Wittur SA Open House in Argentina

Oct 1, 2011

Wittur SA of Argentina demonstrated its newly reorganized production line for select guests in July.

On July 8, Wittur SA of Argentina opened its doors to customers to show them the new organization of its production line. The changes are intended to shorten delivery times of their elevator products, implementing the Kan-Ban system to manufacture products “just in time” with minimum stock. The event was at-tended by guests from Latin America joined by many customers with companies located in Buenos Aires and surrounding areas. Wittur SA man-agers were accompanied by Javier Navamuel and Jesús de la Peña, who came from abroad on behalf of the global Wittur Group.

Visiting the Production Area

In Argentina, Wittur’s manufacturing area has been increased to 12,000 m2. It has been necessary to reorganize the space to achieve maximum efficiency to better serve the increased and diversified product demand.

The showroom, located at the en-trance of the premises, features the most important elevator components manufactured onsite. Here, visitors were organized into small groups to tour the factory. Guided by commercial assistants, each group could appreciate the manufacturing activities in each section. Visitors received detailed explanations of each process at various stations, including steel-sheet bending, and punching and welding of door and car panels, including the epoxy paint tunnel. In the next station, visitors watched the standard and special car assembly, then arrived at the main warehouse. Here, the procedures are carried out by planning and visual management. There are many Kan-Ban pieces and an extended display of a double-box system for component storage. The warehouse is one of the pillars that enables the factory to work “just in time.”

In each of the stations, the visitors were pleasantly surprised by musicians, equilibrists and acrobats that added an artistic note to the cold technology. After the short performance, the guide started the description of the manufacturing process carried out in that section, stressing the explanations on the use of the Kan-Ban system for component production.

In the Lecture Room

The Wittur Group Presentation

After touring the factory, visitors were served snacks on a sunny terrace. It was a most attractive meeting point to socialize with colleagues. Then, each group entered the lecture room in turns. They were received by de la Peña, the Wittur Group Corporate Lift Systems Product manager, who was in charge of the general introduction of the group and its activities. He described the Wittur Group as the most important global component manufacturer for the entire elevator range, and, after recalling its foundation in Italy 30 years ago, he announced the company has 12 manufacturing plants in Latin America, with factories in Argentina and Brazil. Each produces specific products and 18 distribution centers guarantee closeness to the customers to efficiently meet their needs.

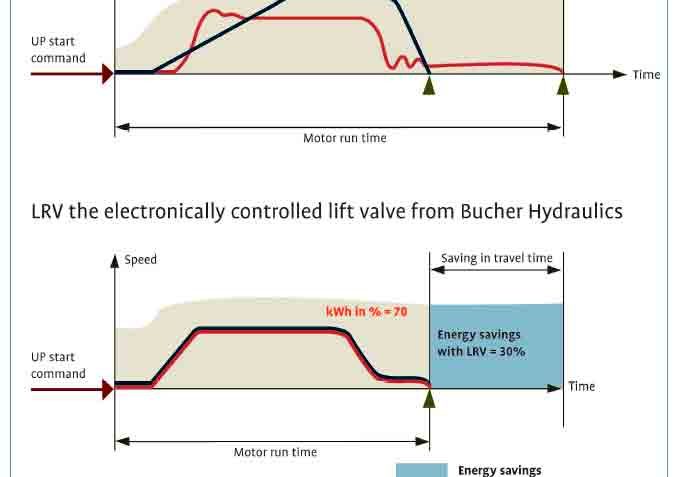

Wittur products comply with all safety requirements for both new installations and modernizations according to the enforced standards existing in each country. At present, ecology and protection of the environment are targets at which the company aims its efforts. It has received the Class A Energy Efficiency Certification for some of its lift systems.

De la Peña went over the Wittur products and their different applications, such as doors, gearless machines with permanent magnets, safeties – including the new electronic governor to avoid uncontrolled car movements according to EN 81-PESSRAL – machine-room-less electric and hydraulic equipment, cars and complete kits. He also showed some figures to demonstrate the group’s production capacity, which includes 690,000 landing doors, 118,000 car doors, 81,000 safety gears, 15,000 hydraulic equipment, 1,700 electric equipment and 3,000 systems.

As a final illustration, de la Peña displayed pictures of emblematic buildings from around the world where the vertical transportation features Wittur components. “The Wittur Group backs up highly qualified personnel at Wittur in Argentina, a partner in whom you can trust your business,” de la Peña concluded.

Innovations at Wittur in Argentina

Ángel Martínez – an official of the Wittur SA Engineering Department – presented the first selection of standard elevators assembled with components manufactured with the Kan-Ban system. They are electromechanical elevators with certain peculiarities. This is one of the first steps leading to a broader use in the range of electric and hydraulic kits. At present, two types are available: 450-kg capacity with 1,100 X 1,300 mm cars and 600-kg capacity with 1,100 X 1,400 mm cars. The counterweight can be installed at either the rear or on one side of the hoistway. The doors can be epoxy painted or stainless-steel cladded.

Martínez then described how to use a catalog that was given to all visitors. Each page in the catalog describes one type of equipment and its components, hoistway and machine-room sizes. The customers can choose the ele-vator according to their needs, indicating the travel, stops, door opening and counterweight location. The customer chooses whether the controller is supplied or not. The goal of this new method is to reduce delivery terms. The combination of the catalog and the use of Kan-Ban helps ensure the availability of pieces in stock to build the ordered equipment and ship it within 15 days.

What Is the Kan-Ban System and How Does It Work?

The Wittur Group has kicked off a program to unify and simplify the production in all of its factories around the world. This decision shows the clear option of the group in favor of the “Lean” philosophy. This program imple-ments the “Lean-Manufacturing System” in all factories, creating a working team made up of the most qualified engineers in the group. The engineers are in charge of the use of the Kan-Ban system on a global level. The program is harmonized in the production centers with a clear ori-entation toward customer satisfaction and reducing the delivery times of its products.

The Kan-Ban system is a mass production manufac-turing method of Japanese origin that means “num-bered card,” or “identity card.” It was created by Toyota Motor Co. as a tool in the development of “just in time” manufacturing.

It is a signal system based on the use of cards that in-dicate the need of an article or component, and it starts its production or supply in the factory. In this way, a con-tinuous production flow is kept, reducing the stock to a minimum and accelerating delivery of the final product.

How It Works

A small stock of every item sits in a fixed allocation in the warehouse. When the customer places a purchase order, he or she “pulls,” or asks for stored items. The Kan-Ban, or signal, travels electronically to the starting point at the manufacturing line to order a new component or product. At the same time, this signal indicates that the stock must be refilled. The Kan-Ban system determines production on demand, and the rhythm of production is determined by the rhythm of Kan-Ban circulation, which, in turn, is decided by the rhythm of products shipped after the production flow.

The main goals of the Kan-Ban system are to:

- Control the internal fluctuations of the demand and the volume of production in each section

- Reduce the fluctuations of the finished product stock to reduce storing costs

- Decentralize the factory’s management, creating the conditions to concentrate on production and stock

- Produce the required quantities just in time

The Dinner Party

The open house was rounded off with a gourmet dinner served at an elegant hotel in Buenos Aires. More than 200 guests were welcomed by Ing. Eduardo Canals, Wittur SA’s general manager, who thanked them for their interest dur-ing the visit. He renewed his commitment to meet customer requirements in an efficient way with prompt delivery. In his turn, Navamuel – Wittur executive vice president and board member responsible for Latin America – stated, “I am hopeful regarding the situation in Latin America and the Wittur Group operations in the region.” In addition to remembering the long-lasting association between Wittur and Soimet, he addressed affectionate words to Nicolás Vrdoljak and Walter González who were present at the dinner party.

After an excellent comedy show, there was enough time for toasts and a farewell that extended to cheerful conversation among many guests who were reluctant to interrupt such an agreeable night.

Get more of Elevator World. Sign up for our free e-newsletter.