention of elevators with multiple ropes, equal rope tension has always been important to the proper operation and safety of an elevator. When rope tensions are not equal, the following can occur:

- Noise and vibration, resulting in poor ride quality

- Premature rope fatigue and failure

- Uneven and premature sheave wear and failure

- Loss of traction

- In worst cases, ropes jumping off sheaves and becoming entangled in the machine room and hoistway

Unequal rope tensions can lead to a poor elevator experience for the riding public; costly/expensive repairs for the elevator maintenance company and building owner; and, worst of all, an unsafe elevator. For machine-room-less elevators containing multiple pulleys, bends and turns, equal rope tension becomes even more important.

ASME A17.1 has addressed the issue in paragraph 8.6.4.1.3 of the 2013 code, mandating that elevator rope tension be maintained to certain limits and percentages. Now, the question is, how do we determine and measure rope tension? Many OEMs have incorporated their own solutions, especially on elevators using belts or other types of suspension means. On wire-rope applications, however, there are several options.

The old, and probably still utilized, method is to pull and push the rope to guestimate tension by feel and/or pluck the rope with a mallet and listen to its tone and time the number of vibrations or oscillations. This is not very accurate. It is also very time consuming, especially if one is tensioning an eight-rope machine.

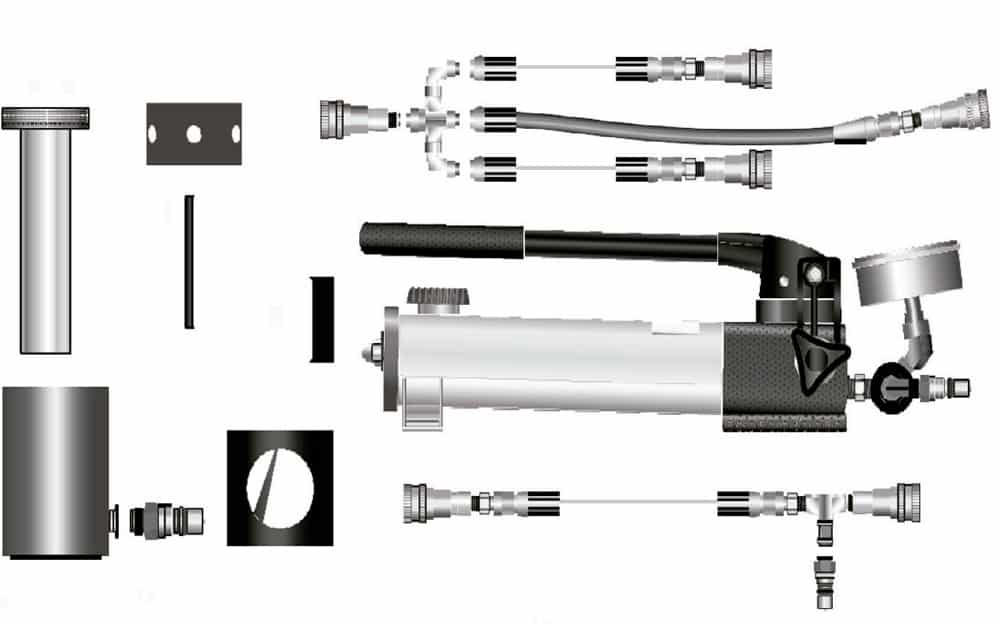

The next method is to use a mechanical device that places a force on the rope to allow one to read a tension measurement (Figures 1 and 2). While it might not give the exact tension of the rope, it will provide an accurate reference to measure the tension of each rope. One drawback is when one adjusts the tension of one rope, it affects the tension of all others. So, one must continually check each rope until all ropes are in relative tension. This can be time consuming and tiring, to say the least. Results are also dependent on a user’s skill level and the device’s placement on the ropes.

A more scientific and accurate method is to install a mechanical device that adjusts the wedge sockets and tension by applying equal force to the shackles (Figure 3). By attaching hydraulic cylinders to the sockets and applying equal hydraulic force to all the cylinders, rope tensions are mechanically equalized (Figure 4). This is a very simple, accurate principle. It can be cumbersome and initially expensive, but is a reliable rope-tensioning method.

A more recent method for rope tensioning is an electromechanical system. There are portable devices that can be brought to any jobsite that allow you to measure the load on the individual ropes, adjust them accordingly and leave them on the system. Rope sensors (Figure 5) are installed on the wire ropes. They are used to sense rope tension and load. The sensors are easily installed onto ropes using an open-end wrench or tool supplied by the manufacturer. There should be one sensor installed for each rope on the elevator. Connection of the sensor to the control is via a USB port.

A programmable load-weighing control is installed to accept signals from the rope sensors and convert them into useable data for the elevator controller and elevator contractor (Figure 6).

A properly integrated load-weighing system provides continuous information to the elevator controller. By doing so, one may:

- Protect the passenger and elevator equipment from overload

- Pre torque the motor to ensure smooth operation when leaving each floor or landing

- Maximize elevator operation by ignoring hall calls with a full cab or ignoring car calls with an empty car

With a properly integrated load-weighing system that includes rope-tension capability, one may:

- Easily check the tensions of each rope by accessing the controller’s program

- Monitor the tensions so maintenance personnel can be notified and dispatched to inspect the elevator and/or adjust the ropes if they become unequal

- Easily view and adjust rope tensions in real time

A more recent innovation is a controller that allows connection of the load-weighing control via a Wi-Fi connection using a phone or laptop. This enables the mechanic, upon arrival to a jobsite, to review the load-weighing controller settings, including rope tensions, without boarding the car.

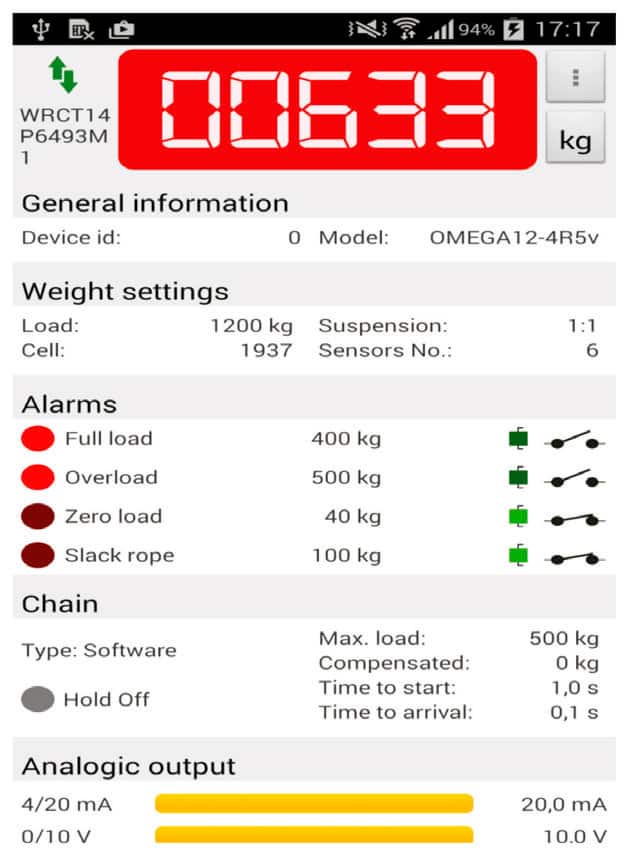

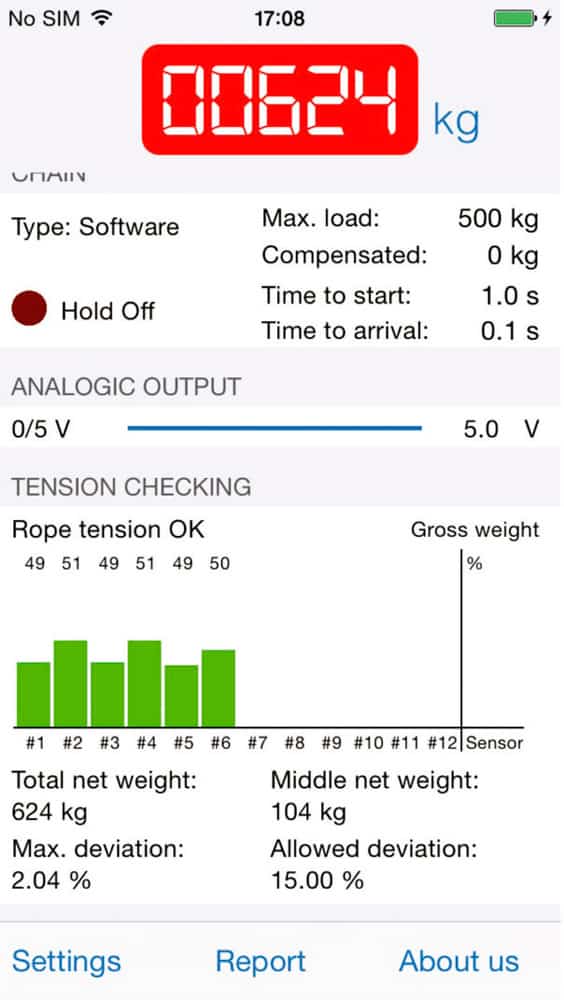

Figures 7 and 8 are sample screens as viewed from one’s phone. From this screen, one will be able to determine:

- Load in the car

- Load settings for the various contact trip points

- Whether any alarms have tripped and, if so, which one(s)

- Contact settings, whether normally open or normally closed

- How many rope sensors are programmed and being used

- Analog output settings used for pre torqueing

- Load or tension on all ropes in actual load or percentage of load

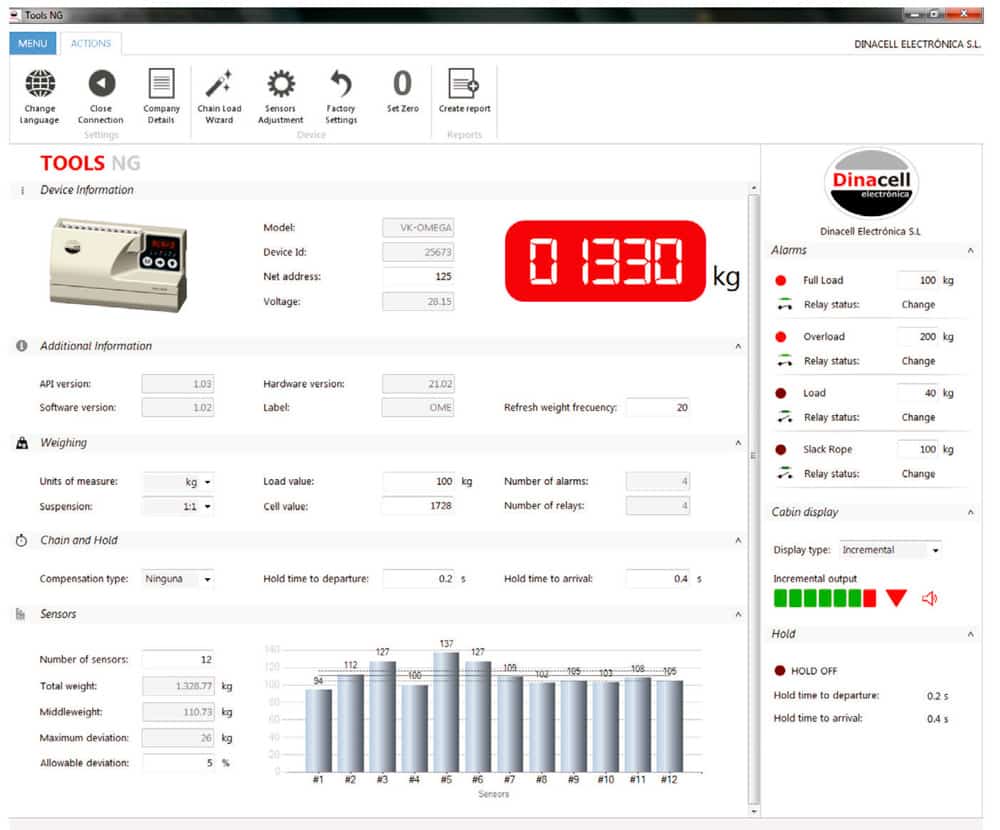

The laptop screen is similarly as inclusive (Figure 9) specifically showing the same data as the phone screen.

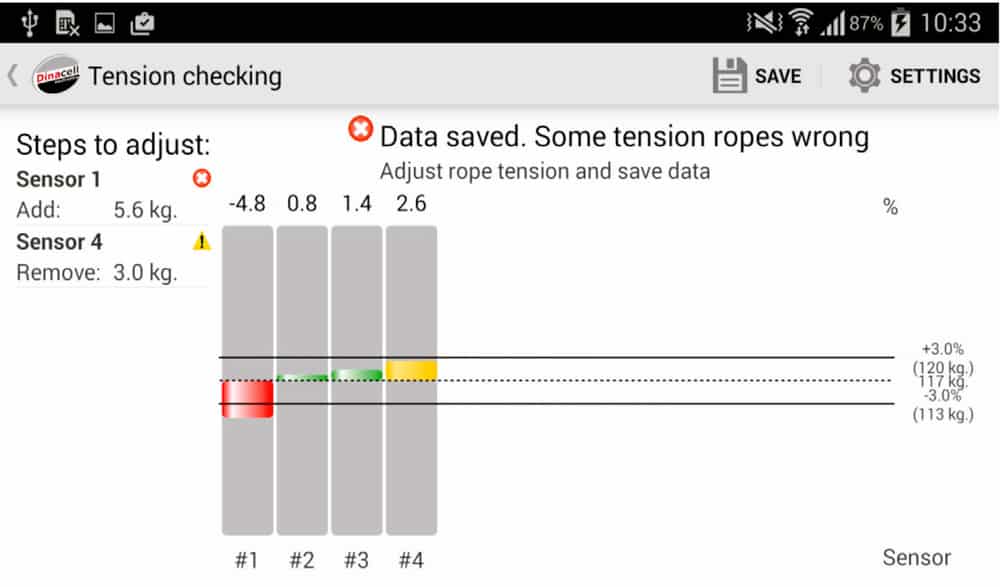

From this connection, one can also program the control, modify settings and use the program to visually watch the rope tensions change when adjusted. There is also an additional portion to the program that will help determine which ropes need to be adjusted and how much they must change to achieve equal tension (Figure 10).

Once the adjustment procedure is correct, the screen updates to show the ropes are tensioned properly and there are no adjustment steps required (Figure 11).

After completing the adjustment, final results may be confirmed by looking at the rope-tension screen and reviewing the tension of each rope (Figure 11).

Finally, one can save a formal report that provides all the controller settings for each elevator onto one’s laptop or smartphone and, of course, print, email or send the report like any other PDF document.

During regular maintenance visits, one can compare previous report settings for a specific job, while viewing the current settings in real time, enabling the mechanic to determine if any changes have been made to the program or if there are any preventative-maintenance issues that need to be addressed.

Whichever method one uses to equalize rope tension, it is imperative the following be inspected, adjusted and/or replaced:

- Sheave grooves, to ensure all are of equal depth: one should use a micrometer or other type of device that can accurately measure and compare groove depth.

- Rails or guides which must be properly aligned: the elevator must be able to run smoothly throughout the hoistway without drag caused by uneven alignment.

- Ropes which must have parallel, vertical alignment: sheave bearing wear, improper modifications to an elevator and components can lead to unparallel ropes.

- Ropes must also be checked for unequal diameters caused by issues such as rope-core failure and uneven groove wear.

- Springs on socket assemblies which must be in working order without interference among one another.

If any of the above items are not checked and issues exist, equal rope tensioning will be very difficult to achieve and, once adjusted, will not last.

Get more of Elevator World. Sign up for our free e-newsletter.